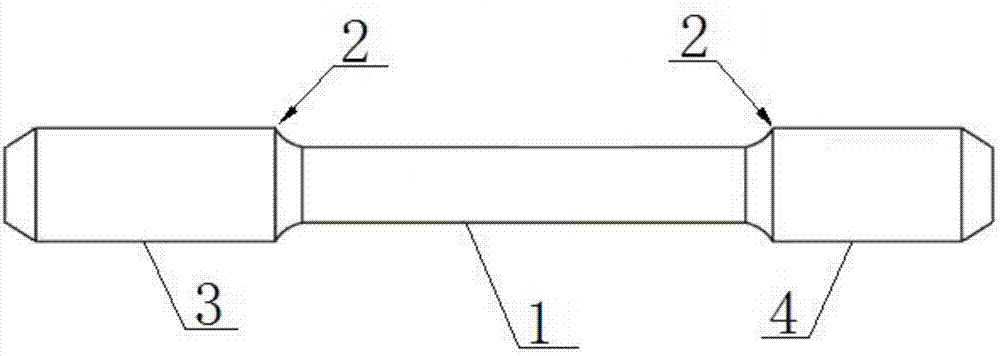

Double-end toothed stud and manufacturing method thereof

The technology of a stud and a stud body is applied in the field of preparing a double-ended stud and double-ended stud, which can solve the problem that burrs and double-ended stud threads are easily generated at the joint of the thread pattern and the chamfering of the thin rod. The problem is that the matching degree of the segment is not high, the matching degree of the thread segment and the stud body is not high, etc., so as to reduce the product logistics cycle, control the brittleness of the product, and reduce the deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] The ZA28-40 thread rolling machine was purchased from Qingdao Shengjian Machinery Factory in Shandong Province;

[0048] 34CrNiMo6 bars were purchased from Hubei Daye Special Steel Co., Ltd.;

[0049] High-speed quenching oil was purchased from Dongguan Meike Petrochemical Co., Ltd.

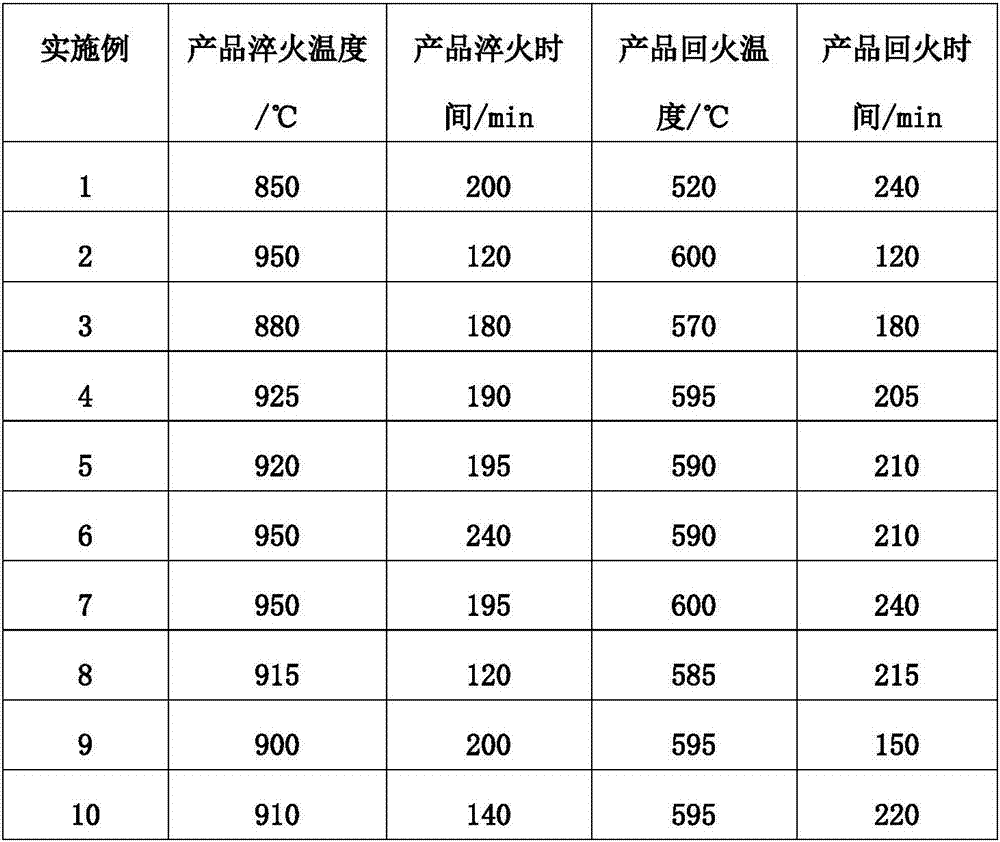

[0050] Ten groups of different heat treatment conditions were selected for heat treatment of rough car products. The specific heat treatment parameters of each group are shown in Table 1:

[0051] The heat treatment parameter of table 1 embodiment

[0052]

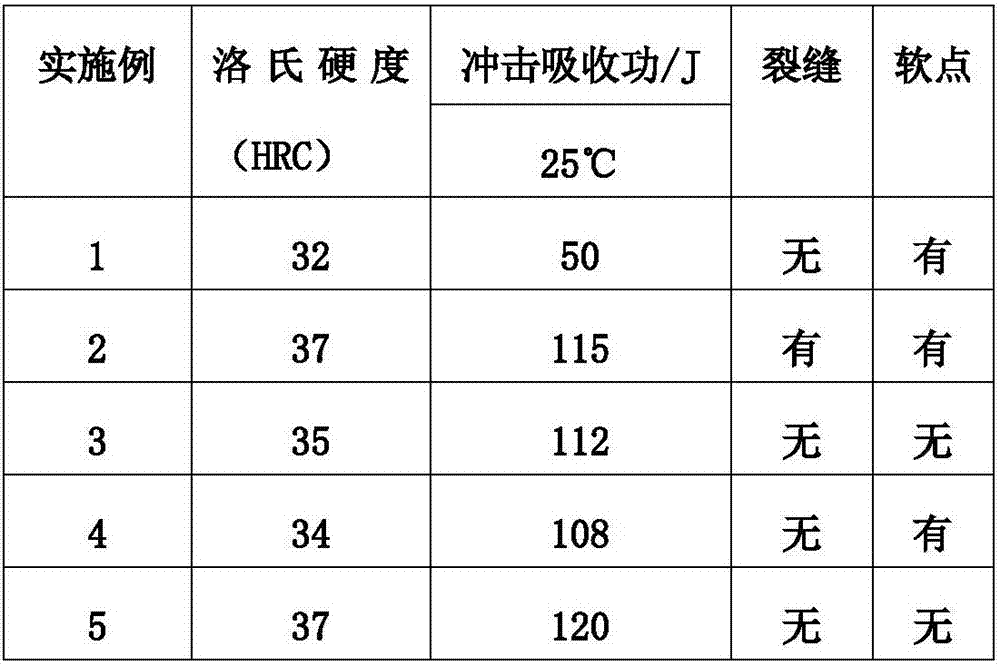

[0053] Adopt ten groups of embodiment heat treatment parameters to process the embodiment samples, the mechanical properties and physical properties of the double-headed studs finally processed into ten groups of embodiments are as shown in Table 2:

[0054] The mechanical performance and the physical performance of the double-ended tooth stud that the embodiment of table 2 is finally processed into

[0055]

[0056]

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com