Generalized photonic crystal acoustic shield

A technology of phononic crystal and sound insulation cover, which is applied in the field of generalized phononic crystal sound insulation cover, can solve the problems of bulky structure of sound insulation cover, can not meet the requirements, small sound insulation volume, etc. Low cost and high sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

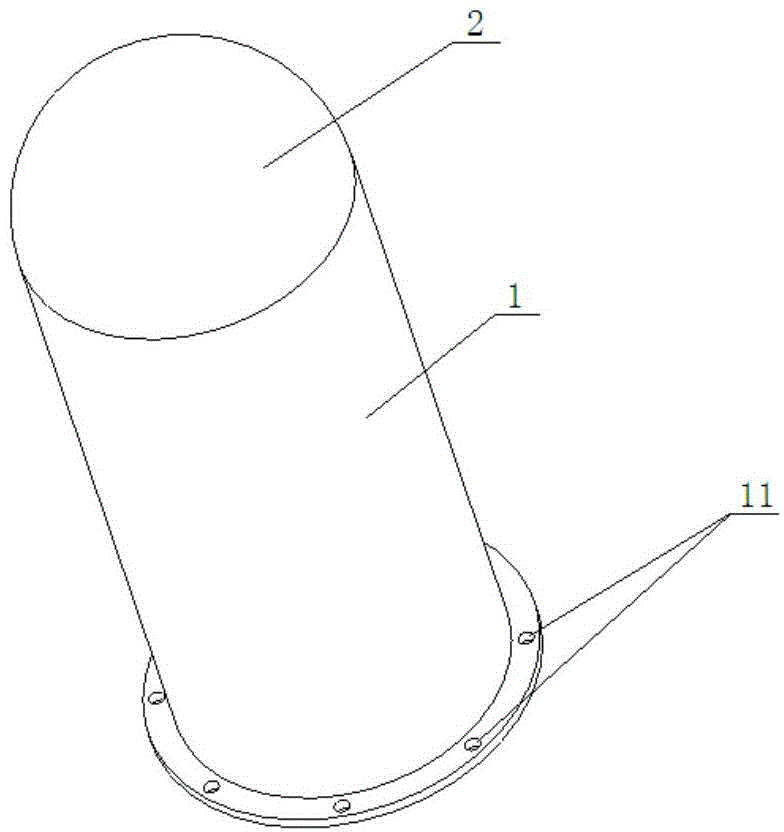

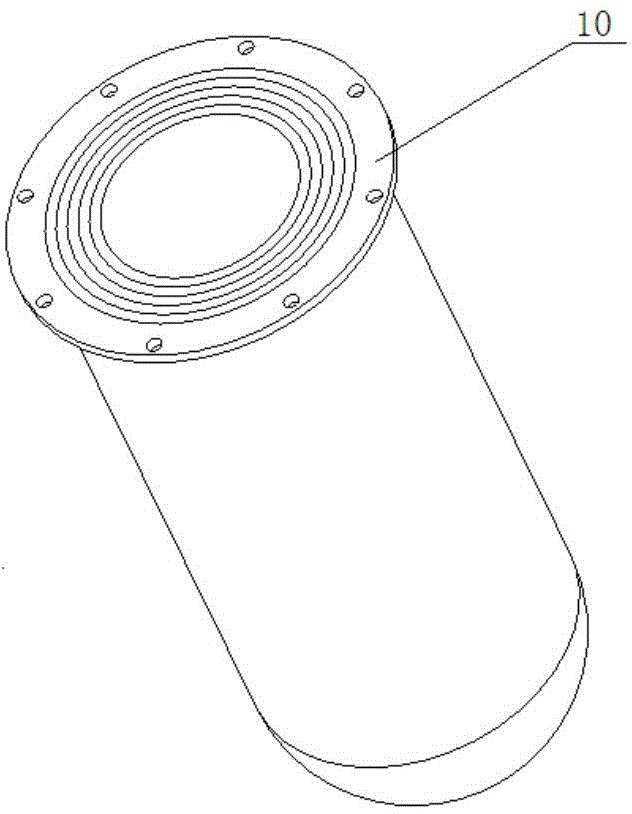

[0017] Implementation Case 1: Combining figure 1 , figure 2 with image 3 , the present invention includes a generalized phononic crystal cylindrical shell 1 and a generalized phononic crystal hemispherical shell 2 connected to the generalized phononic crystal cylindrical shell 1, and a circular boss 10 is arranged at the bottom end of the generalized phononic crystal cylindrical shell 1, The annular boss 10 is provided with threaded hole 11 along the circumferential direction, and the annular boss 10 is connected with the base, that is, the present invention is connected with the base by the connection mode of bolt connection, and the present invention can also be connected with the machine. frame or foundation connection, the generalized phononic crystal cylindrical shell and the generalized phononic crystal hemispherical shell are provided with at least two periodic components from the inside to the outside, and each periodic component is a non-metallic layer and a metal ...

Embodiment example 2

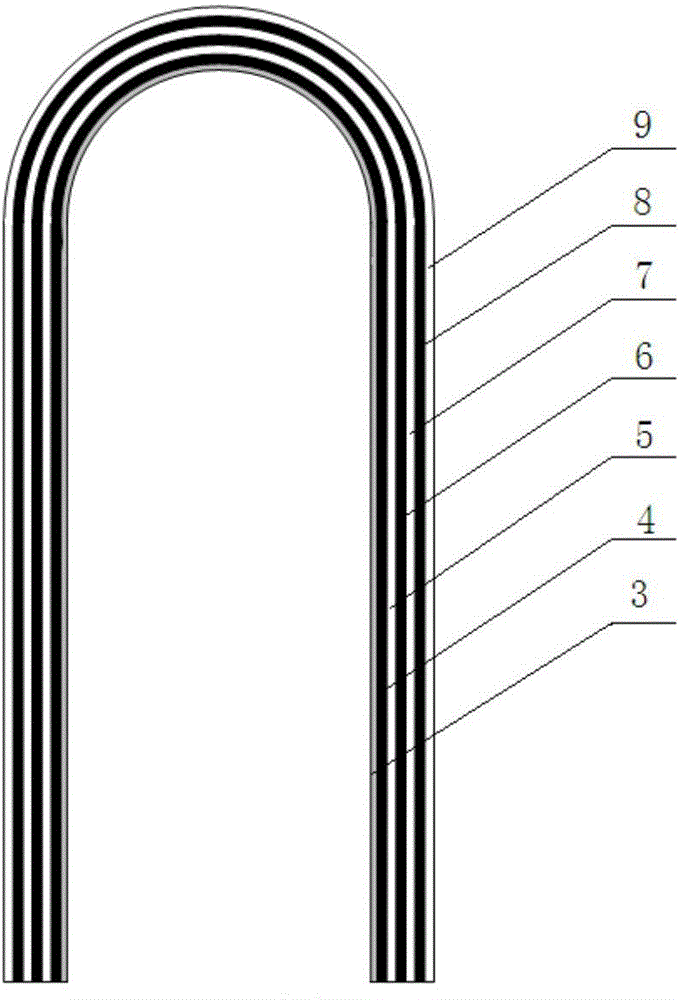

[0018] Implementation case 2: Based on the above implementation cases, combined with image 3 , the present invention is provided with three periodic components, the generalized phononic crystal cylindrical shell and the generalized phononic crystal hemispherical shell are the first non-metallic layer 4, the first metal layer 5, and the second non-metallic layer 6 from the inside to the outside. , the second metal layer 7, the third non-metal layer 8 and the third metal layer 9, each layer is attached to each other, that is, three layers of non-metal shells 4, 6, 8 and three layers of metal shells 5, 7, 9 The three-period generalized phonon crystal structure is formed by connecting together through swelling, adhesion or other reasonable process methods.

Embodiment example 3

[0019] Implementation case three: Based on the above implementation cases, combined with image 3 , the inner surface of the generalized phononic crystal cylindrical shell and the generalized phononic crystal hemispherical shell of the present invention is evenly coated with sound-absorbing material 3, and the evenly coated sound-absorbing material 3 can further improve the sound insulation of the sound insulation cover of the present invention performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com