A bulkhead of a ship's superstructure capable of resisting blast and noise

A superstructure and ship technology, applied in the direction of hull bulkheads, ship construction, hull, etc., can solve the problems of ship equipment structure acoustic vibration fatigue damage, affecting the normal operation of instruments and equipment, affecting environmental comfort and other problems, to achieve convenient coating. Effect of decoration construction and quality inspection, excellent living environment, simple painting construction and quality inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, content of the invention will be further described:

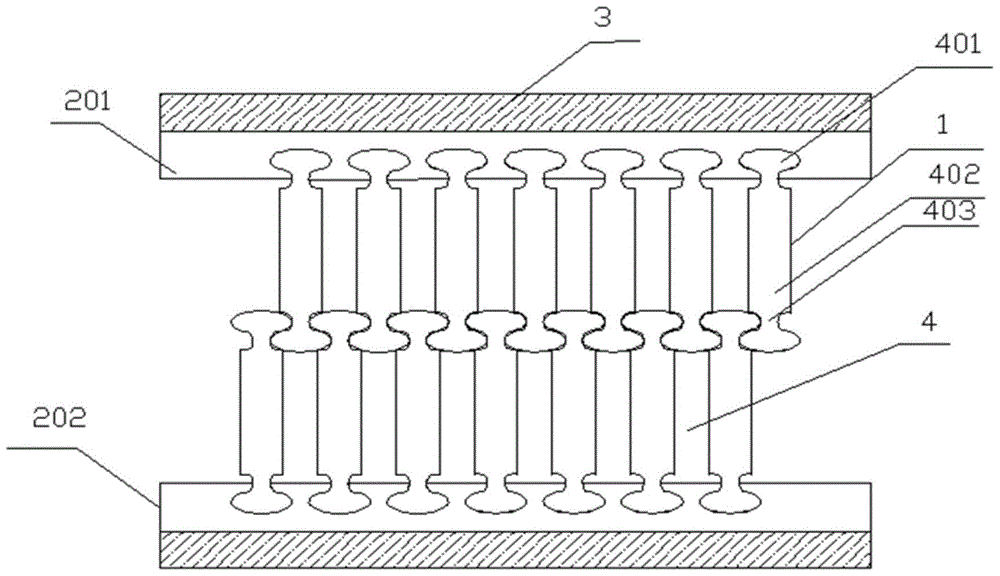

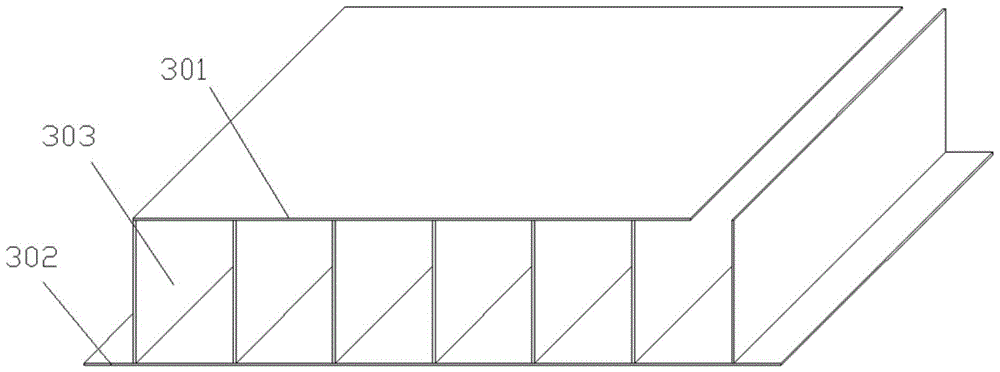

[0031] refer to Figure 1-Figure 10 As shown, the bulkhead of the anti-blast and noise-proof ship superstructure, the bulkhead of the anti-blast and noise-proof ship superstructure includes an impact-resistant structure and two sandwich panels 3 for noise reduction, The two noise-reducing sandwich panels 3 are respectively fixedly connected to the upper end of the impact-resistant structure and the lower end of the impact-resistant structure. The impact-resistant structure includes an upper steel plate 201 above and a lower steel plate 202 below, wherein the bottom surface of the upper steel plate 201 is provided with more than two upper grooves 203, and the upper surface of the lower steel plate 202 is also provided with more than two grooves. The lower groove 204, the projection of the upper groove 203 in the vertical direction and the projection of the lower groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com