Precision material micro mechanical property in-situ torsion testing platform

A technology of micro-mechanics and torsion testing, which is applied in the fields of solid mechanics, material science, and ultra-precision machining, can solve the problems that limit the rapid development of micro-nano torsion mechanics testing technology, and achieve the effect of compact structure, exquisite structure, and small error of rotation angle measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

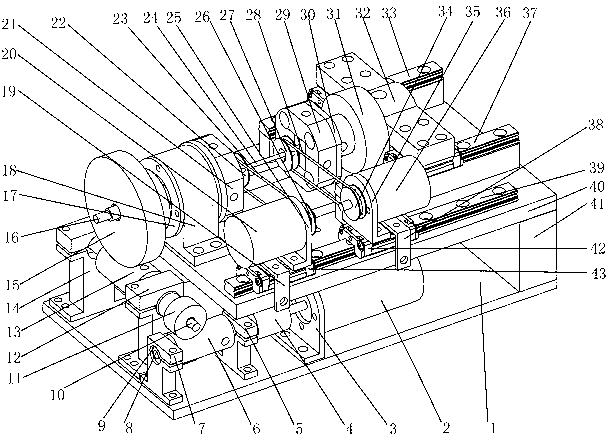

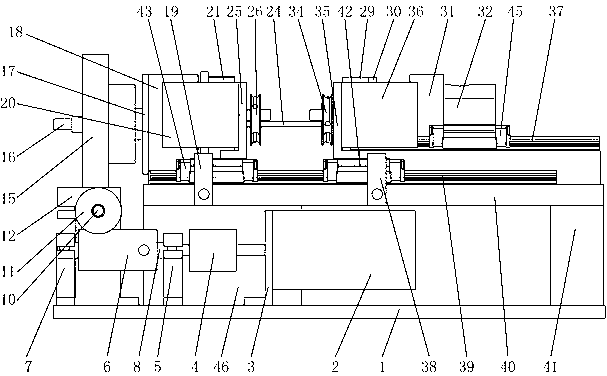

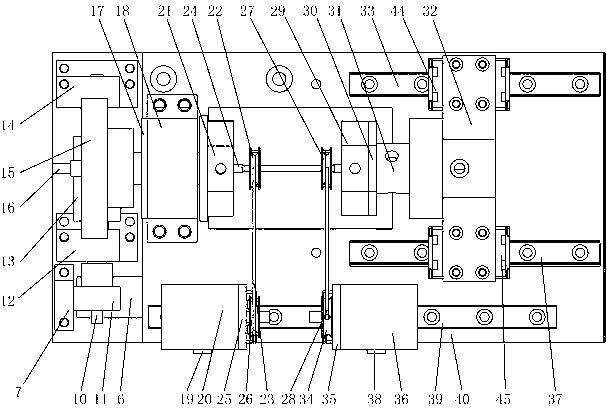

[0019] see Figure 1 to Figure 4 As shown, the in-situ torsion test platform for micromechanical properties of precision materials of the present invention is mainly composed of a torque loading mechanism, a specimen clamping mechanism, a precise torque measurement mechanism, and a precise rotation angle measurement mechanism.

[0020] The loading of torque is realized by the precision driving motor 2 and the worm gear transmission chain. The specific implementation method is that the precision driving motor 2 installed on the base I1 connects the worm shaft I8 through the elastic coupling 4, and drives the worm I6 and the worm gear. I11, through the worm gear shaft II10 installed on the bearing support III12 and bearing support IV14, as well as the worm II13 and the worm gear II15, through the reversing of the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com