Slideway blade system for vertical wind turbines

A wind power generator and slideway technology, applied to wind power generators, wind power generators at right angles to the wind direction, engines, etc., can solve the problem of large start-up dead angle and reversing dead angle, small wind-receiving area of airfoil blades, and wind utilization Low efficiency and other issues, to achieve the effect of good balance characteristics, high wind utilization rate, increased stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

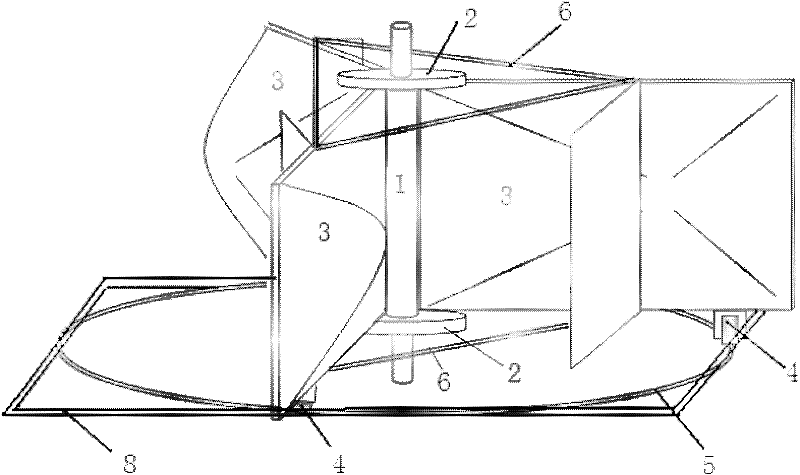

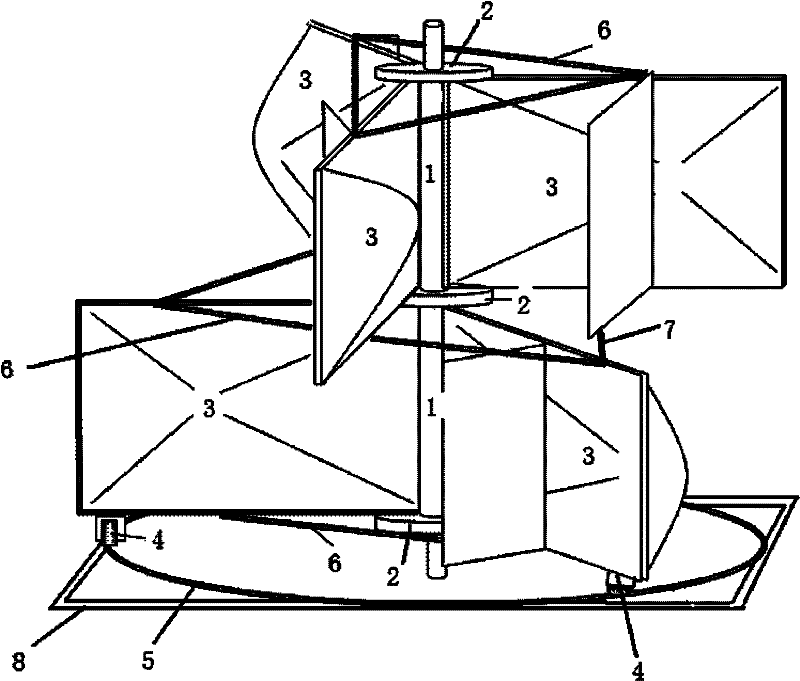

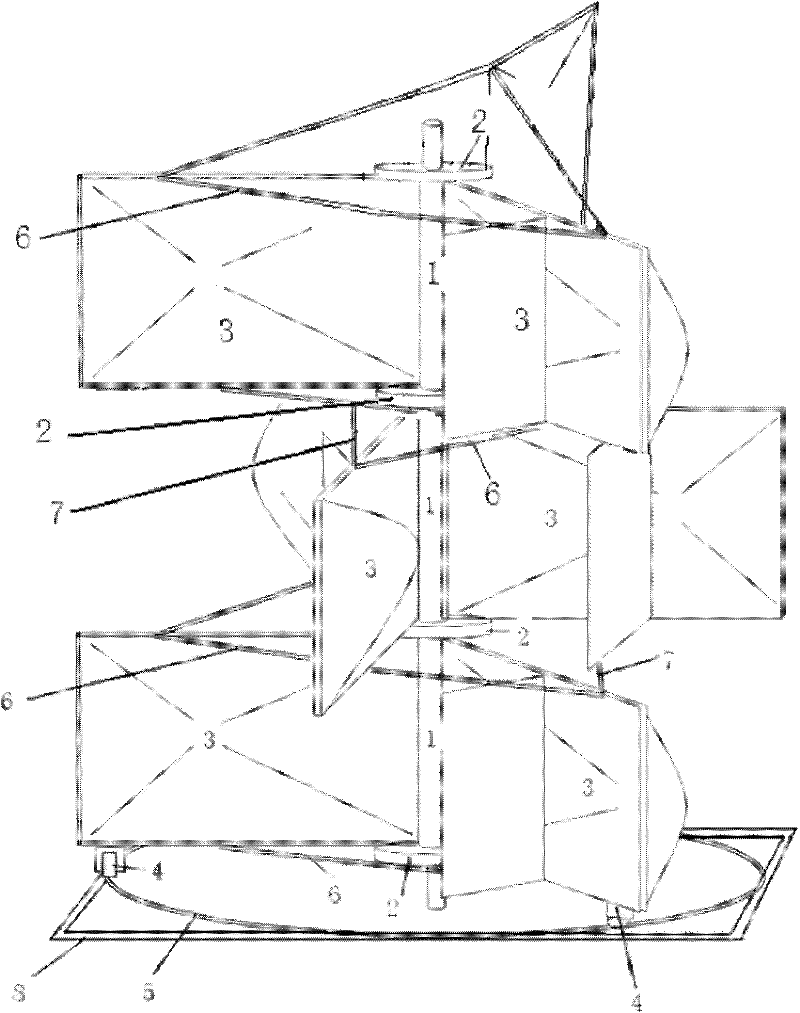

[0022] Specific implementation mode one: combine figure 1 and Figure 4 To illustrate this embodiment, the slideway-type fan blade system of the vertical wind power generator in this embodiment is a single-layer fan blade system, and the single-layer fan blade system includes a compound shaft 1, two shaft fan blade connection methods Blue plate 2, three single fan blades 3, three fan blade pulleys 4, fan blade annular slideway 5 and two triangular fan blade fixing frames 6, the two machine shaft fan blades are connected to the flange 2 installed on On the composite machine shaft 1, three single fan blades 3 are connected between the connecting flanges 2 of the two machine shaft fan blades, and the three single fan blades 3 surround the composite machine shaft 1 in a ring, The three single blades 3 are arranged at an angle of 120 degrees, the upper ends of the three single blades 3 are fixedly connected by a triangular blade fixing frame 6, and the lower ends of the three sing...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination figure 1 , Figure 4 to Figure 6Describe this embodiment, the single fan blade 3 of this embodiment includes a refraction wind deflector 3-2, a fan blade frame 3-3, a fan blade body 3-4, two support frames 3-5 and two fan blades Shaft fixing part 3-1, fan blade body 3-4 is composed of shell and internal skeleton welded as a whole, the outer contour line of the outer shell cross section of fan blade body 3-4 is a convex arched curve, and the fan blade body The outer contour of the longitudinal section of the shell of 3-4 is a wing streamline curve, the fan blade frame 3-3 is welded on the plane of the fan blade body 3-4, and the fan blade frame 3-3 and the compound shaft 1 are close to one end A fan shaft fixing part 3-1 is installed on the upper and lower sides of the upper and lower sides respectively, and the single fan blade 3 establishes a mechanical connection with the shaft fan connecting flange 2 through the fan shaf...

specific Embodiment approach 3

[0024] Specific implementation mode three: combination Figure 4 To illustrate this embodiment, the internal skeleton of the fan blade body 3-4 in this embodiment is a steel belt mesh skeleton or a steel wire mesh skeleton, and the outer shell of the fan blade body 3-4 is made of glass fiber reinforced plastic or carbon fiber. With such setting, the surface is smooth and the wind resistance is small. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com