Torsional testing machine for cable

A torsion testing machine and cable technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as difficulty in meeting cable testing requirements, and achieve the effects of reliable use, convenient operation, and continuous and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

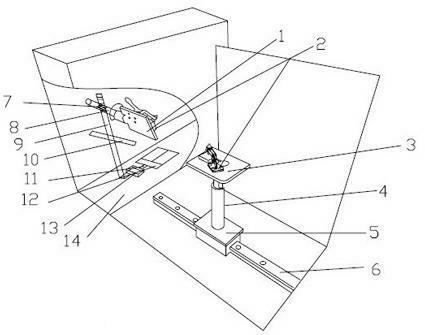

[0013] Such as figure 1 As shown, the cable torsion testing machine includes a driving motor 12, a bracket 10 and a base plate 14, the bracket 10 is fixedly connected to the base plate 14, the driving motor 12 is mounted on the base plate 14, and the motor output shaft 11 of the driving motor 12 is connected to the transmission through a converter 13. The arm 9 is connected, and the motor output shaft 11 rotates so that the transmission arm 9 reciprocates up and down; the transmission arm 9 meshes with the gear 7 fixed on the rotation shaft 8 to drive the rotation shaft 8 to rotate; the two ends of the rotation shaft 8 each Bearing is housed, and bearing is installed in the bearing seat, and rotating shaft 8 is fixedly installed on the frame by bearing seat, and rotating disc 1 is also housed on one end of rotating shaft 8, and rotating disc 1 is fixedly connected fixture 2 by screw.

[0014] A guide rail 6 is fixedly installed on the base plate 14, and a sliding seat 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com