Device for testing micro-torsion mechanical property of low-dimension material

A low-dimensional material and testing device technology, applied in the direction of using stable torsion to test the strength of materials, can solve problems such as low efficiency in reading angle data, inconvenient clamping and centering, and difficult calibration of driving force. The effect of stable results, reliable measurement results and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

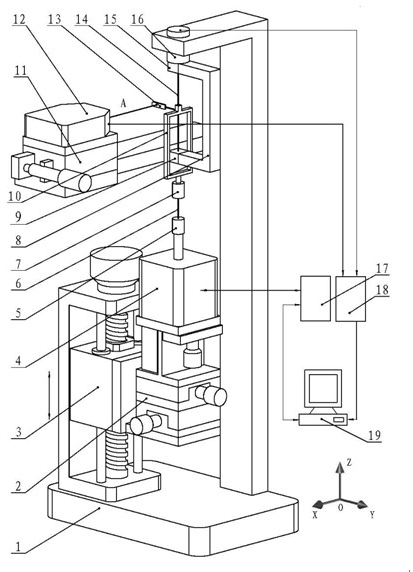

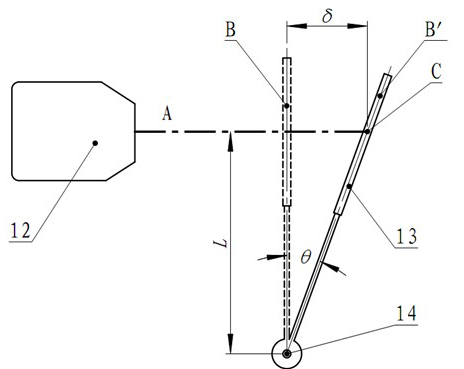

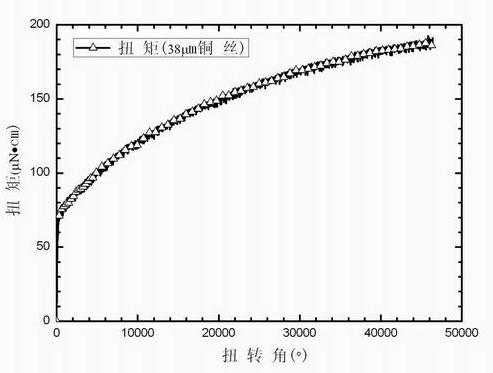

[0037] The twisted wire of the micro torque sensor in the device is pure tungsten wire with a diameter of 80 μm, the length of the upper and lower twisted wires is 20 cm, the resolution is 0.5 μN·cm, and the measuring range is ±6000 μN·cm. The force sensor has a resolution of 0.1mN and a measuring range of ±5N. The selected photoelectric displacement sensor has a resolution of 1 μm and a measuring range of ±15 mm, and uses triangulation to measure the rotational distance of the target surface. The selected stepper motor has a minimum step angle of 0.0072°. The stroke of the screw nut assembly is 200mm, the stroke of the one-dimensional translation stage is 20mm, and the strokes of the three-dimensional translation stage X, Y, and Z are all 10mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com