High pressure torsion test method capable of fining sample grain

A technology of high-pressure torsion and experimental methods, applied in the preparation of test samples, etc., can solve difficult problems, achieve the effect of reducing requirements and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

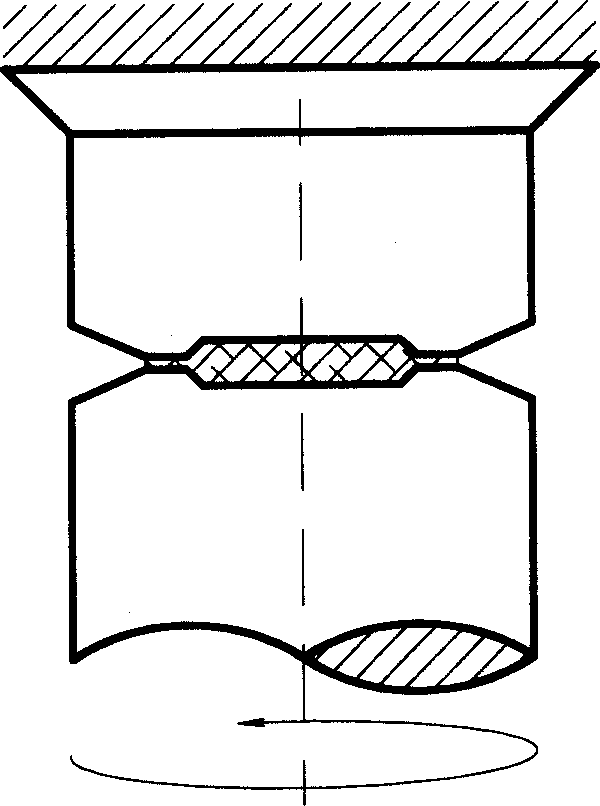

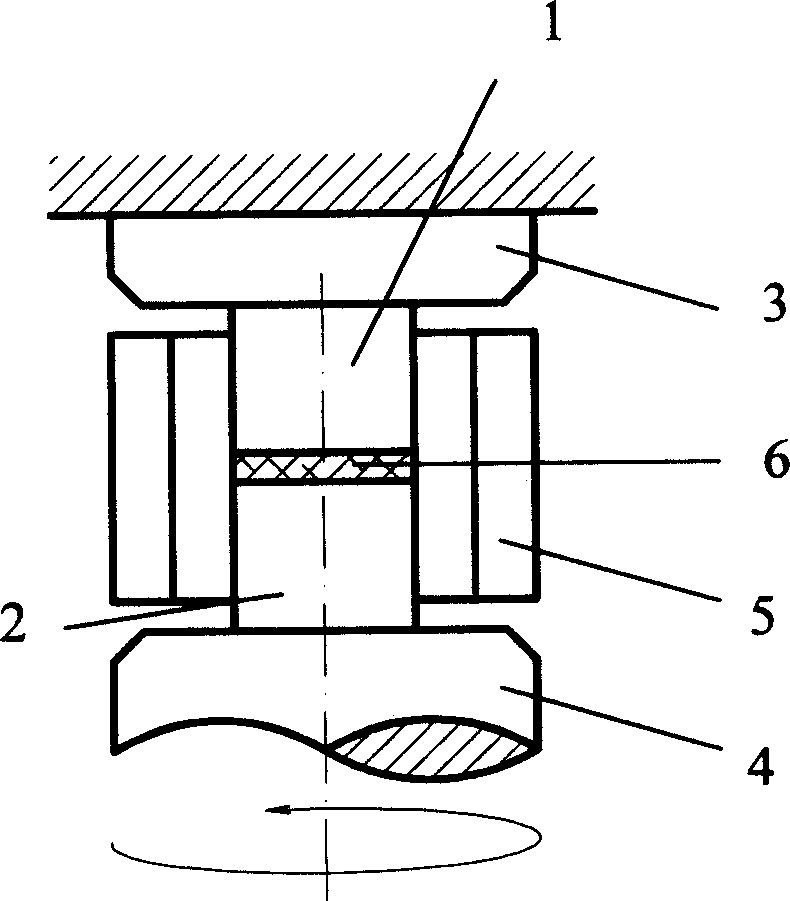

[0018] figure 2 It is a structural schematic diagram of the test device adopted in the present invention. Concrete steps of the present invention are as follows:

[0019] 1) Install cylindrical upper and lower anvils 1 and 2 on the upper and lower pressing heads 3 and 4 of the press respectively, and a thrust bearing is also installed between the lower anvil 2 and the lower pressing head 4, through which the lower The anvil head 2 can rotate axially, and the ends of the upper and lower anvil heads 1 and 2 are textured;

[0020] 2) The upper and lower anvils 1 and 2 are fitted with side rings 5. The side rings 5 are double-layered structures inside and outside. The inner layer is made of ASSAB88 tool steel, which has high hardness and toughness. The outer layer is made of medium carbon. Steel has high toughness, and the side ring 5 fits with the upper and lower anvil heads 1 and 2 with zero clearance;

[0021] 3) The sample 6 to be processed is placed in the side ring 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com