Tunnel ring direction drainpipe equipped with strip heat-insulating layer

A drainage pipe and thermal insulation layer technology, which is applied in drainage, mining equipment, safety devices, etc., can solve the problems of peeling and peeling of the thermal insulation layer, failure to pay attention to the waterproof and moisture-proof of the thermal insulation layer, and high project cost, so as to achieve short distance of seepage and good drainage Outstanding effect, good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

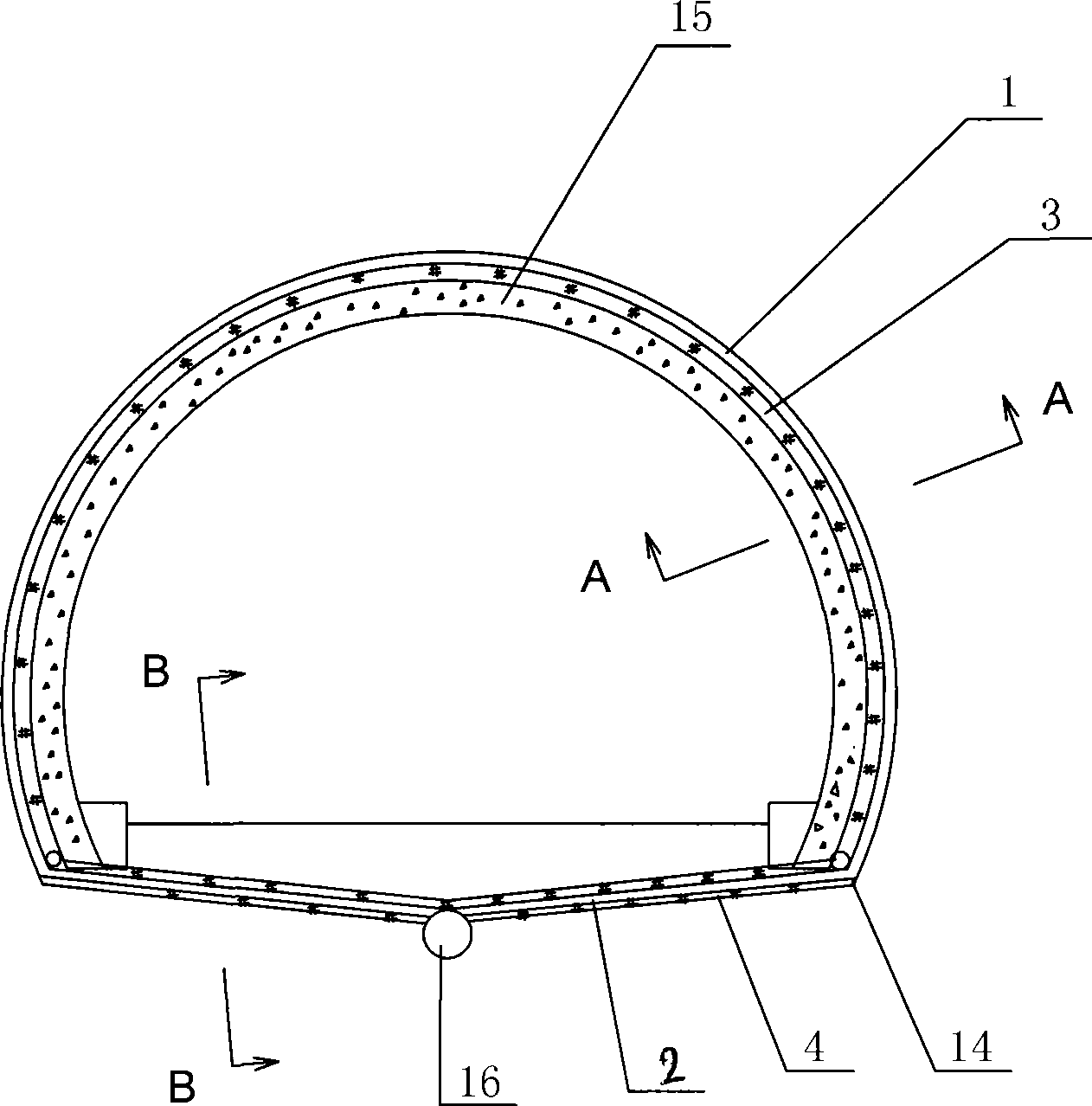

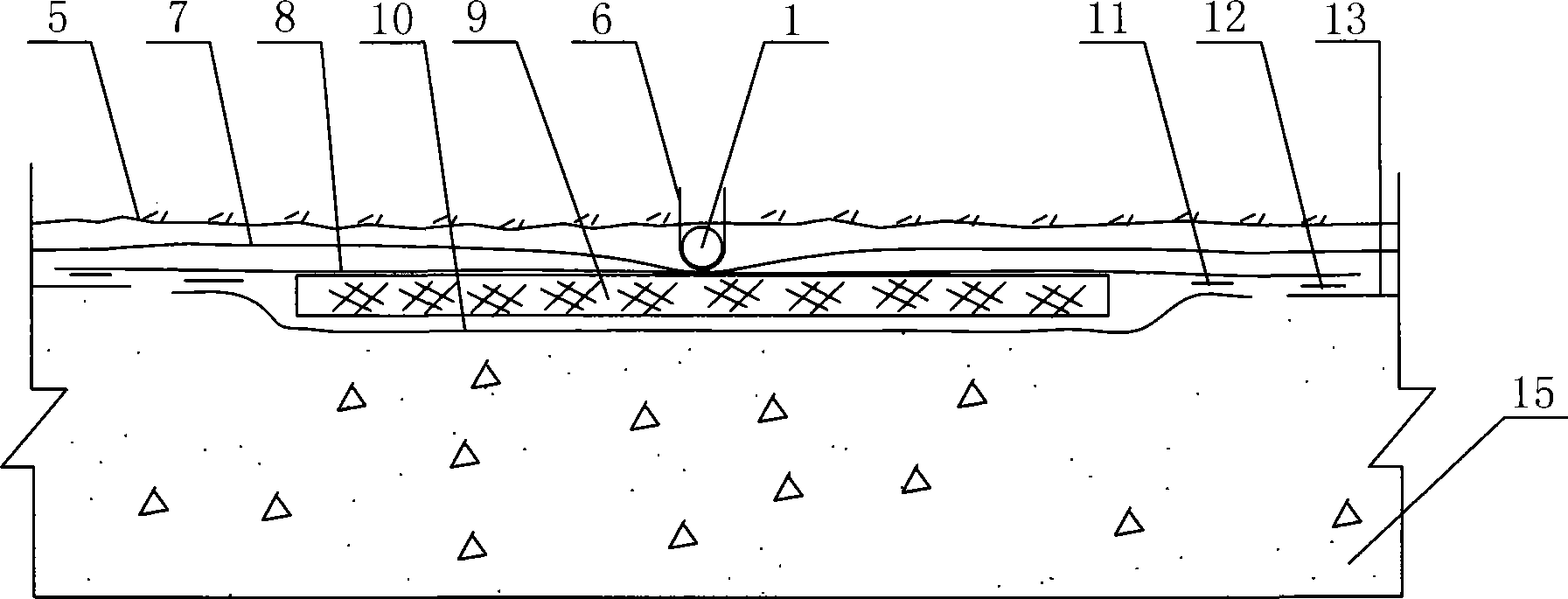

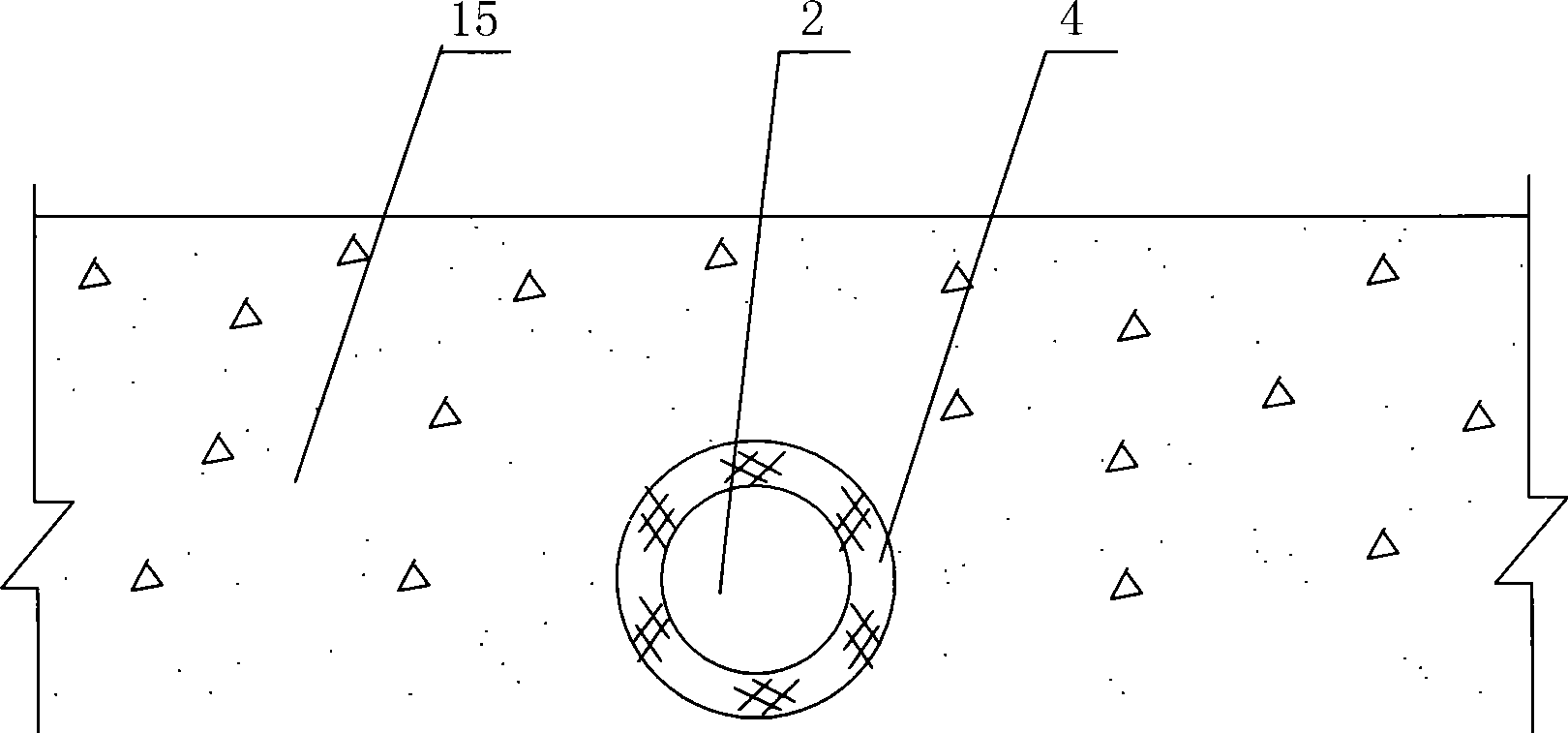

[0021] Such as figure 1 , figure 2 with image 3 As shown, the present invention includes a lining wall rear circumferential drainage pipe 1 and two road-surface circumferential drainage pipes 2 correspondingly connected to its two ends, wherein the lining wall rear circumferential drainage pipe 1 is a water-permeable pipe, and the two road surface circumferential drainage pipes The drainpipe 2 is arranged transversely under the tunnel road surface, and communicates with the circumferential drainpipe 1 behind the lining wall and the central drainpipe 16 located in the center of the tunnel. In use, the seepage water from the formation behind the lining wall of the tunnel enters the circumferential drainage pipe 1 behind the lining wall, and is directly discharged from the central drainage pipe 16 through the circumferential drainage pipes 2 under the two road surfaces. In order to prevent the circumferential drainage pipe 1 behind the lining wall from being frozen in the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com