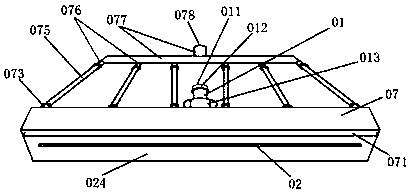

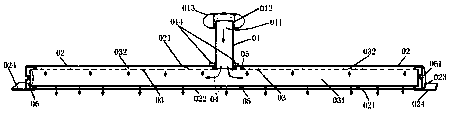

Ceiling face and wall face putty scraping device with automatic supplying and residual slurry automatic recovery functions

An automatic recycling and automatic feeding technology, which is applied in the direction of construction and building construction, can solve the problems of long grinding and leveling, slow construction progress, more labor and time investment, etc., so as to save time and manpower and reduce grinding Time, the effect of reducing technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

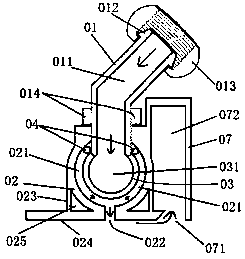

Embodiment 1

[0024] The device of the present invention is connected to the putty feeding device before working, or connected to a hard tube of a wiper rod and then connected to the feeding device. When working, the putty slurry enters the inner cavity slurry guide tube 03 from the feed inlet 011 The cavity 031 moves to its two ends, and then flows into the space gap of the outer cavity 021 through the inner and outer cavity channel holes 032 or the inner and outer cavity channel gaps, and is divided into two corresponding directions through the two-way extrusion of the narrow space of the outer cavity 021. After being distributed, the two are combined into one, and the thickness is uniformly extruded from the discharge gap 022 to the exit of the discharge gap 022, and then the putty slurry is wiped along the ceiling or wall through the long and straight scraper 024 The material is spread more evenly and evenly and scraped to the job; when constructing on the ceiling surface or the wall high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com