Automatic straight pipe flange welding machine

A technology of flange welding and straight pipe, applied in the direction of welding equipment, welding accessories, welding rod characteristics, etc., can solve the problem of low welding difficulty, achieve the effects of easy disassembly, stable rotation, and high welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

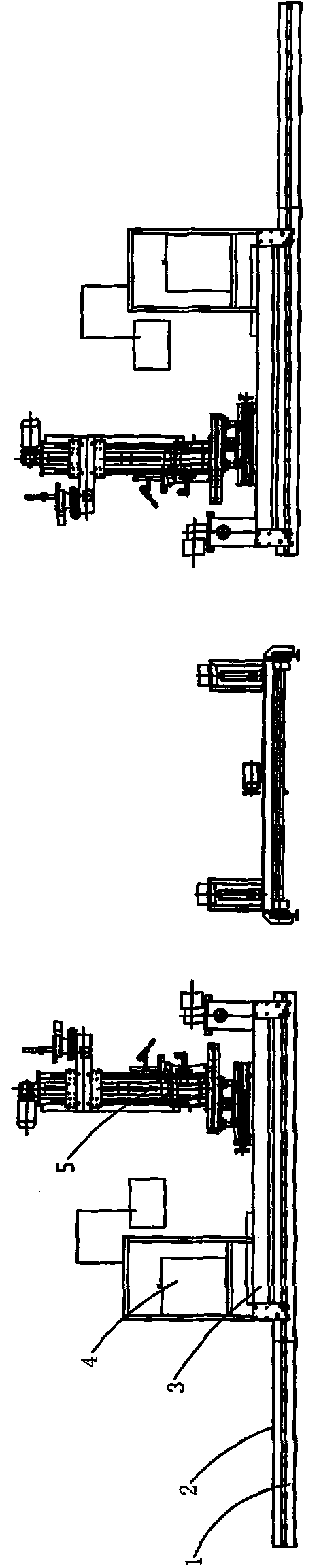

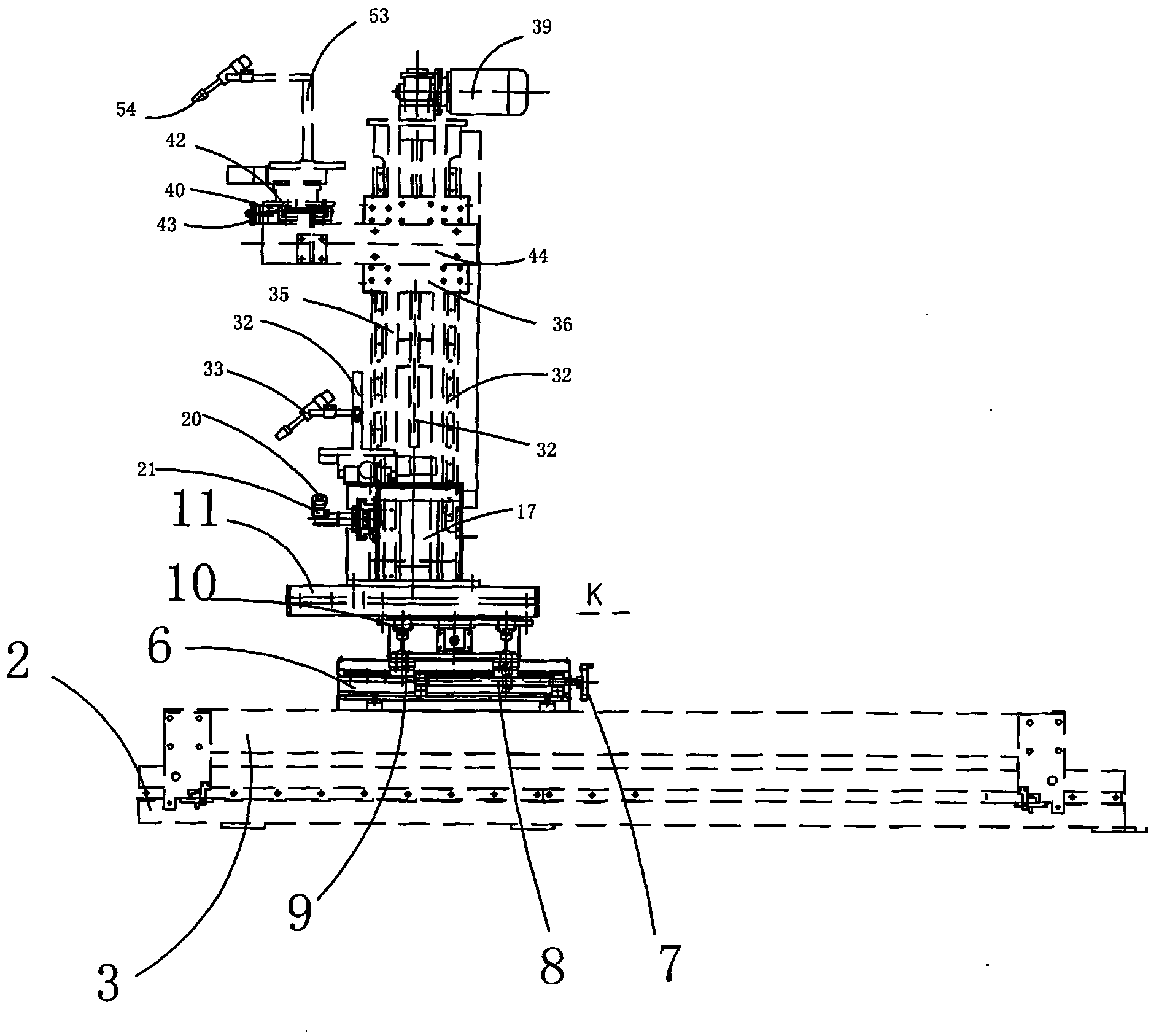

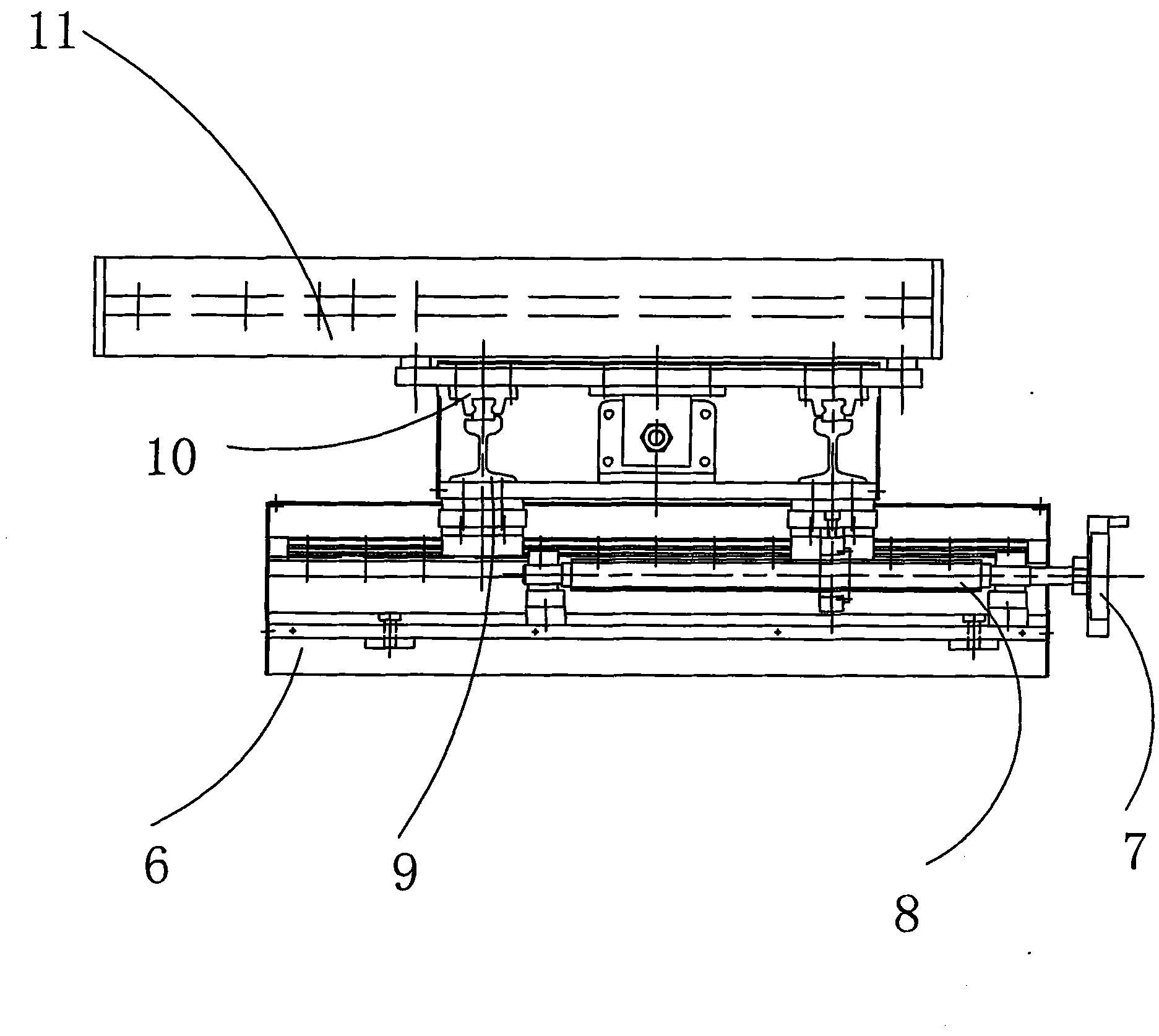

[0036] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 As shown, an automatic straight pipe flange welding machine includes a base 1, the base 1 is provided with a base guide rail 2, the base guide rail 2 is provided with a trolley base 3, and one side of the trolley base 3 is provided with Control system 4, the trolley base 3 is provided with a welding torch machine 5, the welding torch machine includes a longitudinal adjustment mechanism, a horizontal adjustment mechanism, an inner welding torch mechanism, an outer welding torch mechanism, and a roller adjustment mechanism, and the inner welding torch mechanism Including the inner welding gun column device and the inner welding torch device, the outer welding torch mechanism includes the outer welding torch column device and the outer welding torch device, and the longitudinal adjustment mechanism inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com