Pressure torsion test loading device for steel tube concrete pile

A technology of concrete-filled steel tube columns and loading devices, which is applied in the direction of measuring devices, testing of mechanical components, and testing of machine/structural components, etc., can solve problems such as inconstant torque variation and affecting the rotation of concrete-filled steel tube columns, and achieve good conformity, The effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

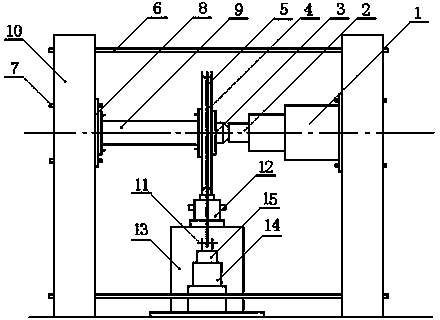

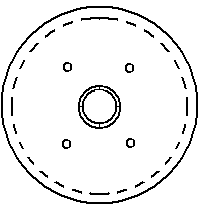

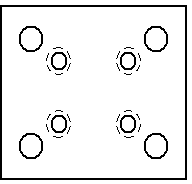

[0011] Two reaction piers 10 are installed on the ground according to the distance required for the test, and the tie rods 6 pass through the four corners of the reaction piers 10 and are locked to connect the two reaction piers 10 to increase its resistance to horizontal reaction. ability to force. The pressure jack 1 is installed on the reaction pier 10 on one side, the front end of the pressure jack 1 is equipped with a pressure sensor 2 and a pressure bearing 3, the tension jack 14 for applying torque is installed between the reaction pier 10, and the top of the tension jack 14 A tension sensor 15 is installed, and the tension sensor 15 is connected to the wire rope 5 wound on the grooved disc 4 through the connector 11, and the pedestal 13 on which the roller support 12 is installed is installed under the grooved disc 4 to support Grooved disc4. When carrying out the test, one end of the steel tube concrete column 9 is installed on the reaction pier 10 on one side throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com