Steel-concrete composite column anti-seismic anti-torsion test loading device and manufacturing method thereof

A technology of torsion test and loading device, which is applied in the direction of measuring device, using stable bending force to test the strength of materials, instruments, etc., can solve the problems of small stable loading stroke, single loading mode, lack of test data, etc., and achieve universality Strong, guaranteed free torsion, broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The structure, processing and use of the present invention will be further described below in conjunction with the accompanying drawings.

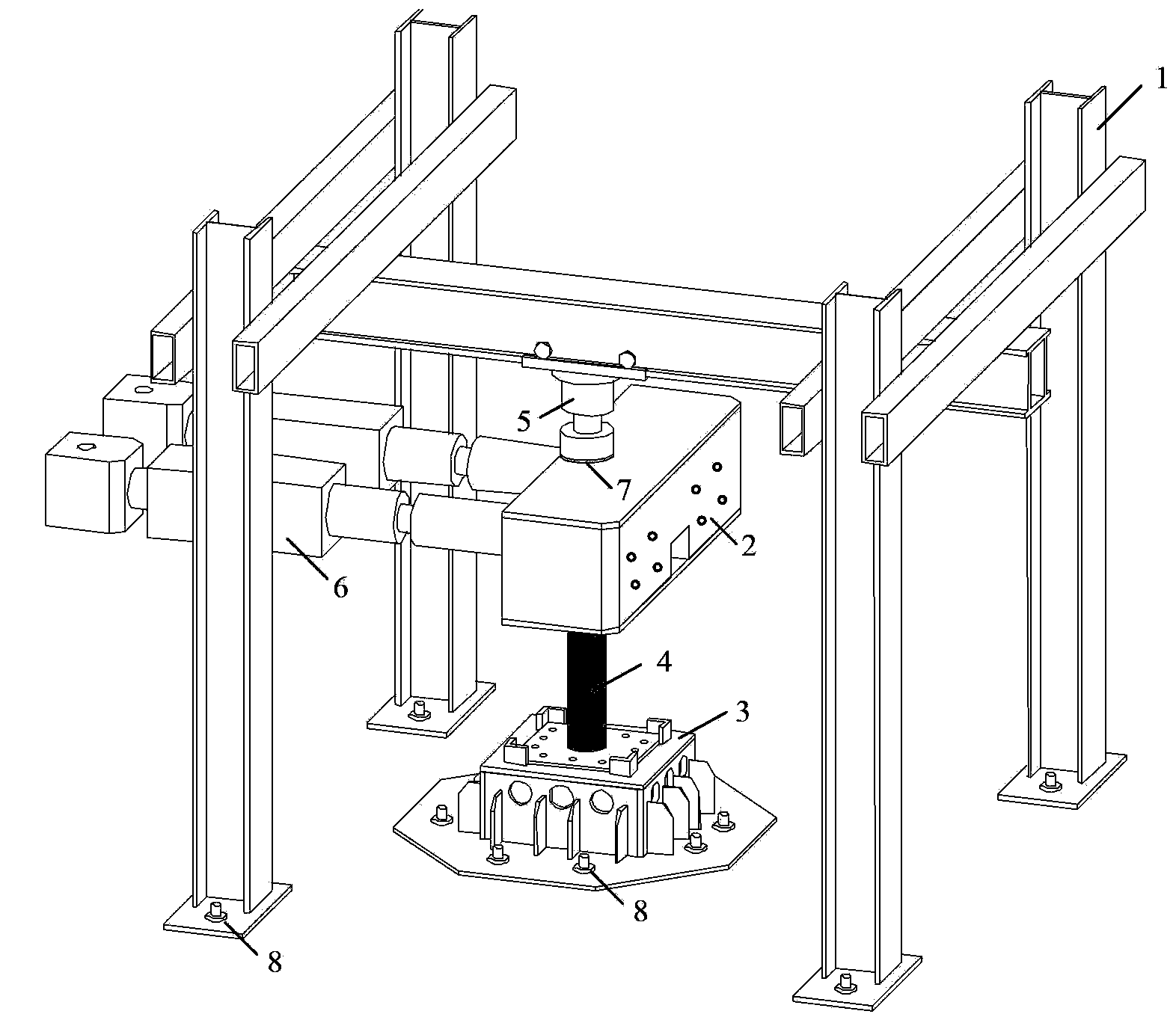

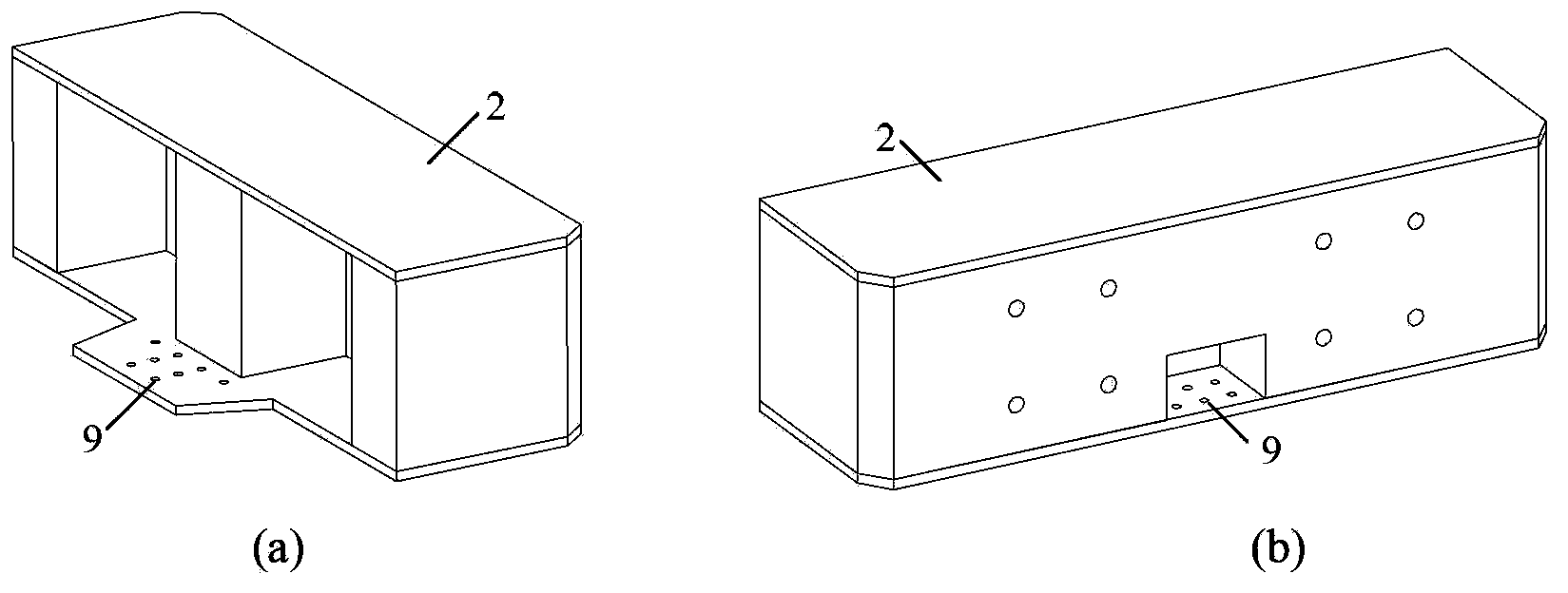

[0027] like figure 2 As shown, the device of the present invention includes a loading frame 1 , a top beam 2 , a base 3 , a test piece 4 , a thrust jack 5 , an electro-hydraulic servo actuator 6 , a friction-reducing plate 7 , and ground anchor bolts 8 . The structure of the top beam is as follows image 3 As shown, the base is constructed as Figure 4 As shown, the structure of the test piece is as follows Figure 5 shown.

[0028] The loading frame 1 is welded by steel plates, and each column foot of the loading frame is provided with a bolt hole 9, which is fixed to the ground through ground anchor bolts.

[0029] The top beam 2 is welded by steel plates, and the bottom of the top beam is provided with bolt holes 9, which are fixed to the top plate 11 of the test piece 4 through the bolts, so as to ensure the close connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com