Anti-detonation, fireproof, insulating and noise reduction ocean platform bulkhead structure

A technology for offshore platforms and bulkheads, applied in the field of marine engineering, can solve problems such as failure to meet explosion resistance, fire prevention, insulation, noise reduction, failure to achieve shock absorption effects, and no good buffer area for bulkheads, etc., to achieve excellent vibration reduction Noise reduction, convenient quality inspection, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

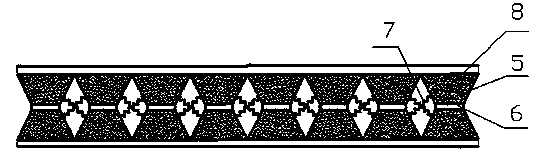

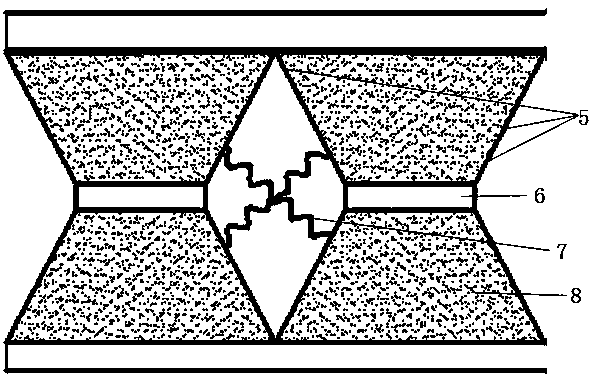

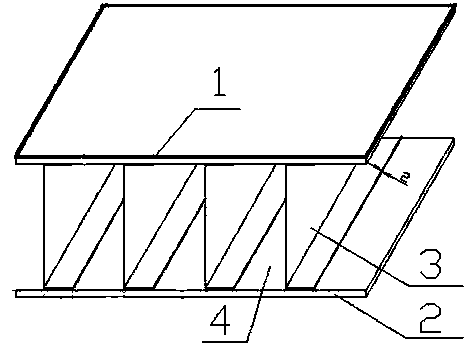

[0030] Such as figure 1 , 2 As shown, an offshore platform bulkhead structure with anti-explosion, fire prevention, insulation, and noise reduction includes a pair of sandwich plates arranged in parallel up and down and an impact-resistant structure. The impact-resistant structure includes three leaf springs 5 respectively. The upper and lower trapezoidal groups are provided with damping material 6 between the upper and lower trapezoidal groups, and the adjacent upper and lower trapezoidal groups are connected by shock-absorbing springs 7, and the interior of the upper and lower trapezoidal groups is filled with the first filler 8; the sandwich plate includes a pair of parallel The upper and lower skin panels 2, the outer surface of the skin panel 2 is coated with an insulating layer 1, a sandwich panel 3 is sandwiched between the two skin panels, and the gap between the sandwich panel 3 and the skin panel 2 is filled with a second filler 4.

[0031] In order to reduce the...

Embodiment 2

[0040] Such as Figure 4 As shown, the longitudinal section of the sandwich panel 3 in this embodiment is I-shaped. Others are the same as embodiment 1.

Embodiment 3

[0042] Such as Figure 5 As shown, the longitudinal section of the sandwich panel 3 in this embodiment is V-shaped. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com