Drum washing machine provided with damping counterweights

The technology of a drum washing machine and a counterweight is applied to other washing machines, washing devices, textiles and paper making, etc., which can solve the problems of high cost, unsatisfactory vibration and noise reduction effect, etc., and achieve the effect of ensuring sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

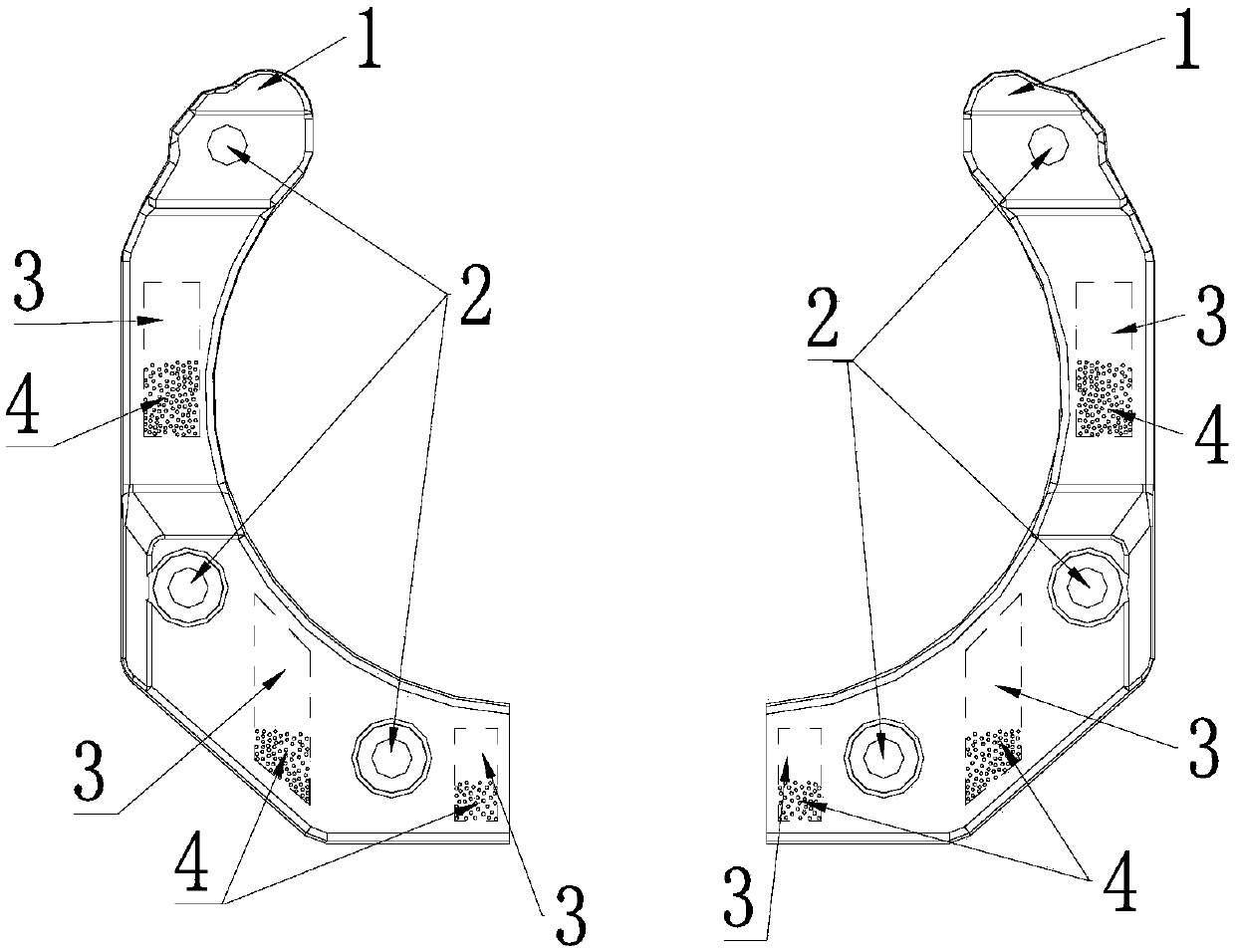

[0050] Such as Figure 1-Figure 3 As shown, the embodiment of the present invention introduces a damping counterweight. The counterweight 1 is provided with at least one hollow chamber 3 , and at least one mounting hole 2 is provided through the upper end and the lower end of the counterweight 1 respectively. The hollow chamber is filled with a certain volume of damping particles, and the fastener fastens the counterweight to the outer cylinder of the washing machine through the installation hole.

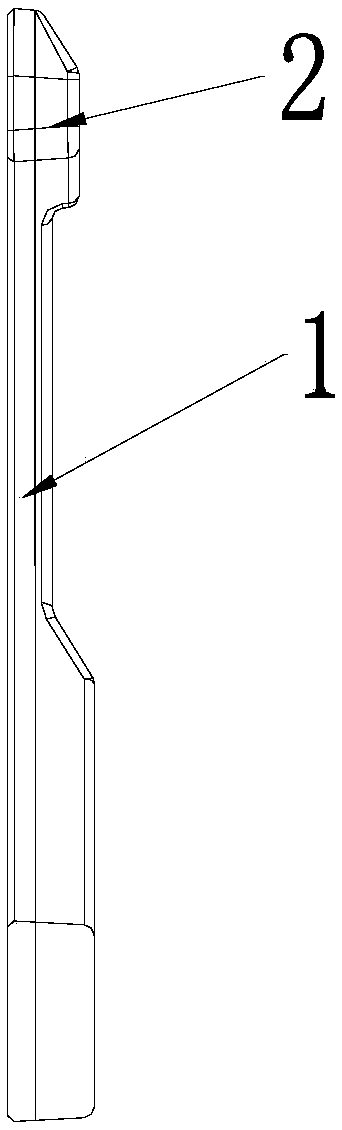

[0051] In this embodiment, the counterweight 1 is an arc-shaped flat sheet structure extending vertically, the inner side of the counterweight 1 is a regular semicircle, and the upper and lower ends of the counterweight 1 have the same thickness. The part is lower than both ends; when the counterweight 1 is fixedly installed on the outside of the outer cylinder 5 of the washing machine through fasteners, the inner side of the counterweight 1 can fit well with the outer side of the ...

Embodiment 2

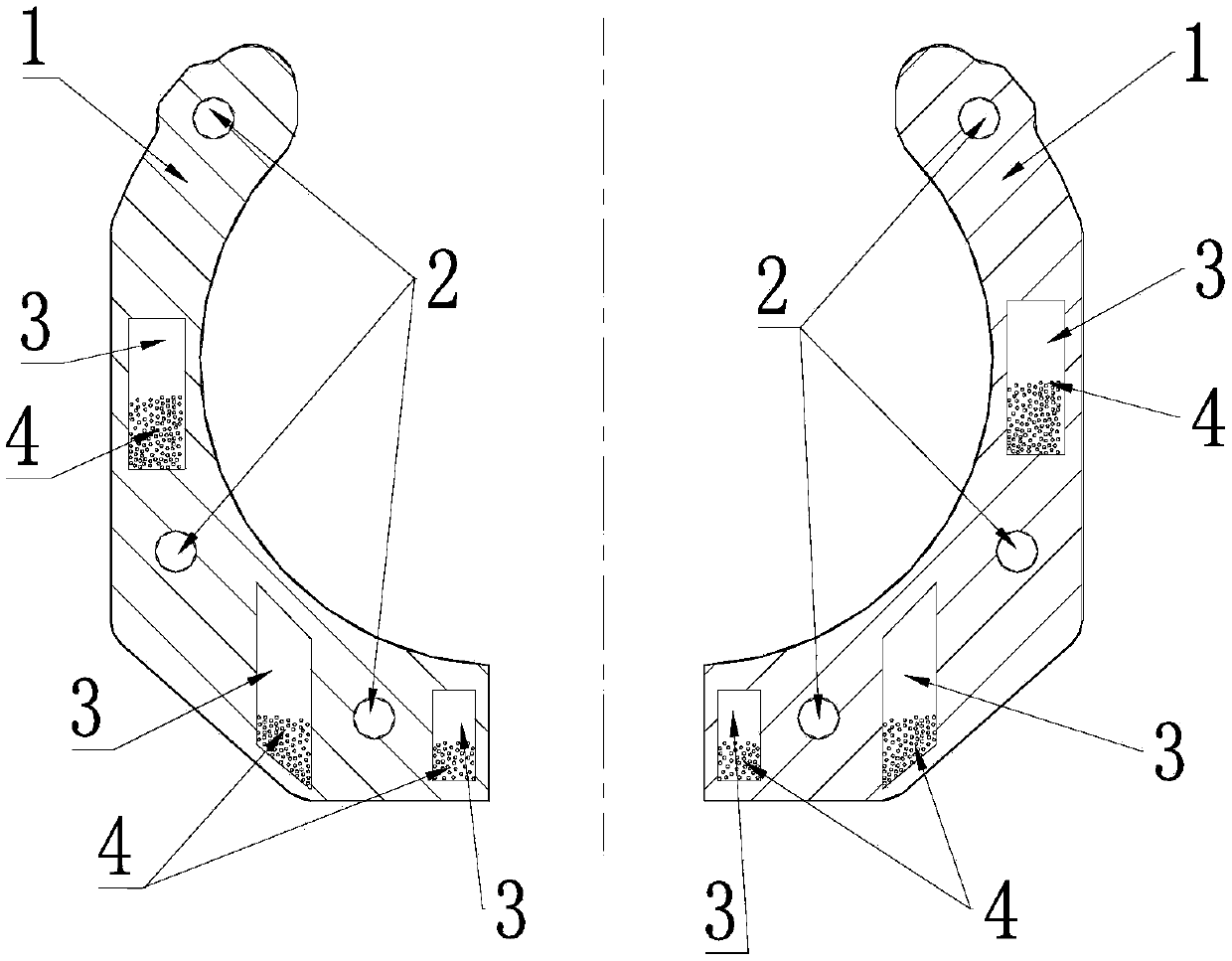

[0058] Such as Figure 4-Figure 5 As shown, a layer of shell 6 is arranged outside the counterweight 1, and the shell 6 completely covers the entire counterweight 1. At the same time, there is a gap between the inner surface of the shell 6 and the outer surface of the counterweight, that is to say, the counterweight The gap between the outer surface of the weight 1 and the inner side of the casing 6 constitutes a hollow chamber, and a certain amount of damping particles 4 are filled in the hollow chamber formed by the gap. During the working process of the washing machine, the inner surface of the casing 6 and the The damping particles 4 between the outer surfaces of the counterweight 1 will also vibrate, and collisions will occur between the damping particles, between the damping particles and the end face of the counterweight and the inner wall of the housing, and consume the washing machine together with the damping particles in the hollow chamber. The kinetic energy genera...

Embodiment 3

[0065] Such as Figure 6 As shown, in the embodiment of the present invention, the outer surface of the counterweight 1 is provided with at least one concave groove inwardly, and the outer wrapping of the counterweight is fixed with a casing, and the casing at least seals and covers the opening of the groove, so that The housing 6 seals the groove that covers the opening to form a hollow chamber 3, and the hollow chamber formed by the groove is filled with damping particles 4; at the same time, the hollow chamber 3 formed by the groove does not communicate with the adjacent installation hole 2, and the hollow chamber 3 is hollow. There is a certain distance between the four walls of the chamber 3 and the inner side wall of the adjacent mounting hole 2 or the outer surface of the counterweight 1, and there is also a certain distance between the bottom of the hollow chamber 3 and the bottom surface of the counterweight 1, and the upper part of the hollow chamber 3 The end face i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com