Test device and test method for measuring mechanical properties of lap joint samples

A test device and performance technology, applied in the direction of measuring device, using stable bending force to test material strength, using stable shear force to test material strength, etc., can solve the limitation of test accuracy, complicated operation method, difficult to realize, etc. problems, achieve the effect of reducing fixture cost, improving test efficiency and simplifying operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The device of the present invention is further described below in conjunction with examples: the present embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following examples .

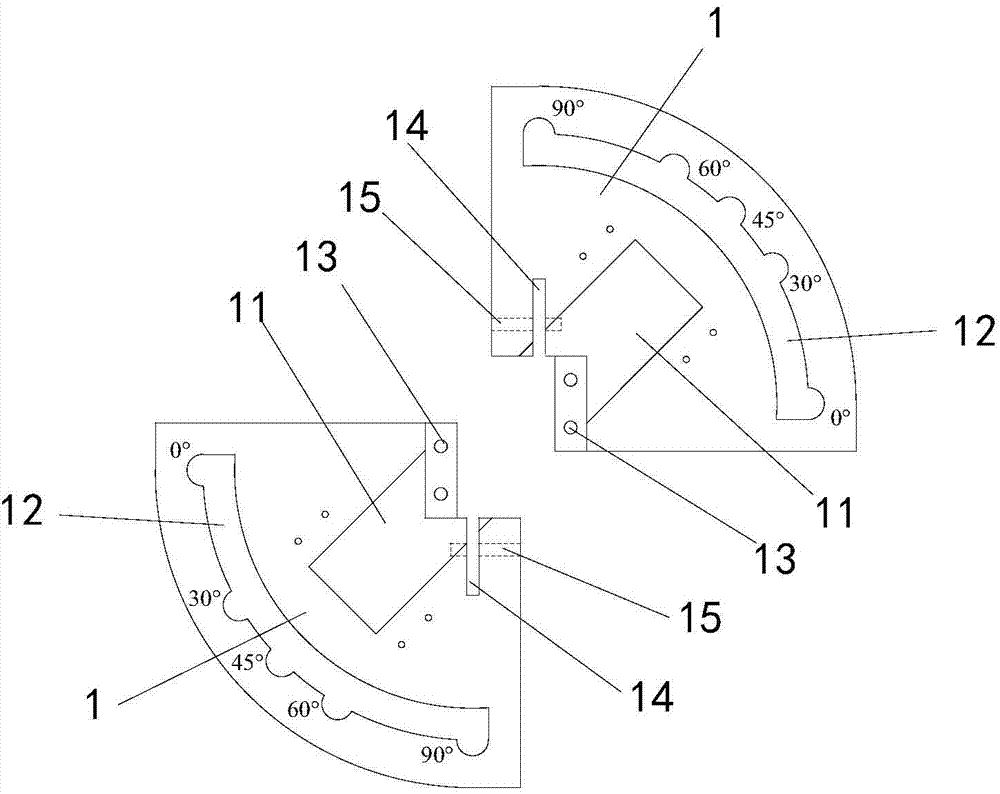

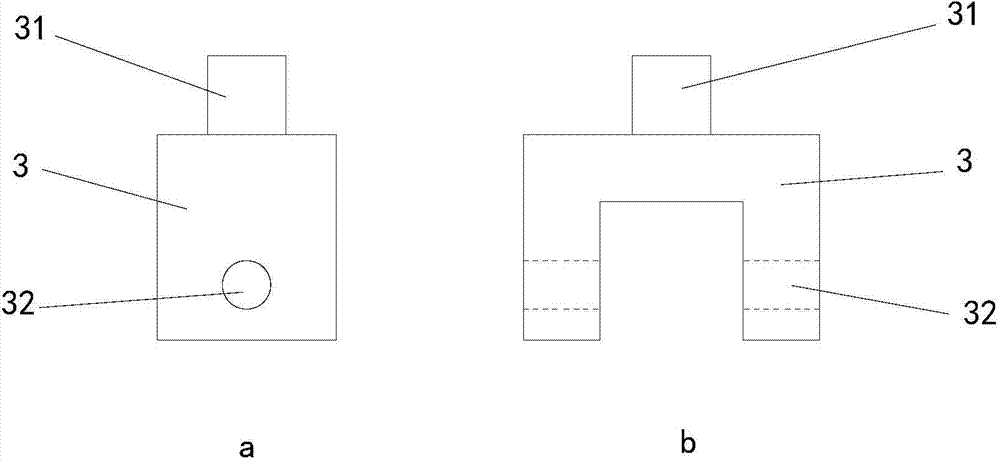

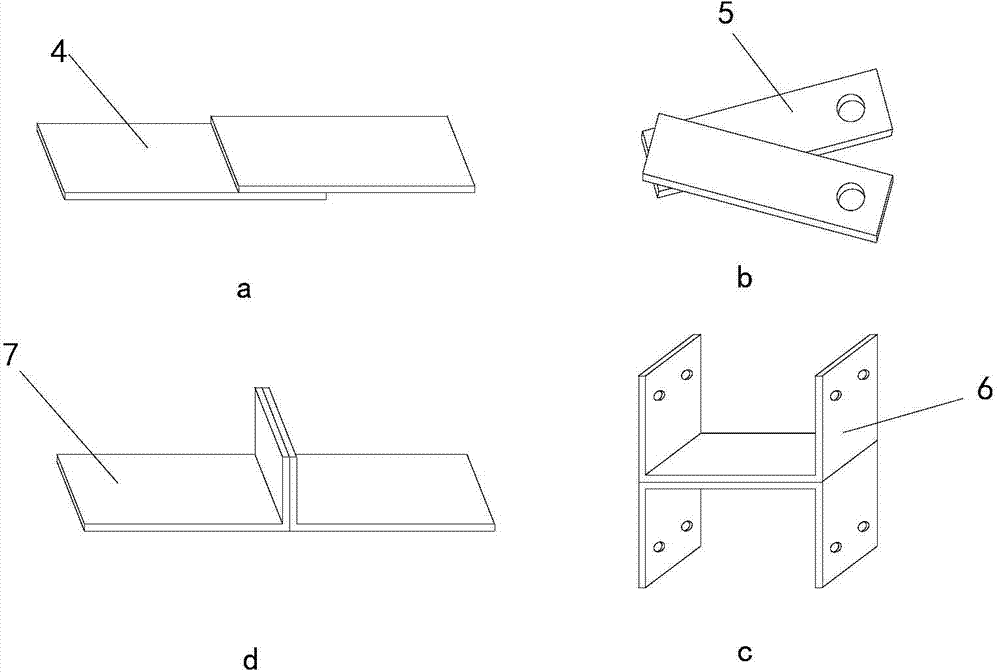

[0026] Such as Figure 1~5 As shown, the present invention is used to measure the test device of the mechanical properties of lapped samples, which is used to be connected to the experimental equipment to measure the mechanical properties of lapped samples, which includes two clamps 1, two cover plates 2, two A loading head 3 and four lap joint samples 4, 5, 6, 7.

[0027] Two clamps 1 are used in combination to clamp the lapped specimen. The two clamps have the same symmetrical structure. The main body is fan-shaped. There is a rectangular wide groove 11 on the fan-shaped surface, and an arc adjustment gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com