Tape feeder

A technology of feeder and top belt, which is applied in the field of belt feeder and can solve the problem of not being able to prevent parts from flying out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, an example which actualizes the preferred mode for carrying out the present invention will be described.

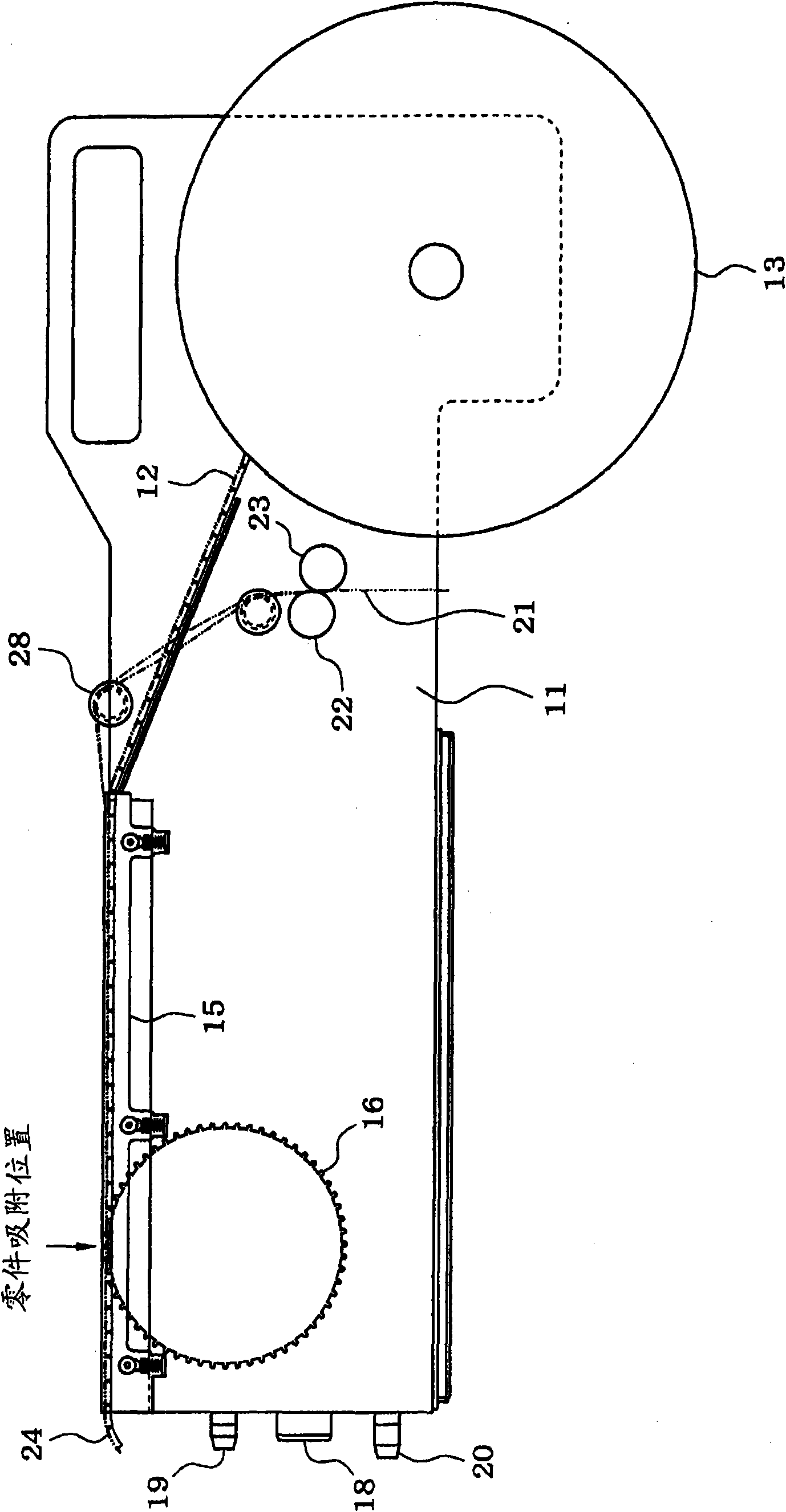

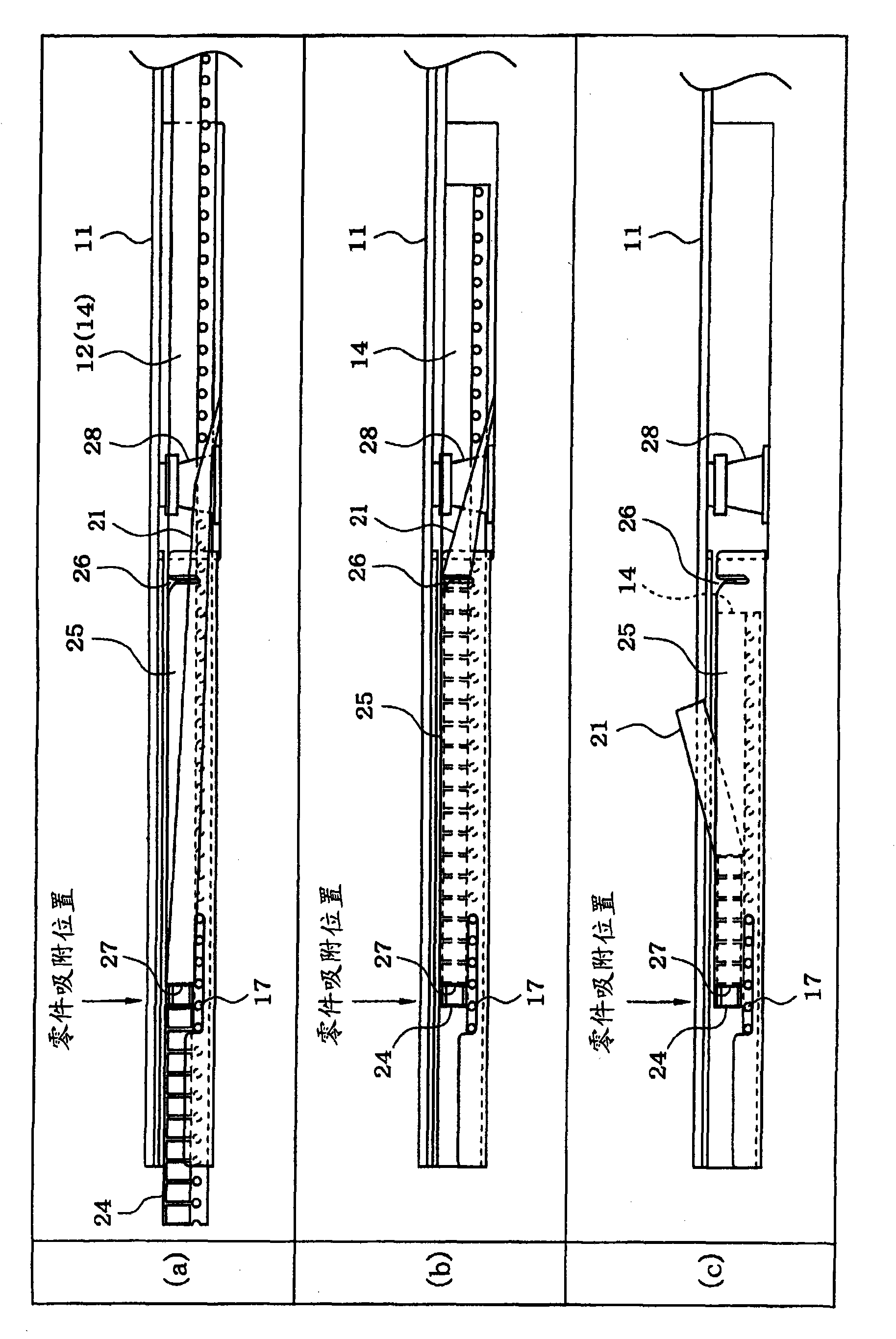

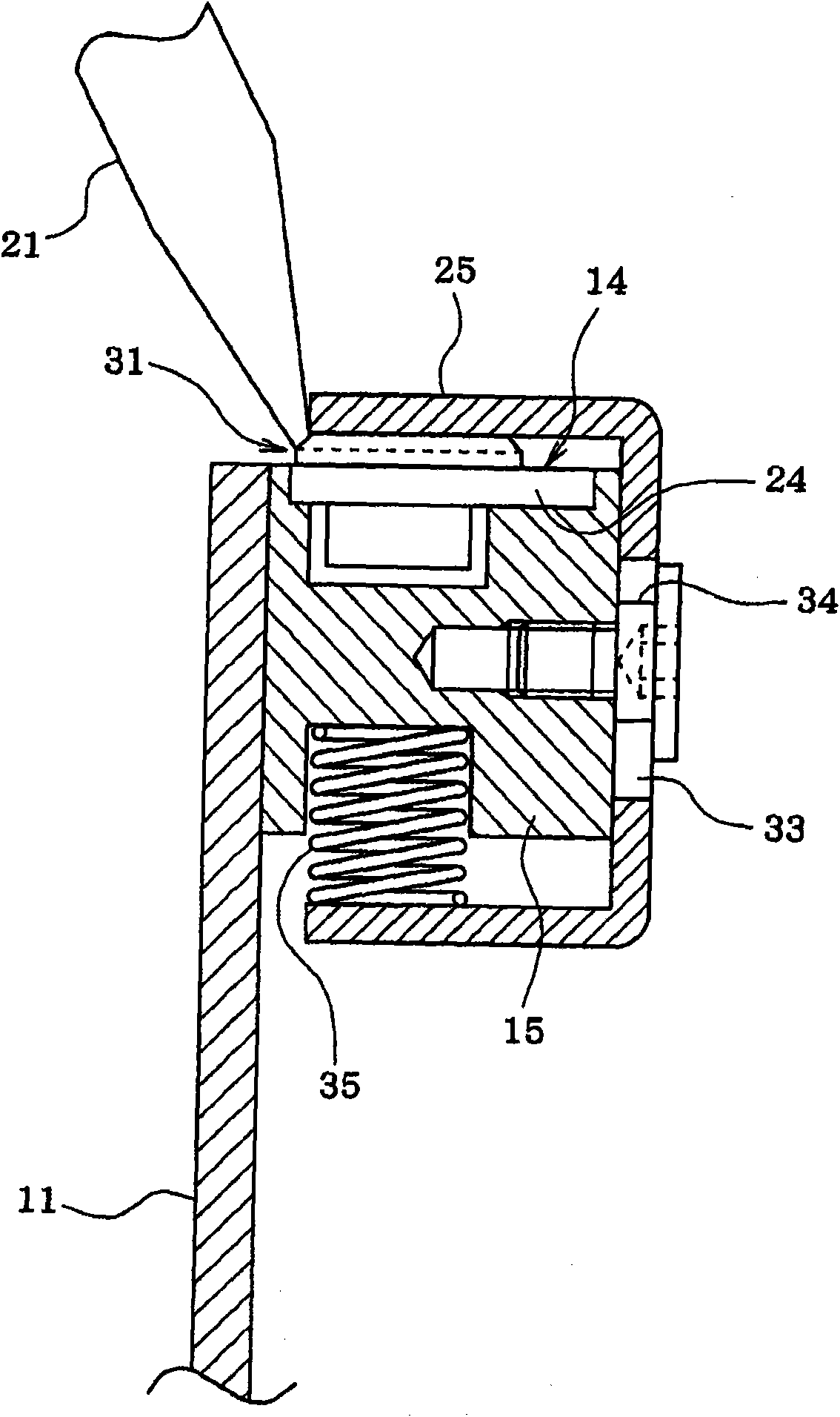

[0023] First, based on Figure 1 to Figure 3 The structure of the tape feeder will be described.

[0024] On the front end side of the feeder body 11 of the tape feeder ( figure 1 In the right side of the figure), a tape roll 13 around which the parts packaging tape 12 is wound is detachably provided. When using the short tape 14 (parts packaging tape after cutting), it is used in a state where the tape roll 13 is removed from the feeder main body 11 .

[0025] Attached to the upper surface of the feeder body 11 is a tape guide member 15 forming a tape path for guiding the parts packaging tape 12 or the short tape 14 pulled out from the tape roll 13 to the parts suction position. Inside the feeder body 11 ( figure 1 The left side in the middle), a toothed reel 16 (stepping conveying mechanism part) for stepping and conveying the parts packaging bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com