Patents

Literature

103 results about "Digital collections" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

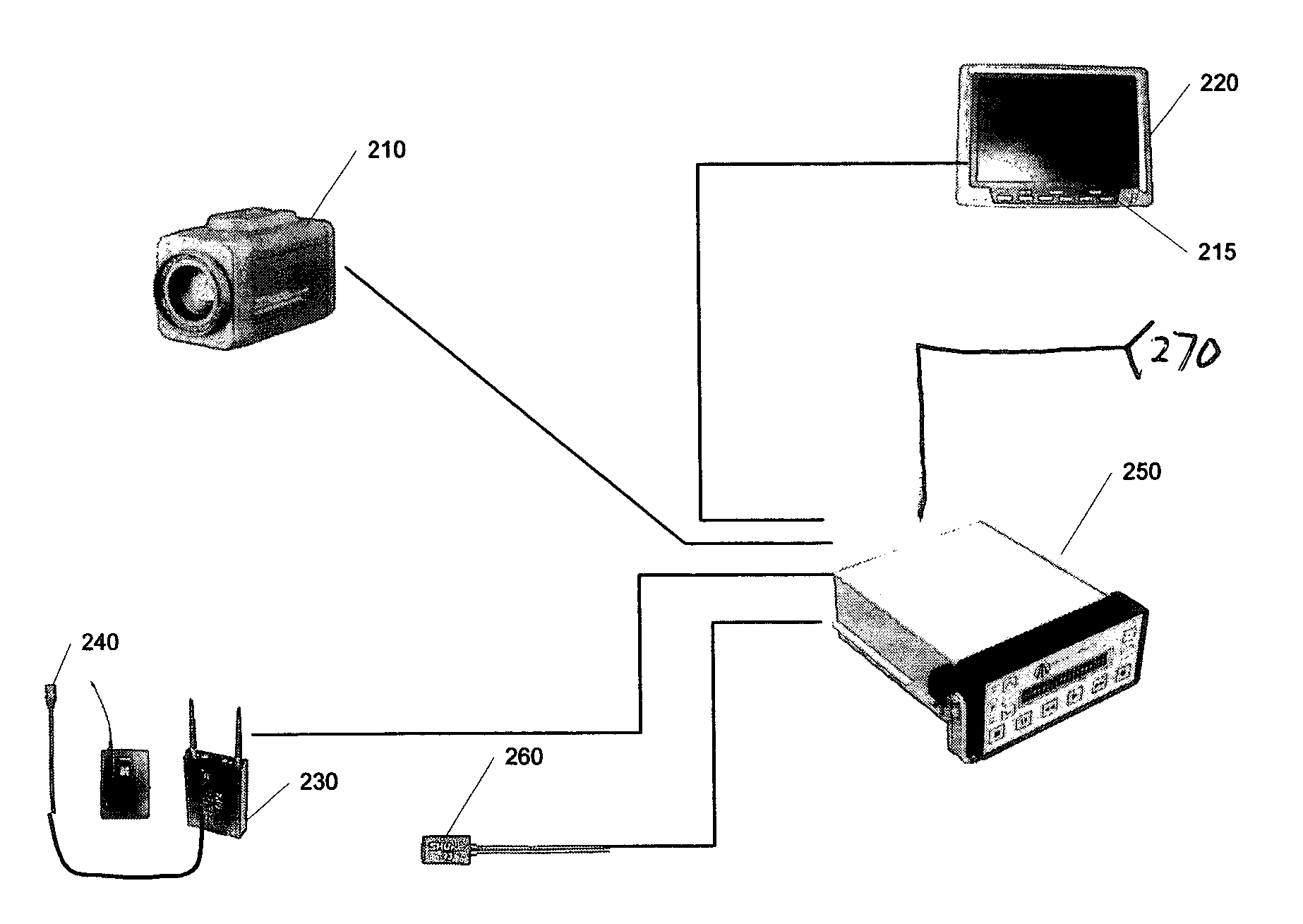

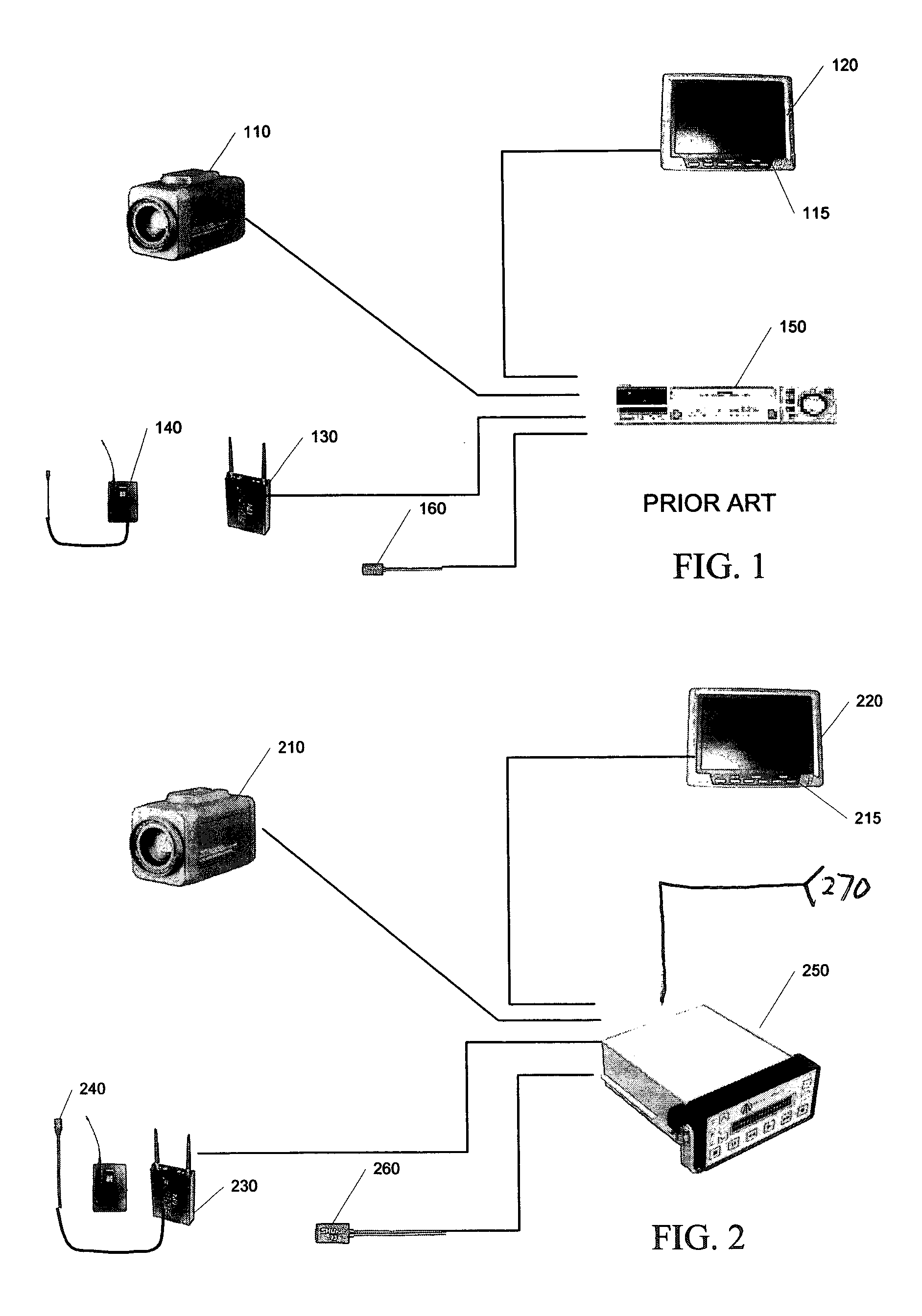

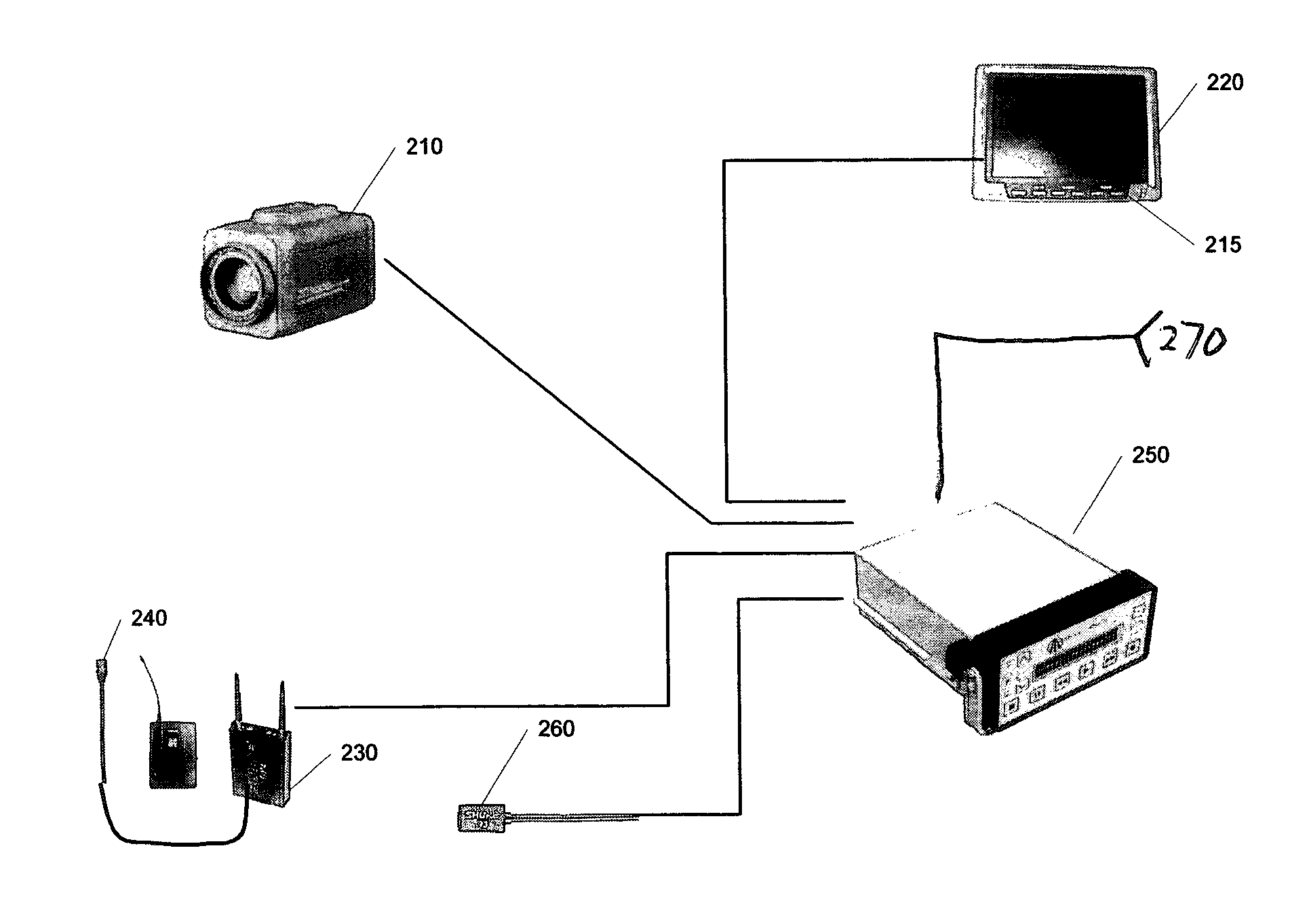

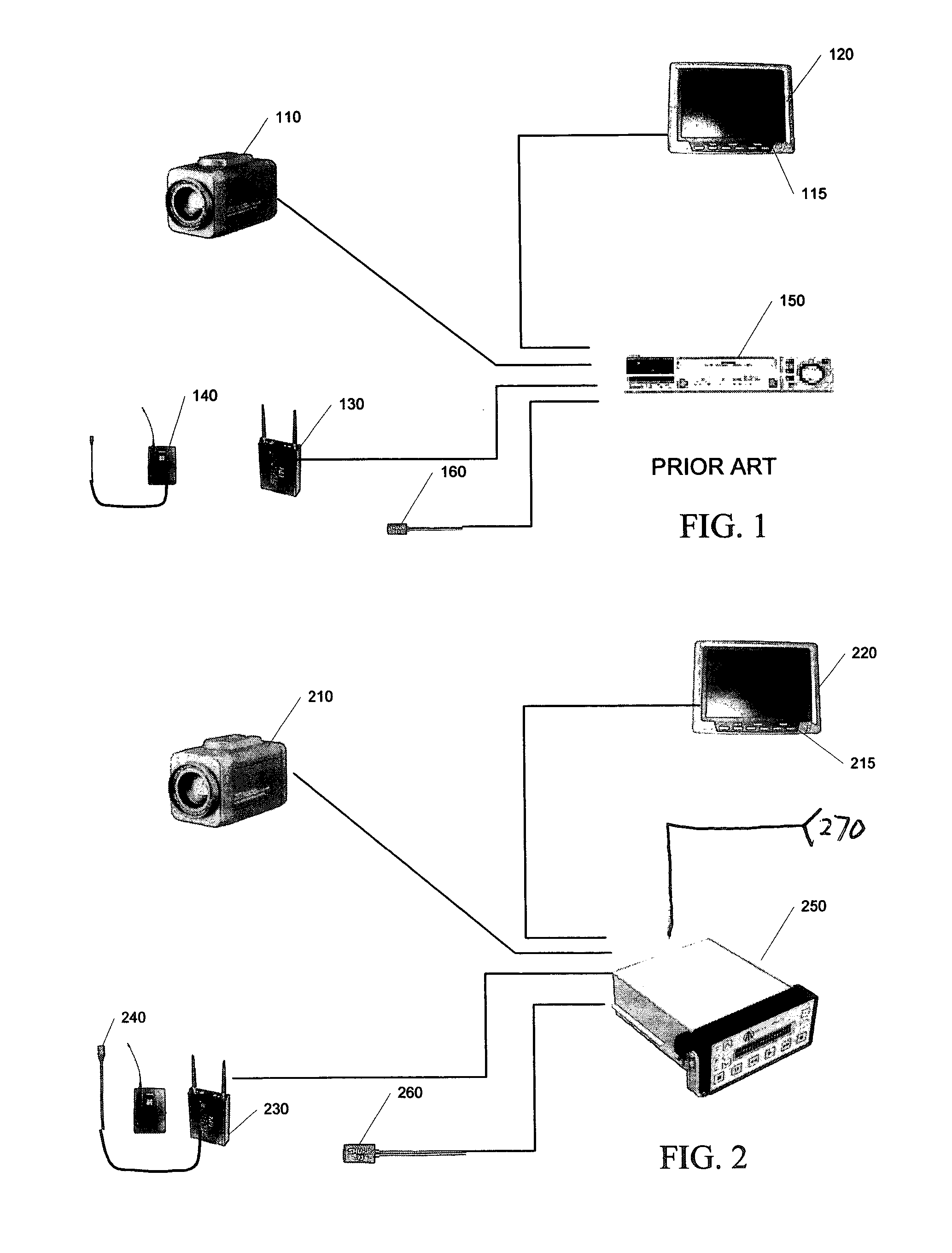

Digital video system-intelligent information management system

InactiveUS20050099498A1Efficient managementAutomate managementTelevision system detailsColor television signals processingDigital videoDigital collections

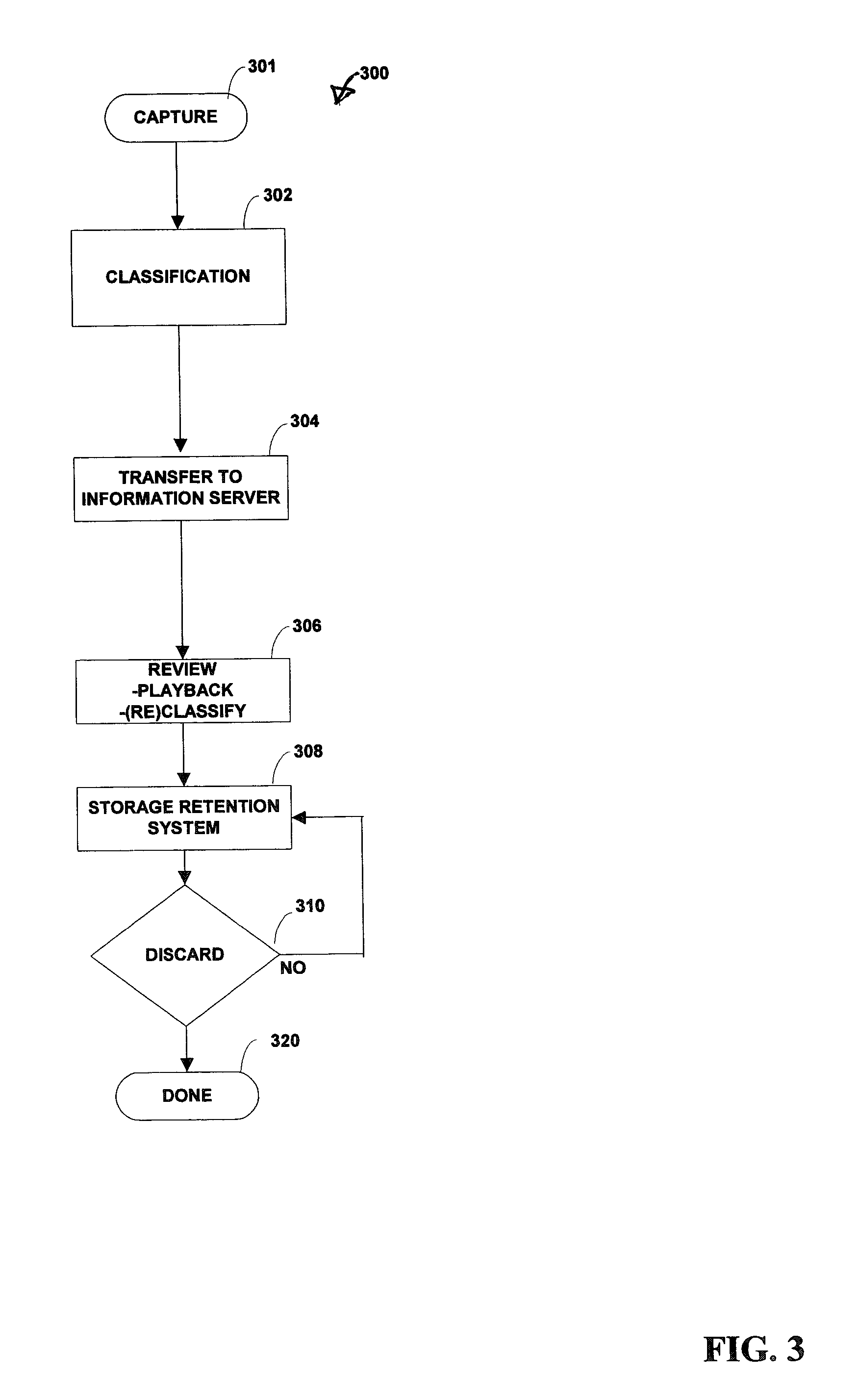

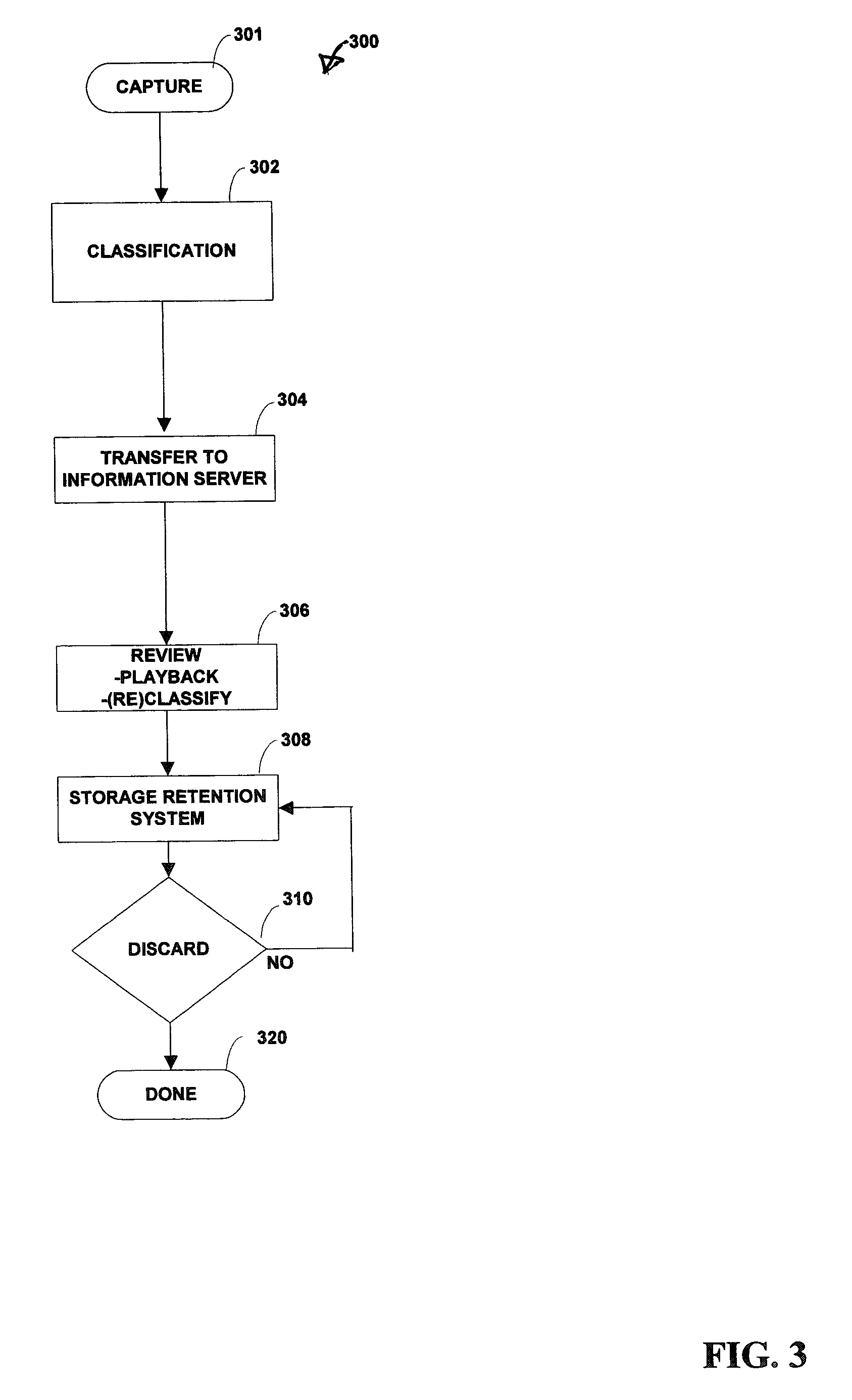

A digital video information management system for monitoring and managing a system of digital collection devices is disclosed. Information files are automatically transferred from such collection devices to the information management system. Digitally captured information is classified to assign information attributes which are used to categorize and establish management, storage, and retention characteristics. A unique file, filename, and attributes are created for each recorded event, allowing the information management system to manage each event efficiently. The information management system automates a process to transfer digital information to other users or network-connected devices. Transfer of digital information can be done on a scheduled basis, or in response to an information request, or upon instruction by an end user. Information transferred from digital collection devices at geographically dispersed sites to the information management system are synchronized or “rolled-forward” to a master or mirrored database. Information is erased or deleted from a digital collection device once the information has been transferred to the storage and retention system of the information management system. The status of any given digital collection device is automatically determined and configuration and software updates are downloaded to the device as required. A centralized time reference may be used to synchronize such digital recording devices.

Owner:INTEGRIAN

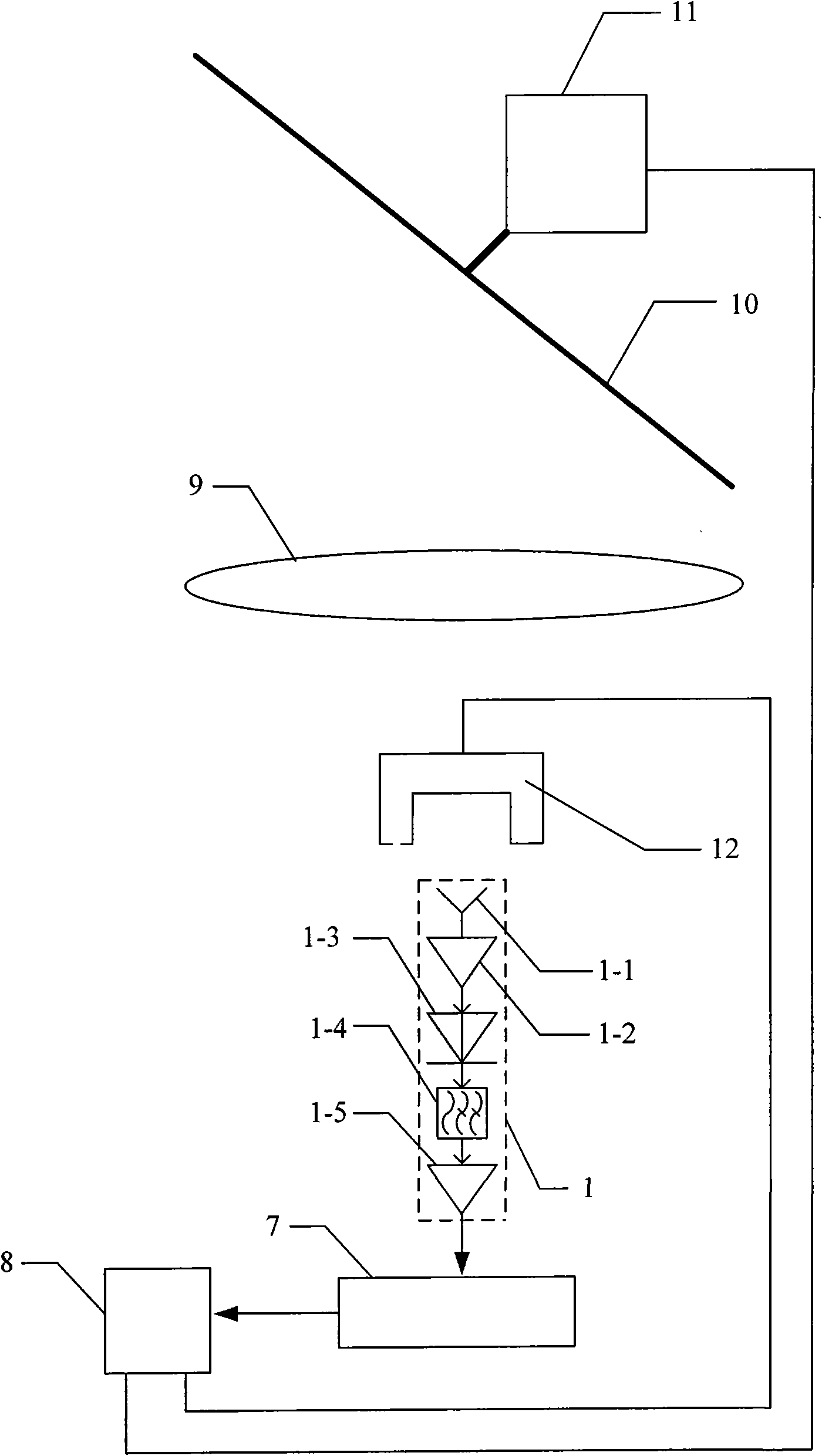

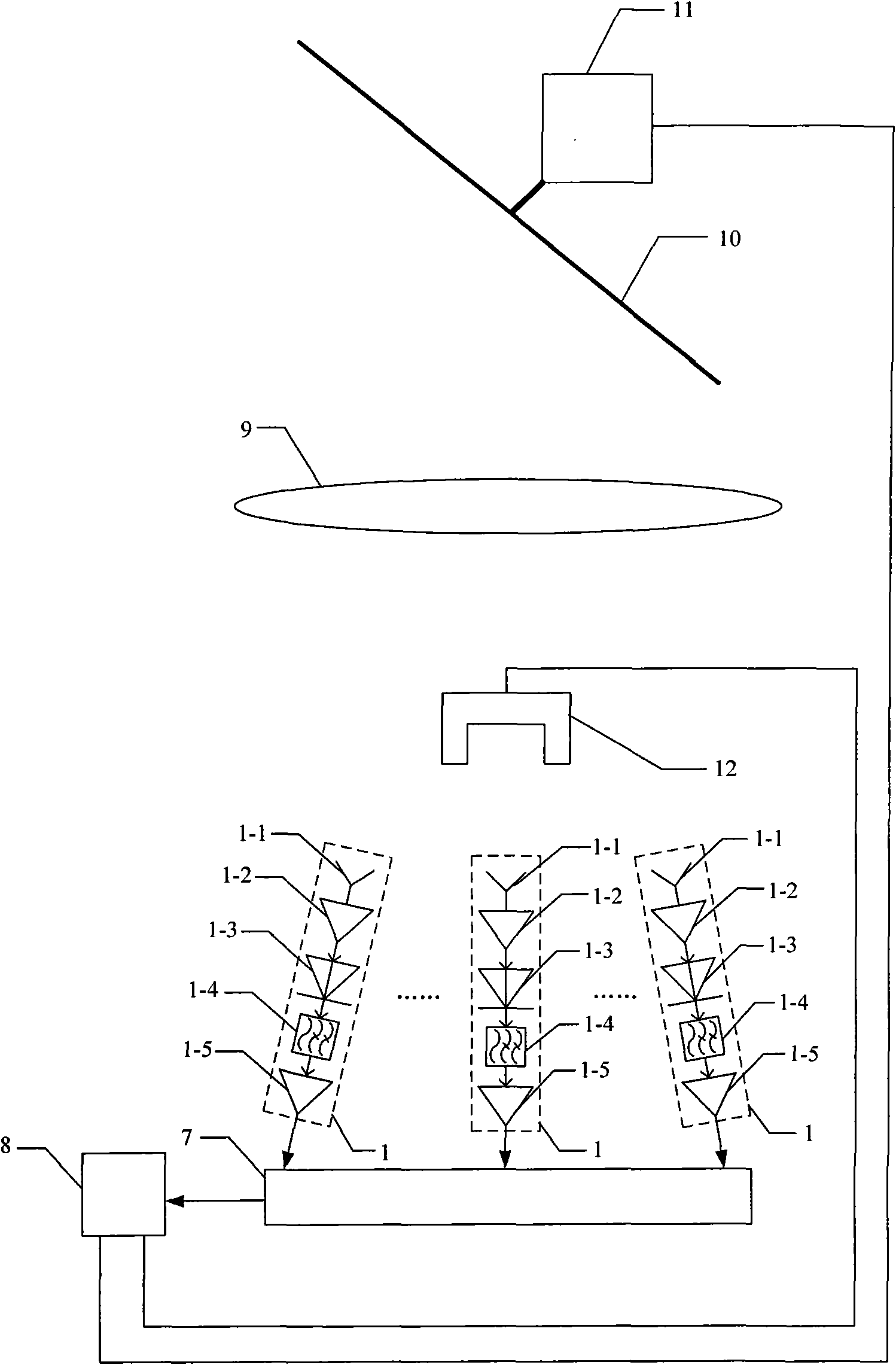

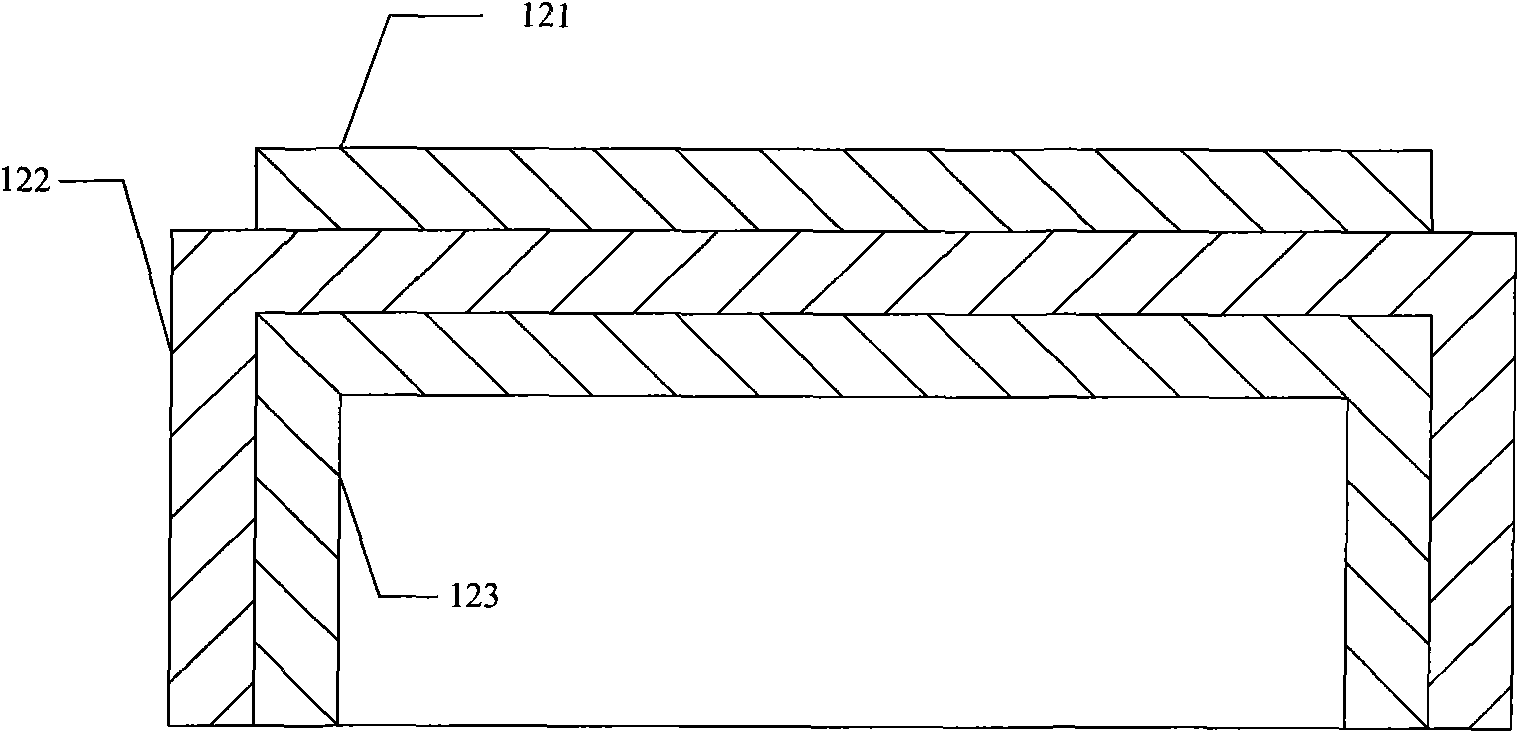

Passive millimeter wave imaging system

ActiveCN101644770AHigh resolutionImaging time is shortRadio wave reradiation/reflectionLow-pass filterMillimeter

The invention discloses a passive millimeter wave imaging system and relates to a millimeter wave imaging system. The passive millimeter wave imaging system solves the problems of long imaging time ofthe system, poor real-time property and low resolution of an obtained image caused by the way of focal plane array imaging of the existing millimeter wave imaging system. A metal reflection plate ofthe passive millimeter wave imaging system reflects electromagnetic waves radiated by a target to be tested onto a receiving antenna by aggregation via a medium lens, the received signals are processed by a millimeter wave band high-gain low-noise amplifier, a high-sensitivity square law detector, a low-pass filter and a low-frequency amplifier in sequence and then collected by a digital collection circuit, and the collected signals are transmitted into a computer for carrying out imaging processing. The passive millimeter wave imaging system is applicable to the field of security.

Owner:HARBIN INST OF TECH

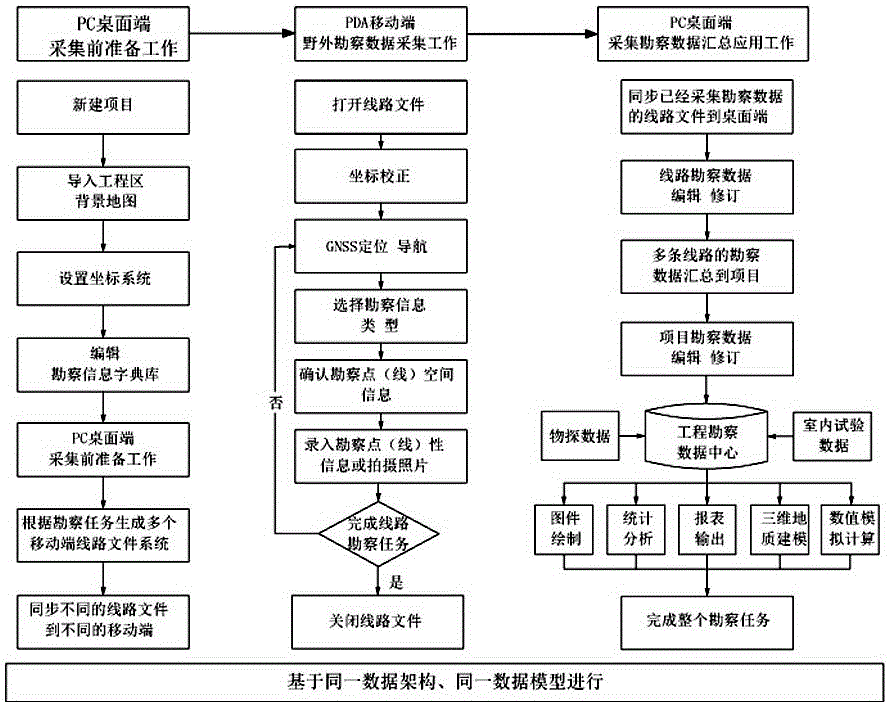

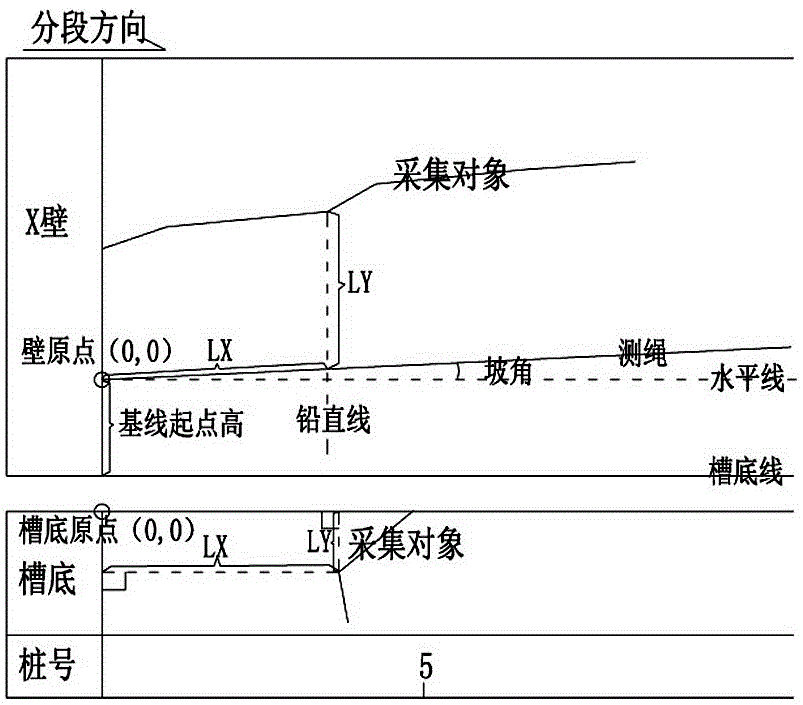

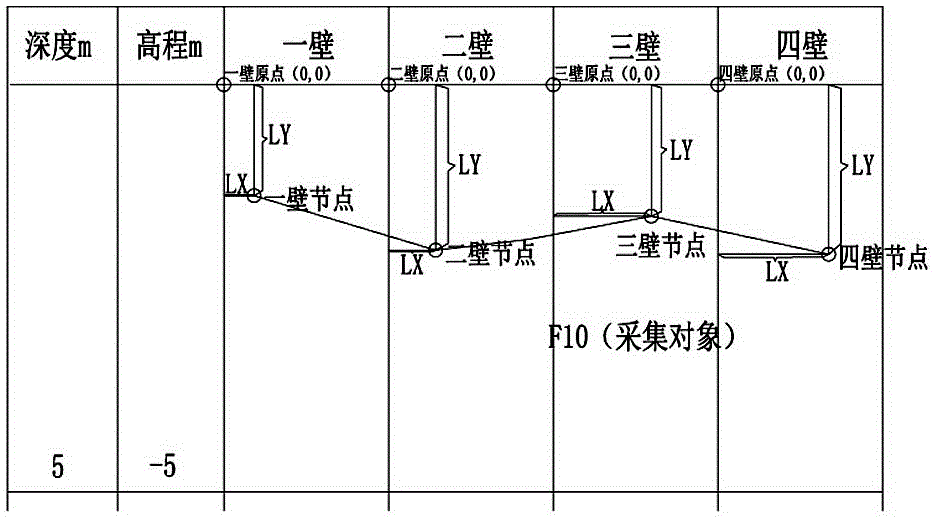

Engineering investigation information digital collection, management and integrated application method

InactiveCN106779417AConvenient post-management applicationReal-time query of geological attributesDatabase distribution/replicationResourcesDigital collectionsInformation resource

The invention discloses an engineering investigation information digital collection, management and integrated application method. The method is realized jointly through a desktop management subsystem and a mobile device collection subsystem and completed at a PC desktop terminal and a PDA mobile terminal, and the whole process is carried out based on the same data architecture and the same data model. The method and technology for engineering investigation information resource collection and production, organization and management to diversified utilization are suitable for collection, management and utilization of investigation information resources in all industries and can be directly applied and popularized in engineering investigation of all industries.

Owner:YELLOW RIVER ENG CONSULTING

Digital video system-intelligent information management system

InactiveUS20060012683A9Efficient managementAutomate managementTelevision system detailsColor television signals processingDigital videoDigital collections

A digital video information management system for monitoring and managing a system of digital collection devices is disclosed. Information files are automatically transferred from such collection devices to the information management system. Digitally captured information is classified to assign information attributes which are used to categorize and establish management, storage, and retention characteristics. A unique file, filename, and attributes are created for each recorded event, allowing the information management system to manage each event efficiently. The information management system automates a process to transfer digital information to other users or network-connected devices. Transfer of digital information can be done on a scheduled basis, or in response to an information request, or upon instruction by an end user. Information transferred from digital collection devices at geographically dispersed sites to the information management system are synchronized or “rolled-forward” to a master or mirrored database. Information is erased or deleted from a digital collection device once the information has been transferred to the storage and retention system of the information management system. The status of any given digital collection device is automatically determined and configuration and software updates are downloaded to the device as required. A centralized time reference may be used to synchronize such digital recording devices.

Owner:INTEGRIAN

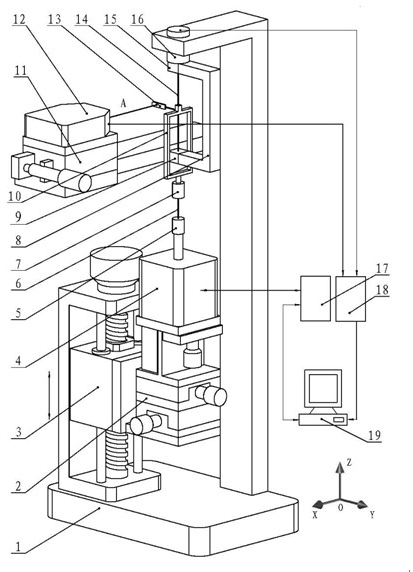

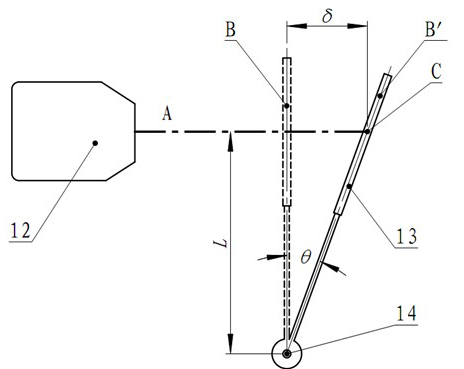

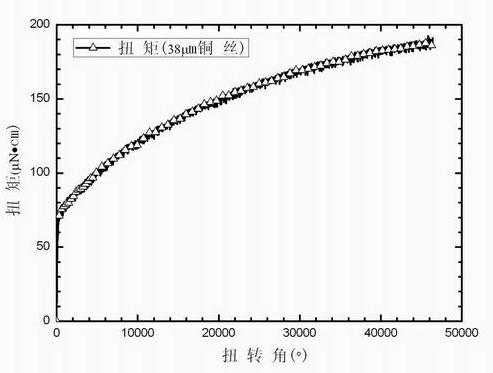

Device for testing micro-torsion mechanical property of low-dimension material

InactiveCN102183418AEasy clampingClamping real-time detectionMaterial strength using steady torsional forcesTorsion testEngineering

The invention provides a device for testing the micro-torsion mechanical property of a low-dimension material. The device comprises a stander, a force sensor, a micro-torsion sensor, a torsion wire rotation angle measurement component, an upper chuck, a lower chuck, a stepping motor, a three-dimensional translation table, a screw and nut component, a servo controller, an analog-to-digital collection card and a computer system, wherein both ends of a tension wire of the micro-torsion sensor are tensioned and fixed on a bracket and have high rigidity and stability; by replacement of the torsion wire, a measurement range can be adjusted; moreover, the force sensor is arranged at the upper end of the micro-torsion sensor, so that an axial force during torsion test can be detected in real time. In the device, a rotation angle of the torsion wire is measured in a manner of combining a light target and a photoelectric displacement sensor; and compared with a conventional light lever method, the device has a compact structure, high automation degree and high stability. By regulation of the three-dimensional translation table, an upper chucking point and a lower chucking point can be aligned. The computer system can obtain a torque-rotation-angle curve of a test sample in real time. The device is applicable to micro-torsion mechanical property of the low-dimension material.

Owner:HUAZHONG UNIV OF SCI & TECH

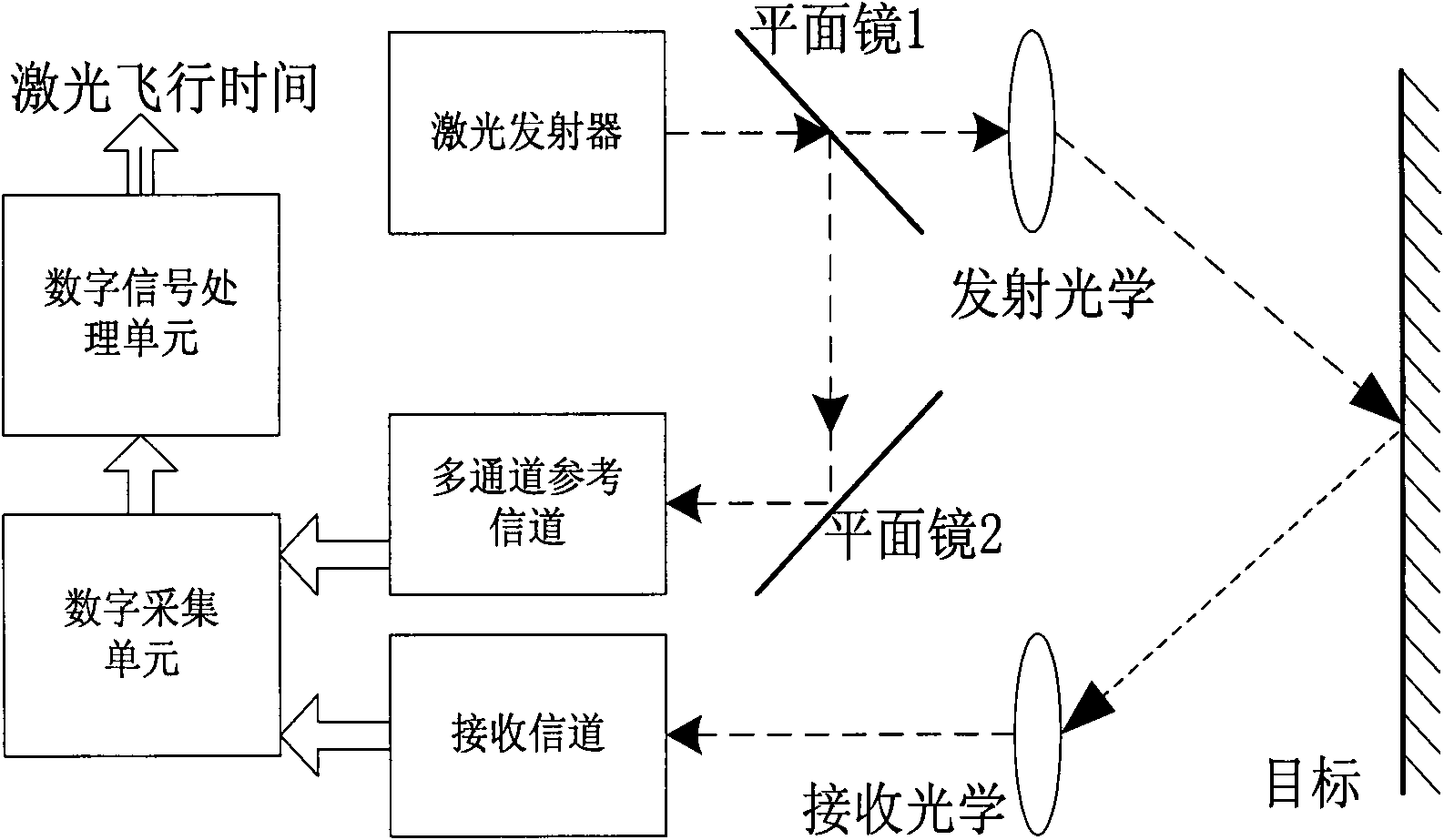

Laser time-of-flight measurement device based on multi-channel time delay estimation and method thereof

InactiveCN102176004AHigh measurement accuracyLarge timing errorWave based measurement systemsDigital signal processingLaser transmitter

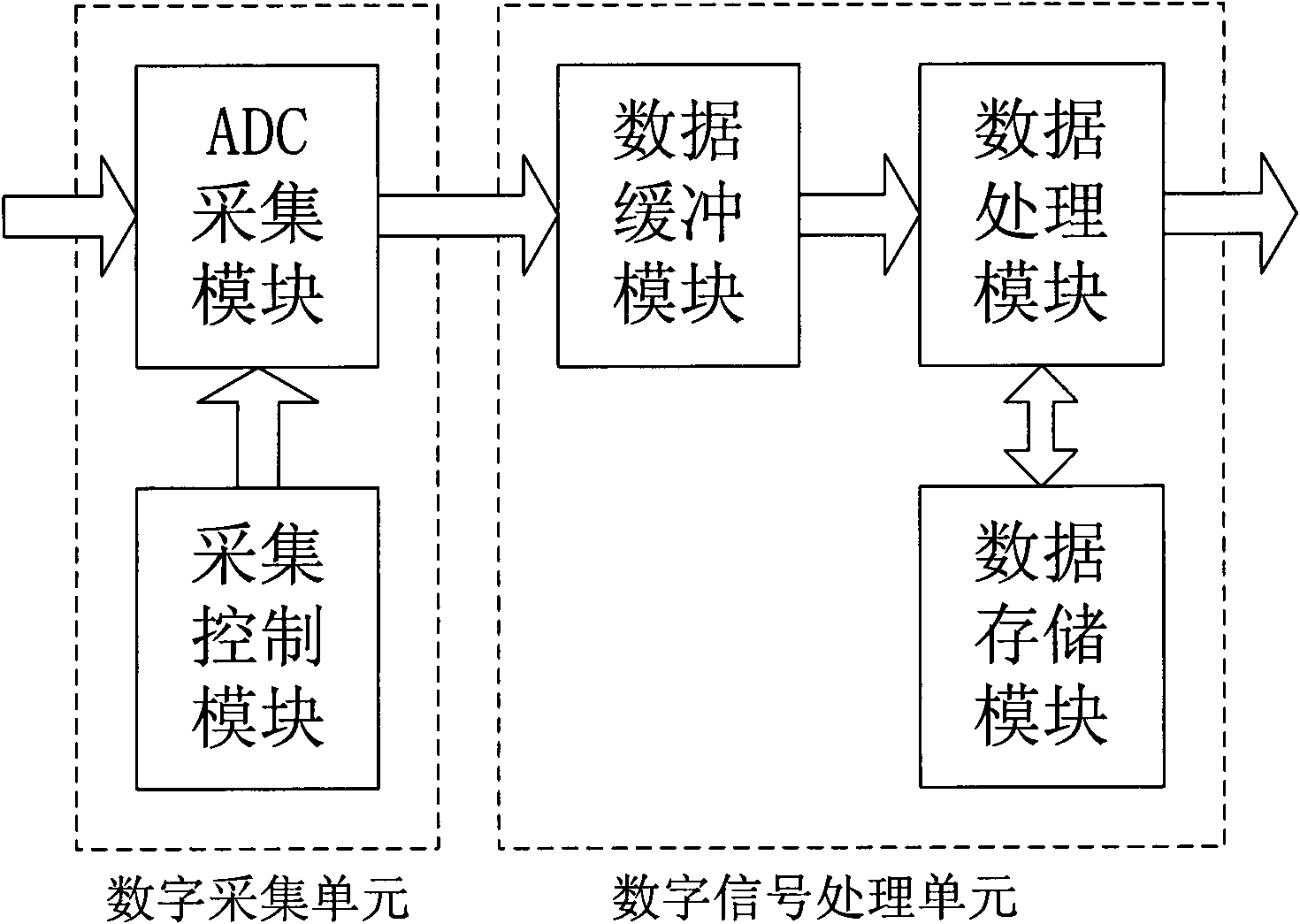

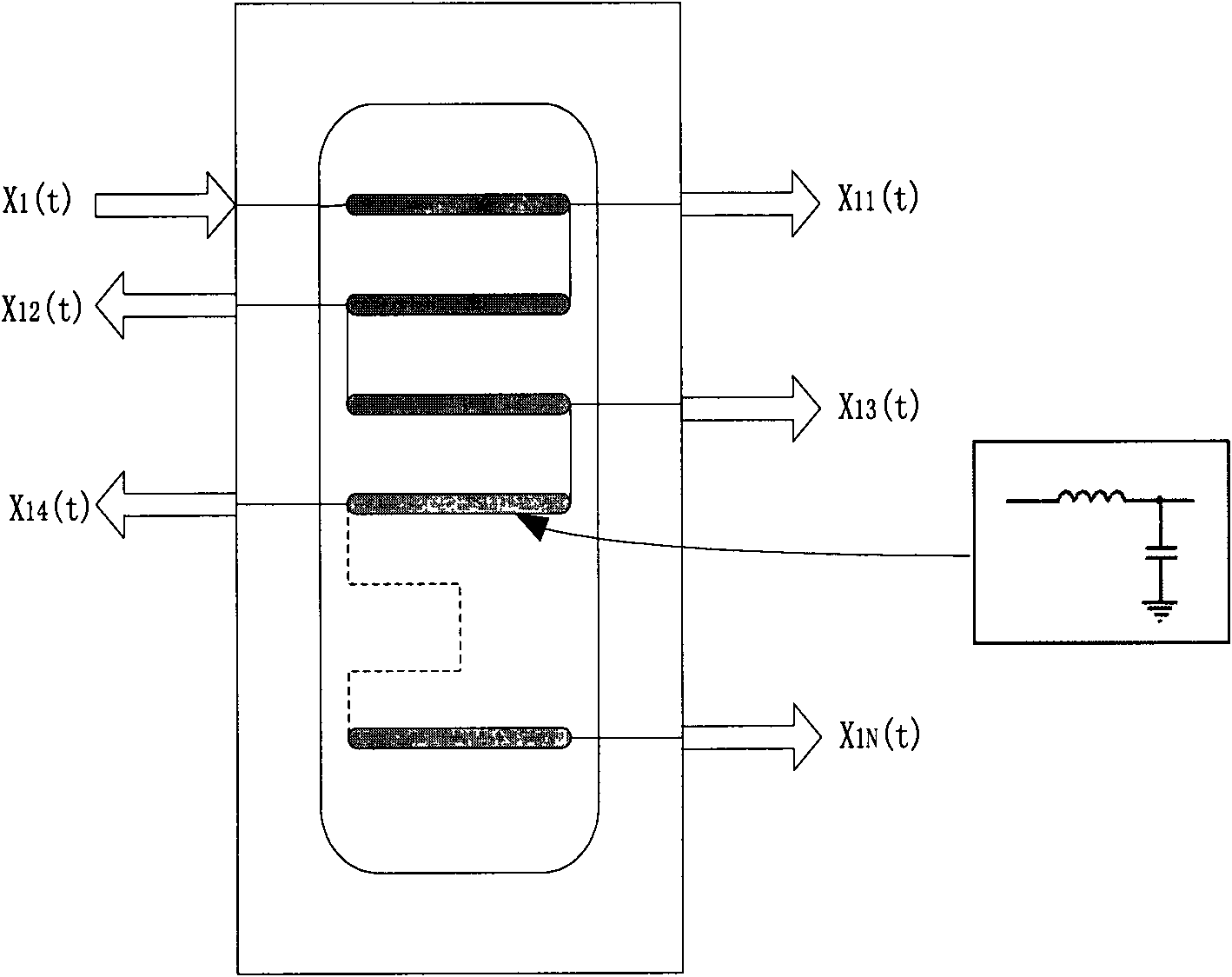

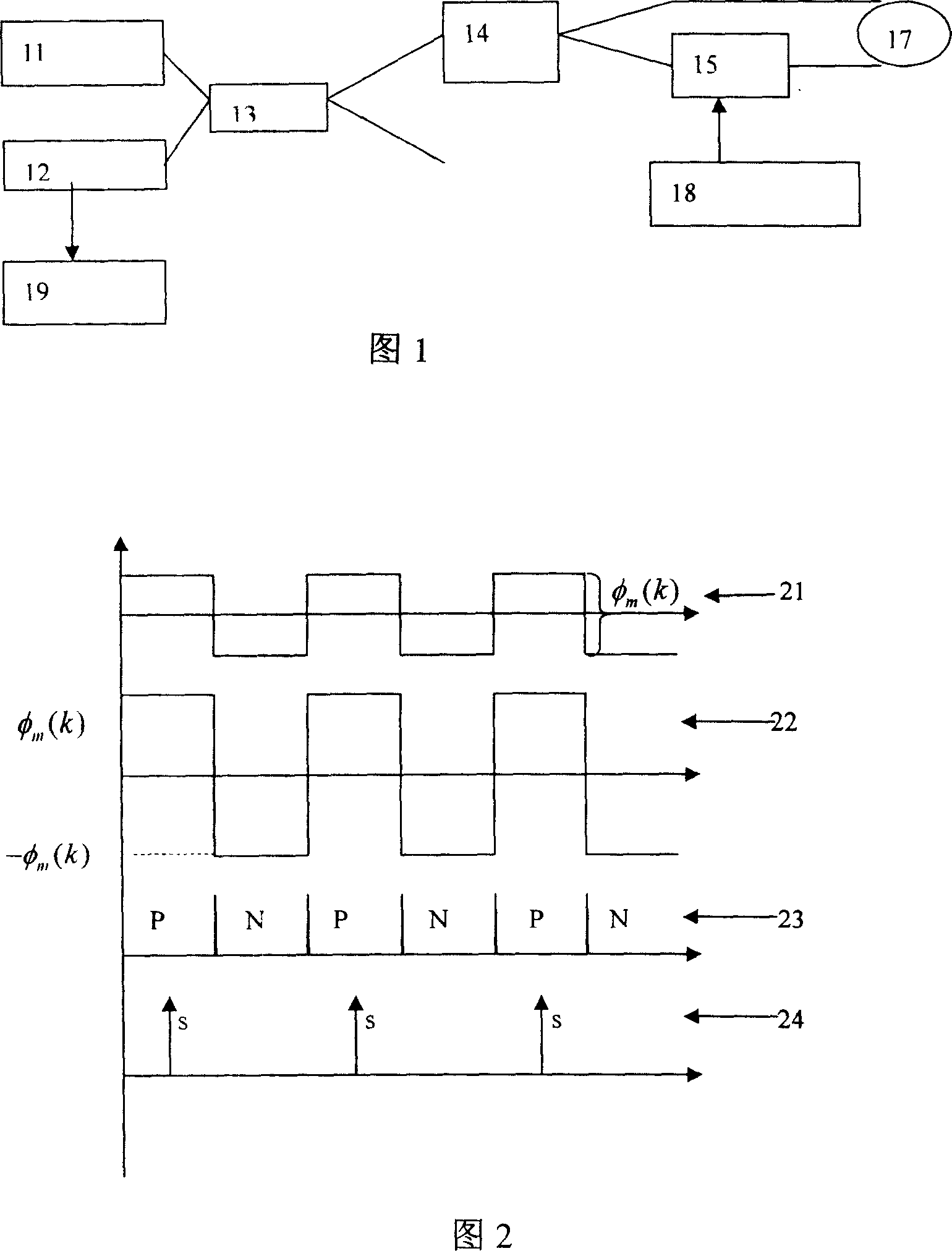

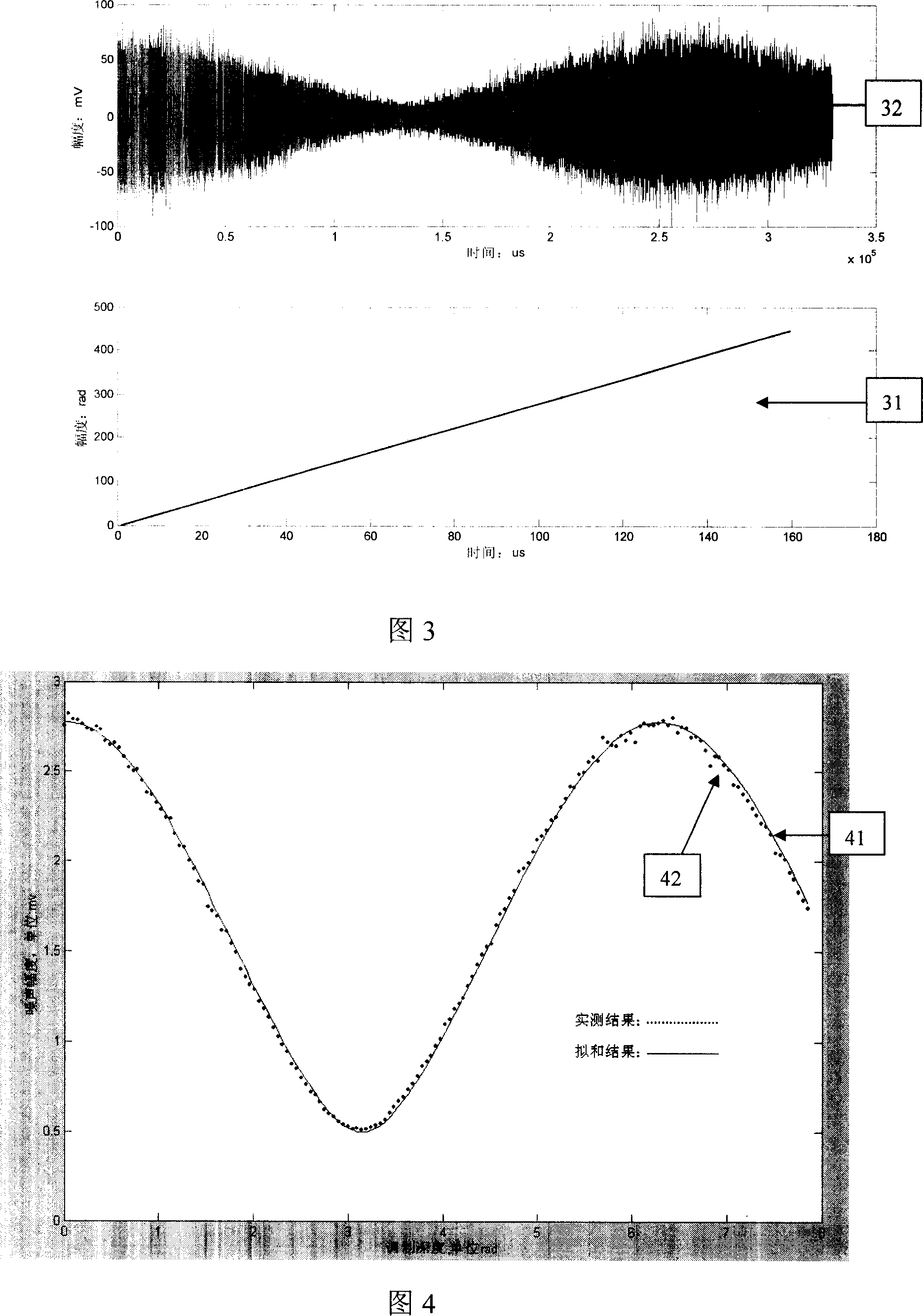

The invention discloses a laser time-of-flight measurement device based on multi-channel time delay estimation and a method thereof. The method comprises the following steps: firstly, opening a multi-channel reference channel and a receiving channel immediately when a laser emitter emits a laser beam; secondarily, performing delay-time processing on the signals by the multi-channel reference channel according to a fixed time interval to form multi-channel reference signals; and finally, transmitting the echo signals of the receiving channel and the multi-channel reference signals to a digitalsignal processing unit by a digital collection unit to carry out cross-correlation operation, and correcting the obtained different time delay estimation values by linear polynomial fitting to obtainthe optimal time delay estimation value. The method and the device are completely digitalized; the device is simple; and the method is effective, has small calculation amount and high stability and can effectively improve the measurement accuracy of the laser time-of-flight.

Owner:NANJING UNIV OF SCI & TECH

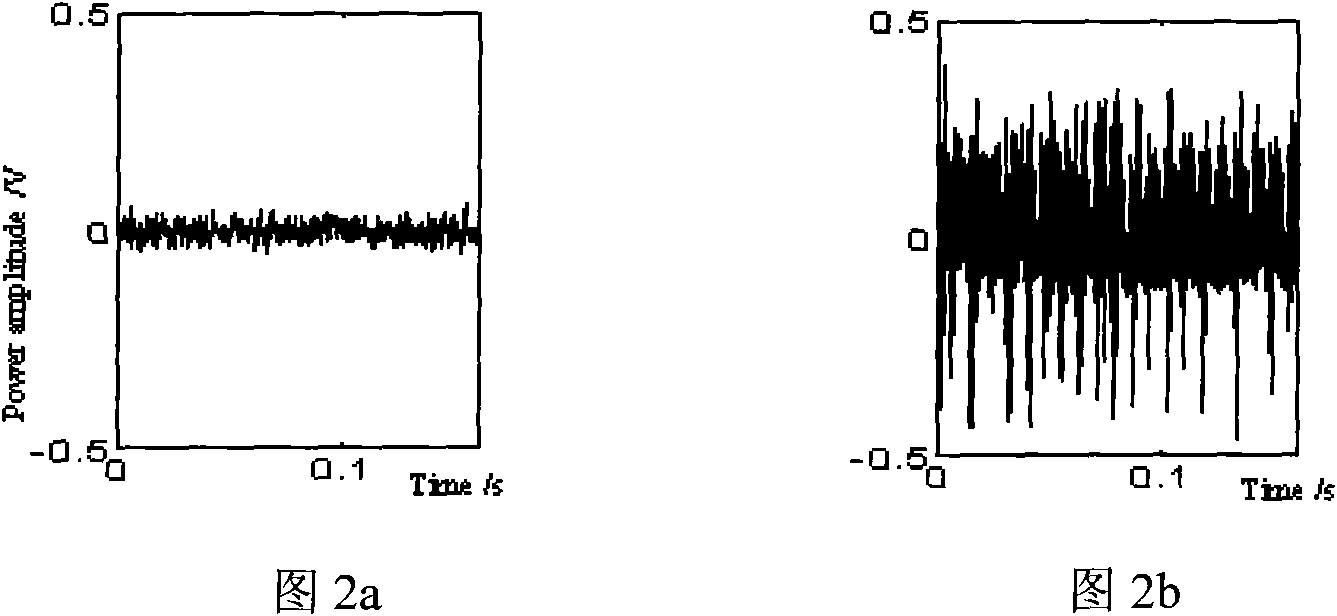

Method for separating thermal noise, shot noise and intensity noise of optical fiber gyroscope

InactiveCN101008570AImprove reliabilityHigh precisionSagnac effect gyrometersTransmission monitoring/testing/fault-measurement systemsFiberDigital collections

This invention discloses one light fiber top noise, discrete noise and intensity noise separation method, which comprises the following steps: processing phase modulation on system according to selection phase; high speed digital collection circuit processes sample of output signal in different modulation depth; through sample sequence analyzing getting relative noise even and variance; according to different function, computing three kinds of noise value.

Owner:ZHEJIANG UNIV

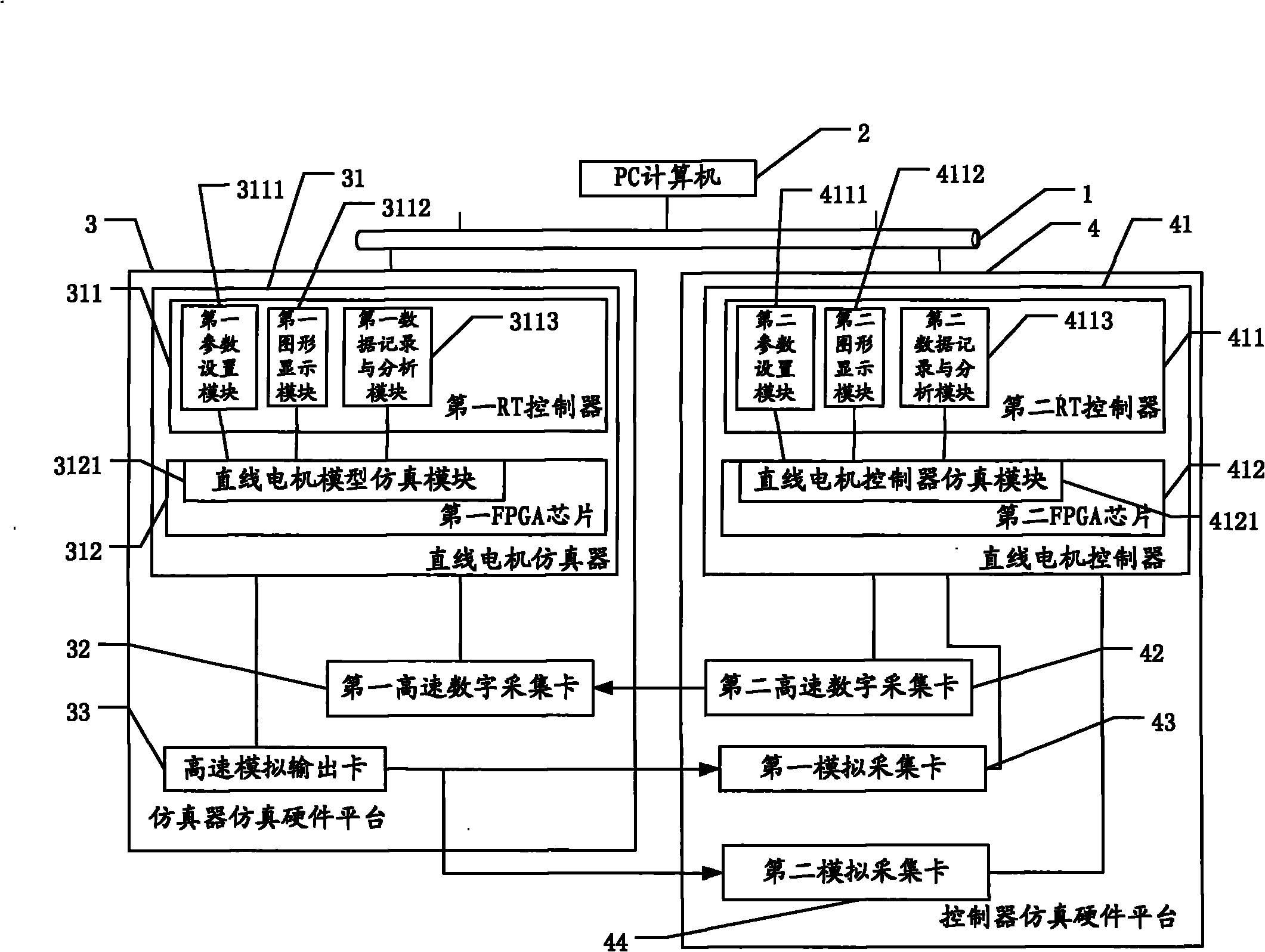

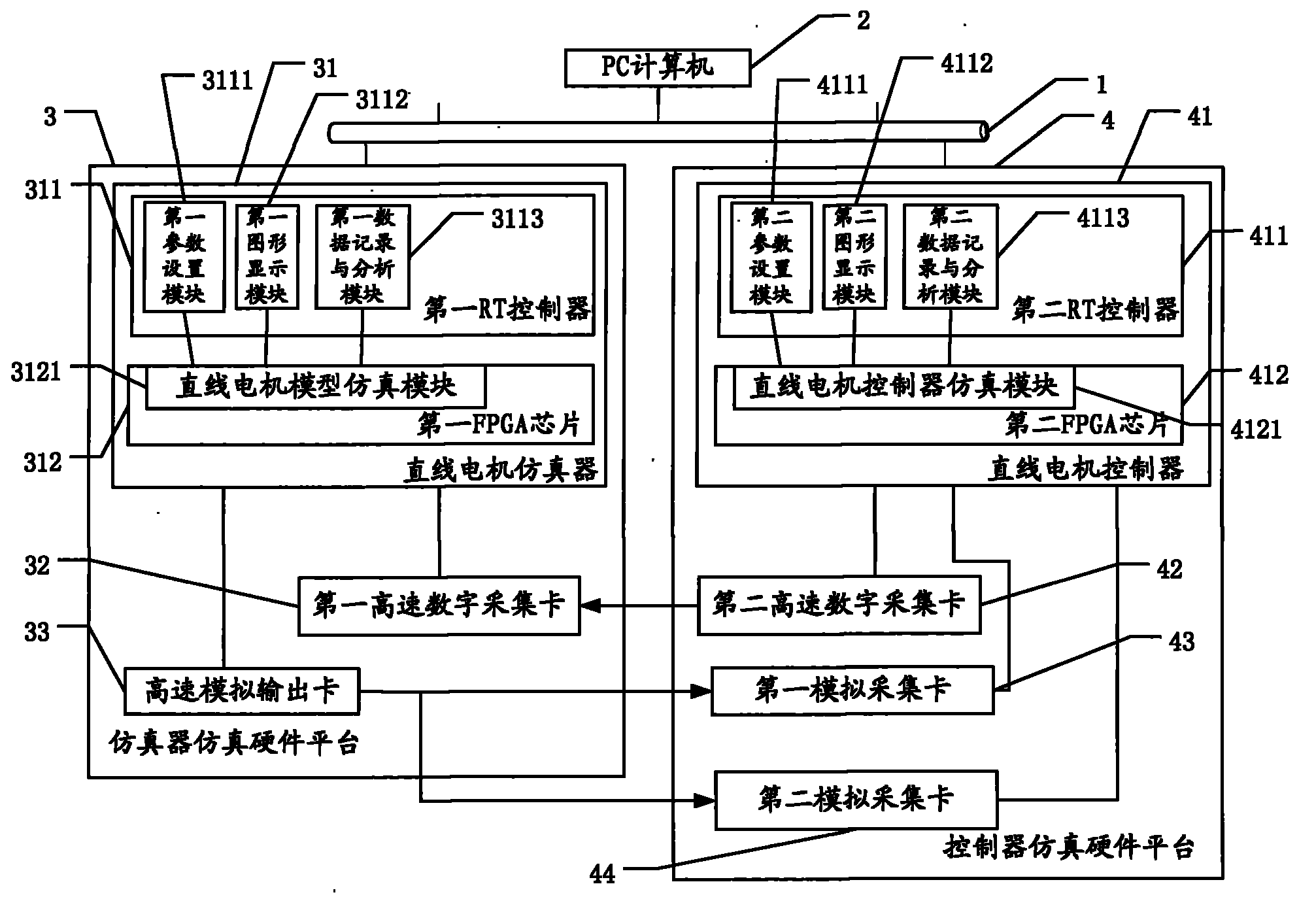

Hardware-in-the-loop (HIL) real-time simulation platform of permanent magnet linear synchronous motor

InactiveCN102110010ARealize closed-loop controlProof of correctnessSoftware simulation/interpretation/emulationReal-time simulationDigital collections

The invention discloses a hardware-in-the-loop (HIL) real-time simulation platform of a permanent magnet linear synchronous motor. The HIL real-time simulation platform comprises a personal computer (PC) connected with the Ethernet, a controller simulation hardware platform, and a simulator simulation hardware platform, wherein the simulator simulation hardware platform includes a linear motor simulator connected with the Ethernet, as well as a first high-speed digital collection card and a high-speed analog output card connected with the linear motor simulator; and the controller simulation hardware platform includes a linear motor controller connected with the Ethernet, as well as a second high-speed digital collection card, a first analog collection card and a second analog collection card connected with the linear motor controller. The HIL real-time simulation platform can rapidly and accurately track the given position and speed signals with the micrometer-level precision, and can on-line regulate the controller parameter and the linear motor loads.

Owner:SHANGHAI ELECTRICGROUP CORP

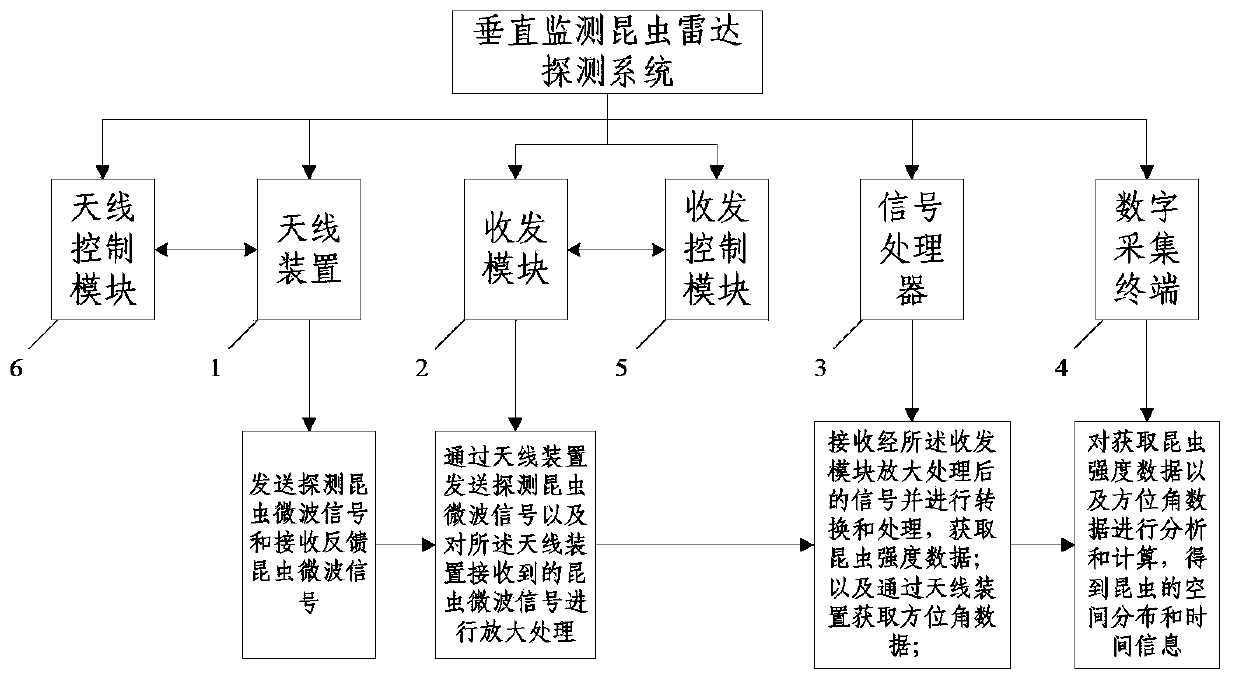

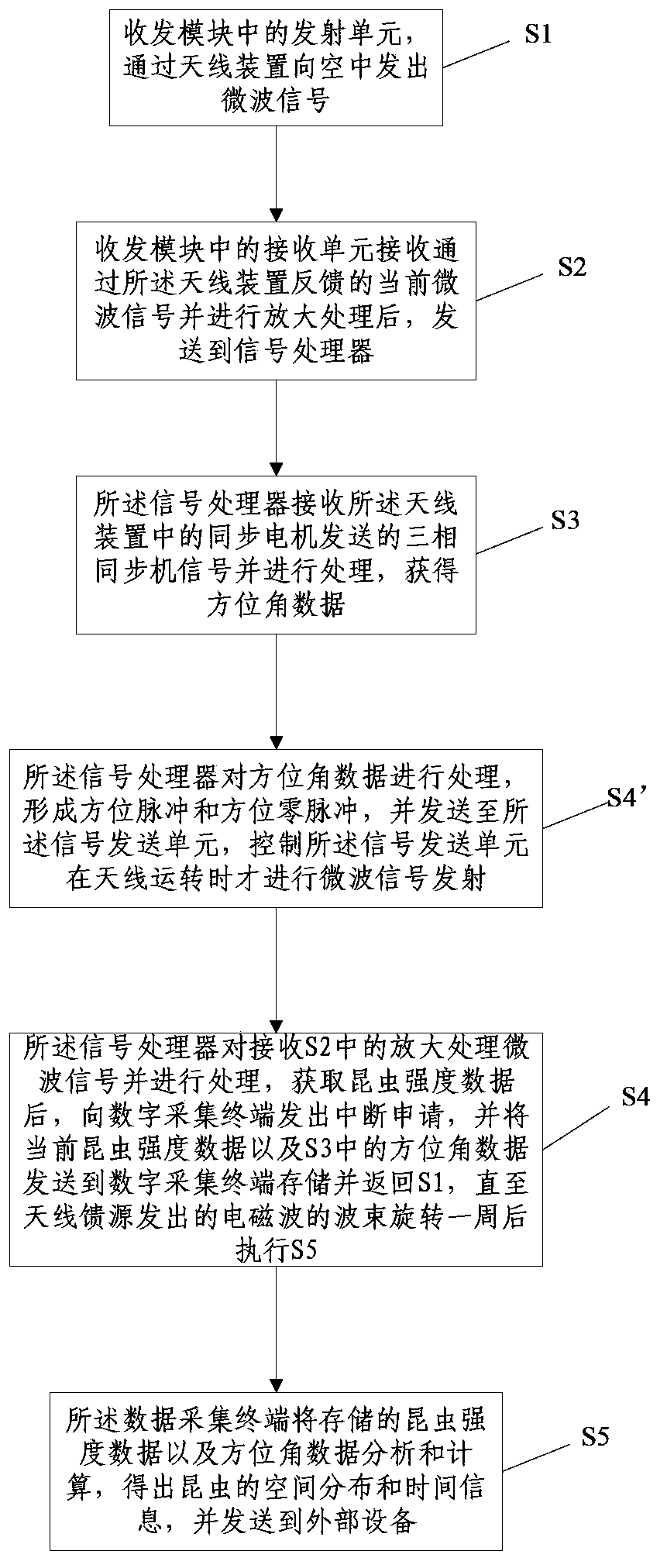

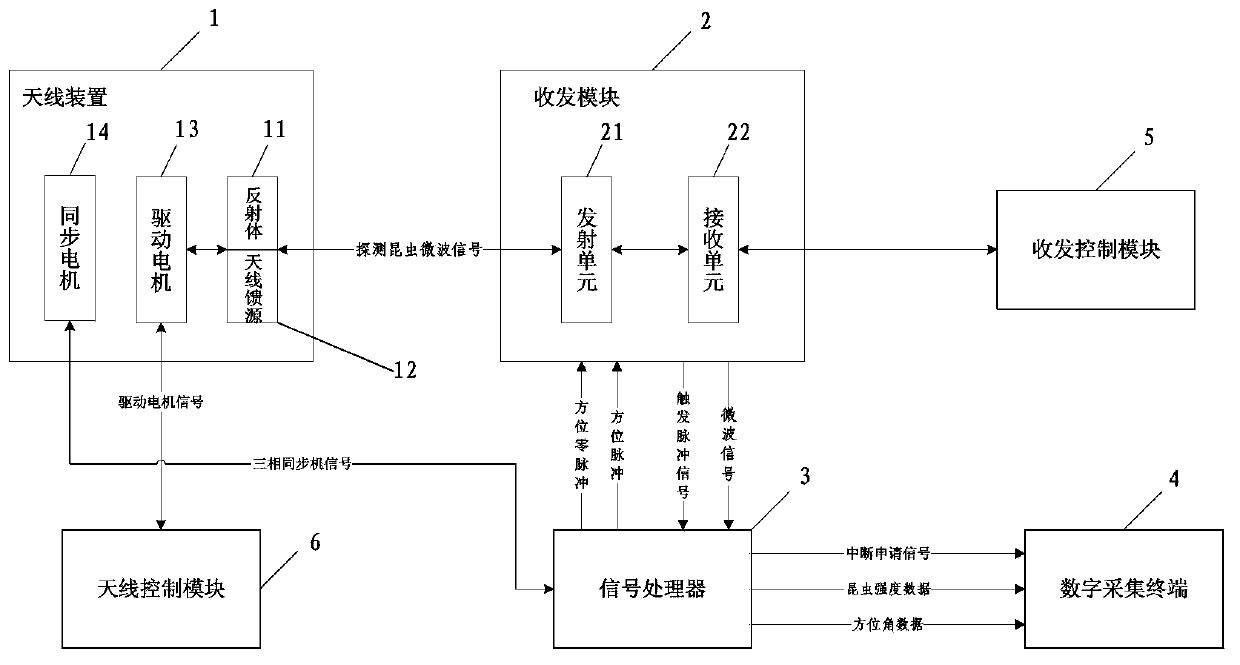

Vertical monitoring insect radar detection system and detection method

The invention discloses a vertical monitoring insect radar detection system, which is characterized by comprising an antenna device, a receiving and sending module, a signal processor and a digital collection terminal, wherein the antenna device is used for sending insect detection microwave signals and receiving microwave signals reflected by insects, the receiving and sending module is used for sending the insect detection microwave signals through the antenna device and carrying out amplification processing on the insect microwave signals received by the antenna device, the signal processor is used for receiving signals subjected to the amplification processing by the receiving and sending module and carries out conversion and processing to obtain insect intensity data, the azimuth angle data is obtained through the antenna device, and the data collection terminal is used for analyzing and calculating the obtained insect intensity data and the azimuth angle data to obtain the insect space distribution and time information. The vertical monitoring insect radar detection system and the detection method provided by the invention are used for developing seasonal long-period automatic monitoring of great migratory pests for crops in China, and the real-time monitoring and the early-stage early warning on the great migratory pests can be realized.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI +1

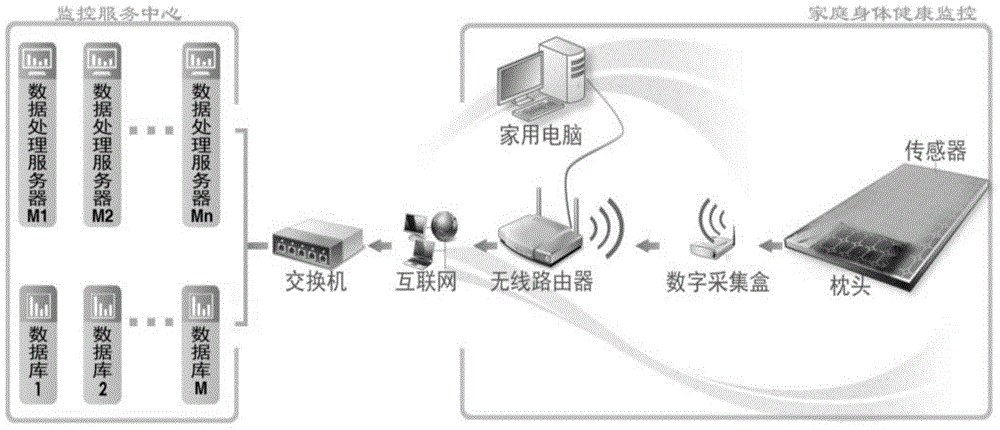

Human health sleep type remote monitoring and serving system

ActiveCN105212899AAct as a health guardIncrease exerciseDiagnostic recording/measuringSensorsEngineeringHuman health

The invention discloses a human health sleep type remote monitoring and serving system which comprises sensors, a digital collection box and a monitoring and serving center. The sensors include a weight sensor, a temperature sensor, a humidity sensor, a vibration sensor and a voice sensor which are distributed in a bed and a pillow of a monitored person, the digital collection box comprises a multiway switch, a signal conditioning circuit, an analog-digital conversion circuit, a processor, a storer and an interface circuit, the sensors are connected with the multiway switch which is connected with the signal conditioning circuit, the signal conditioning circuit is connected with the analog-digital conversion circuit, the analog-digital conversion circuit, the storer and the interface circuit are all connected with the processor, and the interface circuit and the monitoring and serving center are connected in a wired and / or wireless manner. By the human health sleep type remote monitoring and serving system, health conditions of middle-aged and elderly people can be monitored for a long time, suggestions on healthcare, disease prevention and timely treatment receiving and body alarming can be provided to users, and product and technology support is provided for health concept and practice of prevention before disease onset, treatment before disease onset and timely treatment receiving after disease onset.

Owner:四川远邦益安科技有限公司

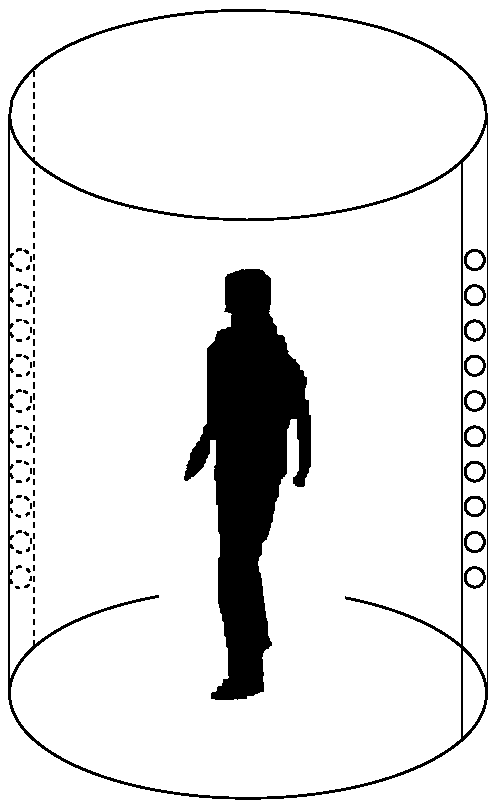

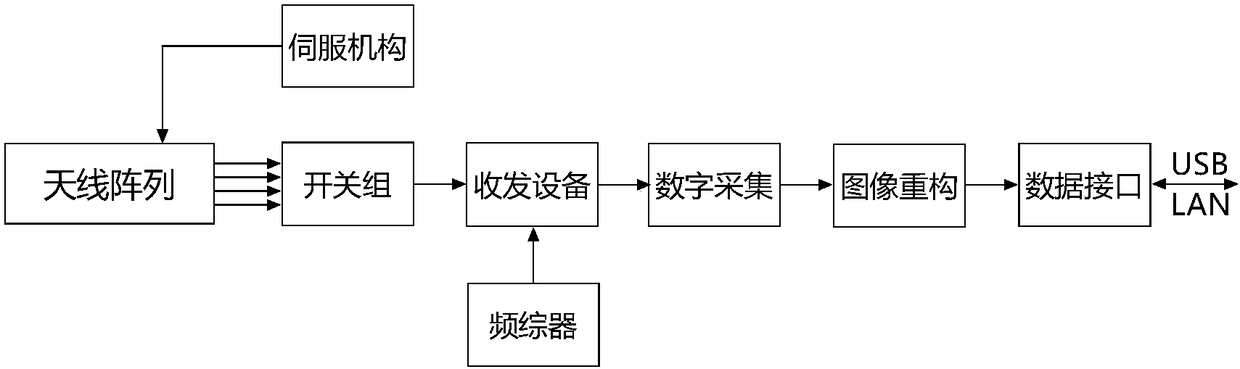

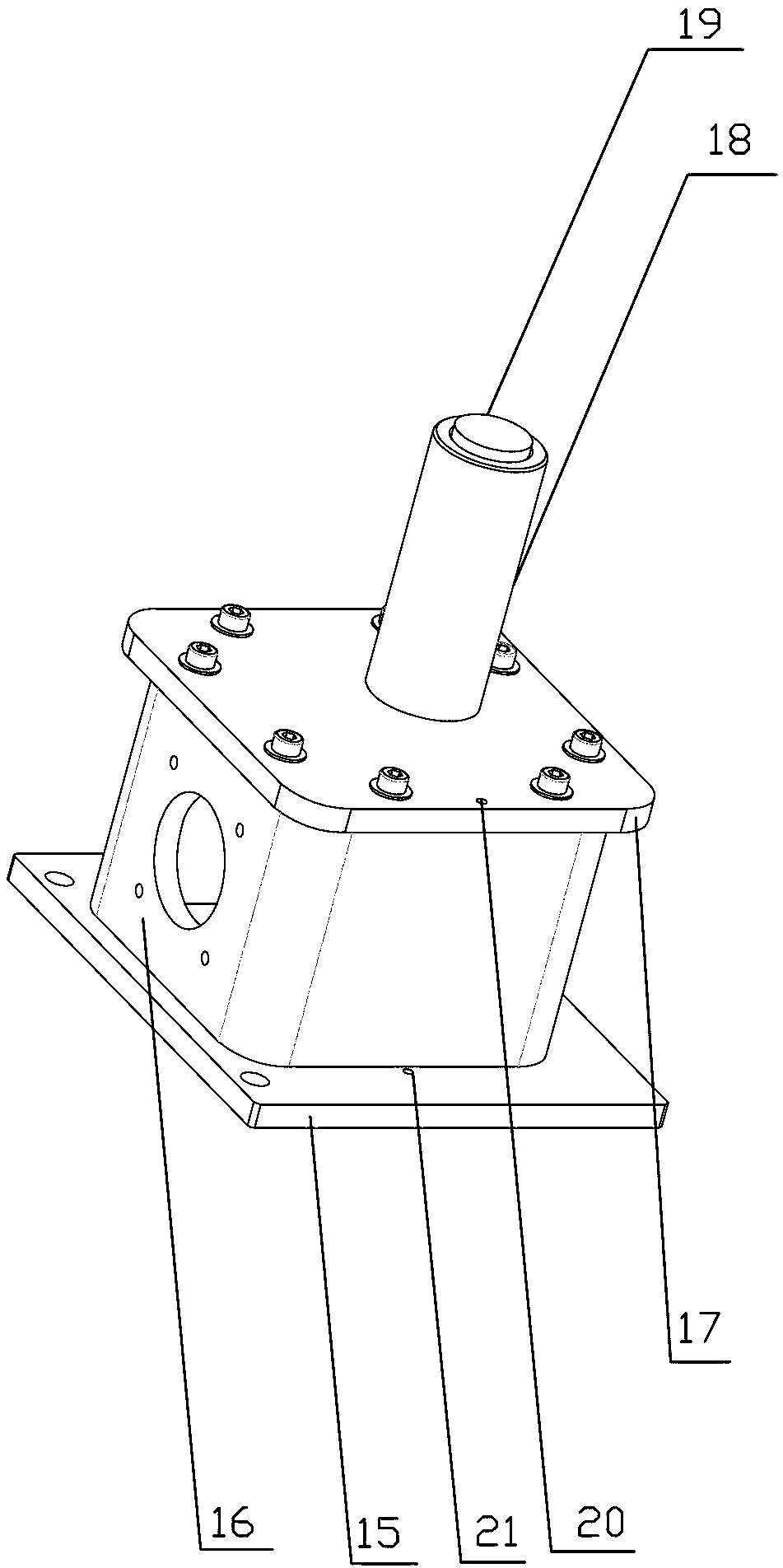

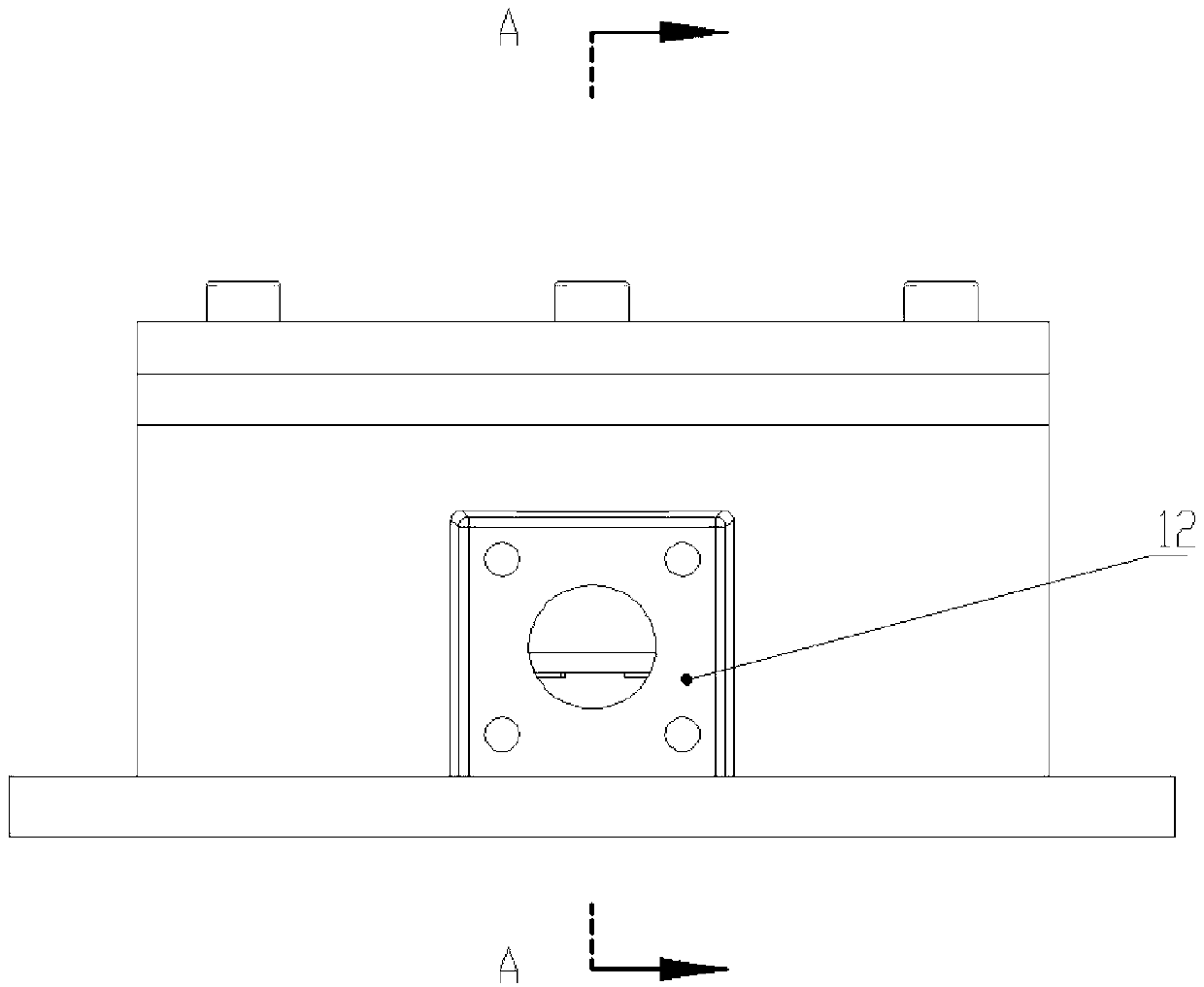

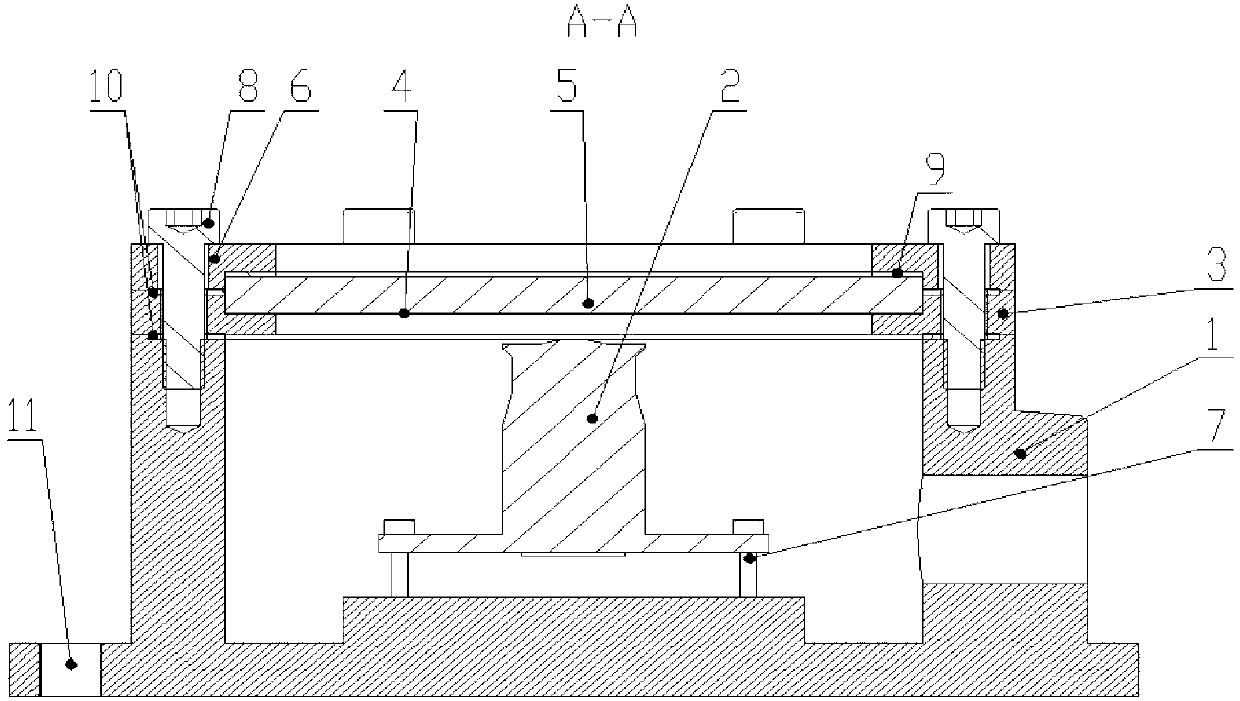

Foreign matter detection system based on millimeter-wave radar

InactiveCN108519623AHigh resolutionImprove performanceDetection using electromagnetic wavesRadio wave reradiation/reflectionRapid imagingForeign matter

The present invention discloses a foreign matter detection system based on a millimeter-wave radar. The system comprises: a millimeter-wave receiving and dispatching module, an antenna array module, adigital collection module and an image reconstruction module. The digital collection module receives signals output by the millimeter-wave receiving and dispatching module and processes the signals;and the image reconstruction module receives signals output by the digital collection module and performs rapid imaging processing to obtain real-time images of a detected scene. According to the scheme, the foreign matter detection system of the rapid and high-resolution millimeter-wave radar is developed, can be arranged at entrances of important places such as an airport, a wharf and the like for security check and can perform accurate detection of metal hazardous articles (such as cutters, guns and the like) and ceramic hazardous articles (such as explosive) hidden on people's bodies. Thereceiving and dispatching device of the millimeter-wave receiving and dispatching module, the switching group and the antenna array module are designed to allow the foreign matter detection system toachieve the optimal performances.

Owner:北博(厦门)智能科技有限公司

Sun position detection device and method

InactiveCN103217141AAvoid high demandsExtended TrackingAngle measurementControl using feedbackDigital collectionsControl signal

The invention discloses a sun position detection device and method. The device comprises a base, a shell and an upper cover; the shell, the upper cover and the base form a cavity; a camera for collecting solar image is arranged on the base in the cavity; and the upper cover comprises surrounding shading part and a transmitting part located in the center. The invention has the following advantages: (1) the digital camera avoids the high requirements of silicon cell on light source, so that the detection angle (field angle) changes with the light source to a desired size to expand the tracking range on the sun and improve the tracking efficiency; (2) a CCD sensor and a COMS sensor can identify the photos by domains to remove the interference image and obtain a real image of the sun, thereby greatly increasing the tracking precision; and (3) the control signal is output through a way that a single chip microcomputer collects photos and conducts operation analysis on the photo, and the digital collection process overcomes the problem of large error of simulation acquisition.

Owner:DALIAN GREAT OCEAN NEW ENERGY DEV +1

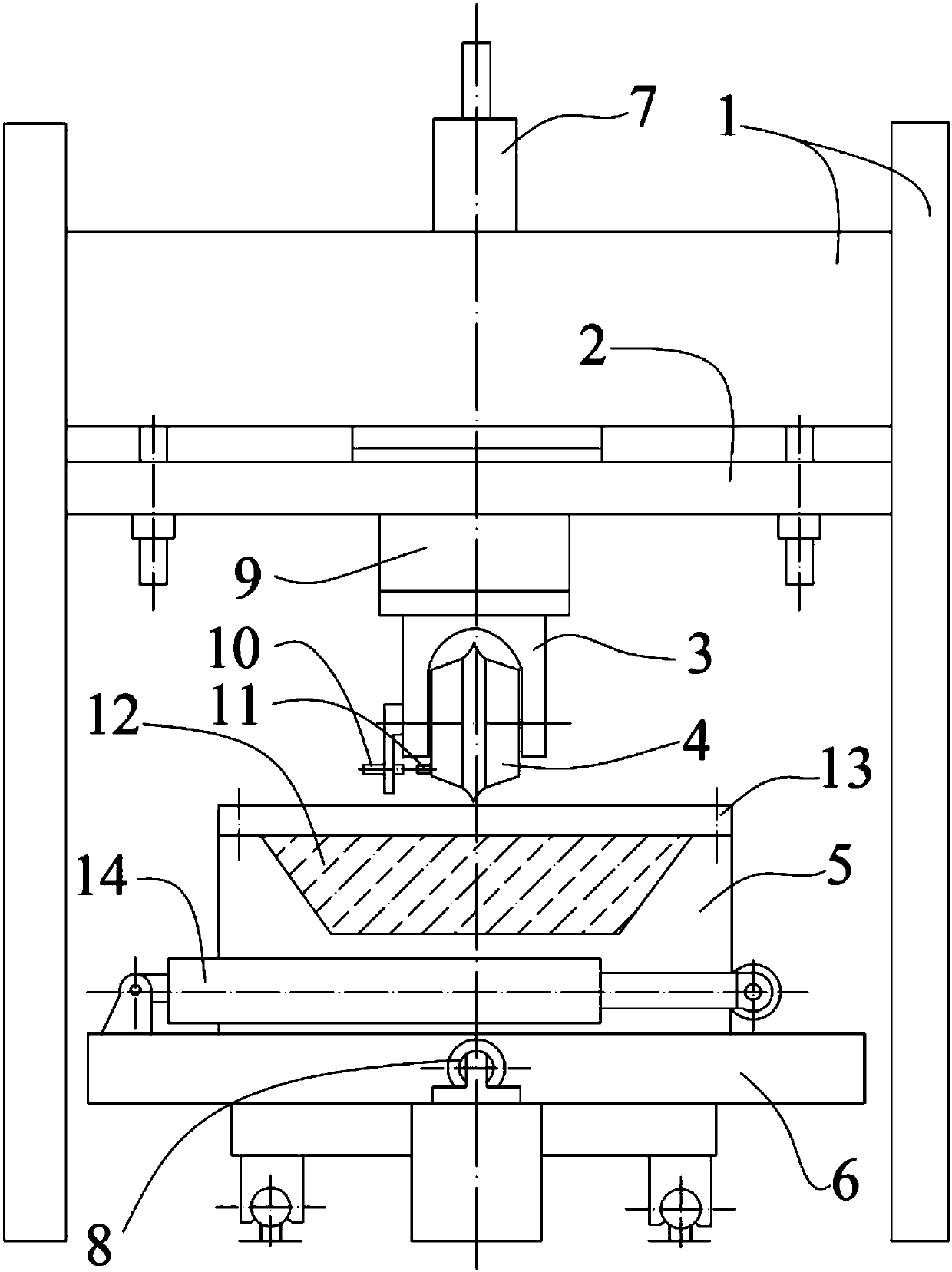

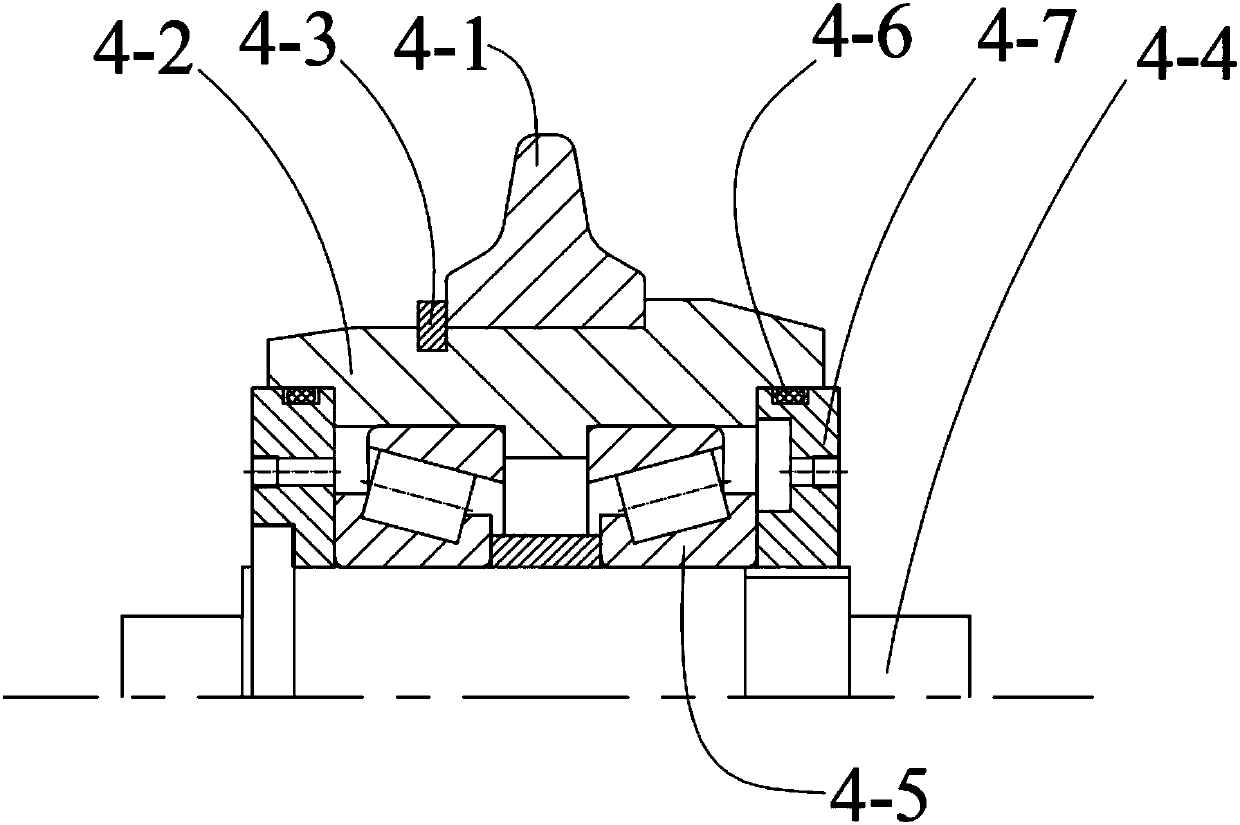

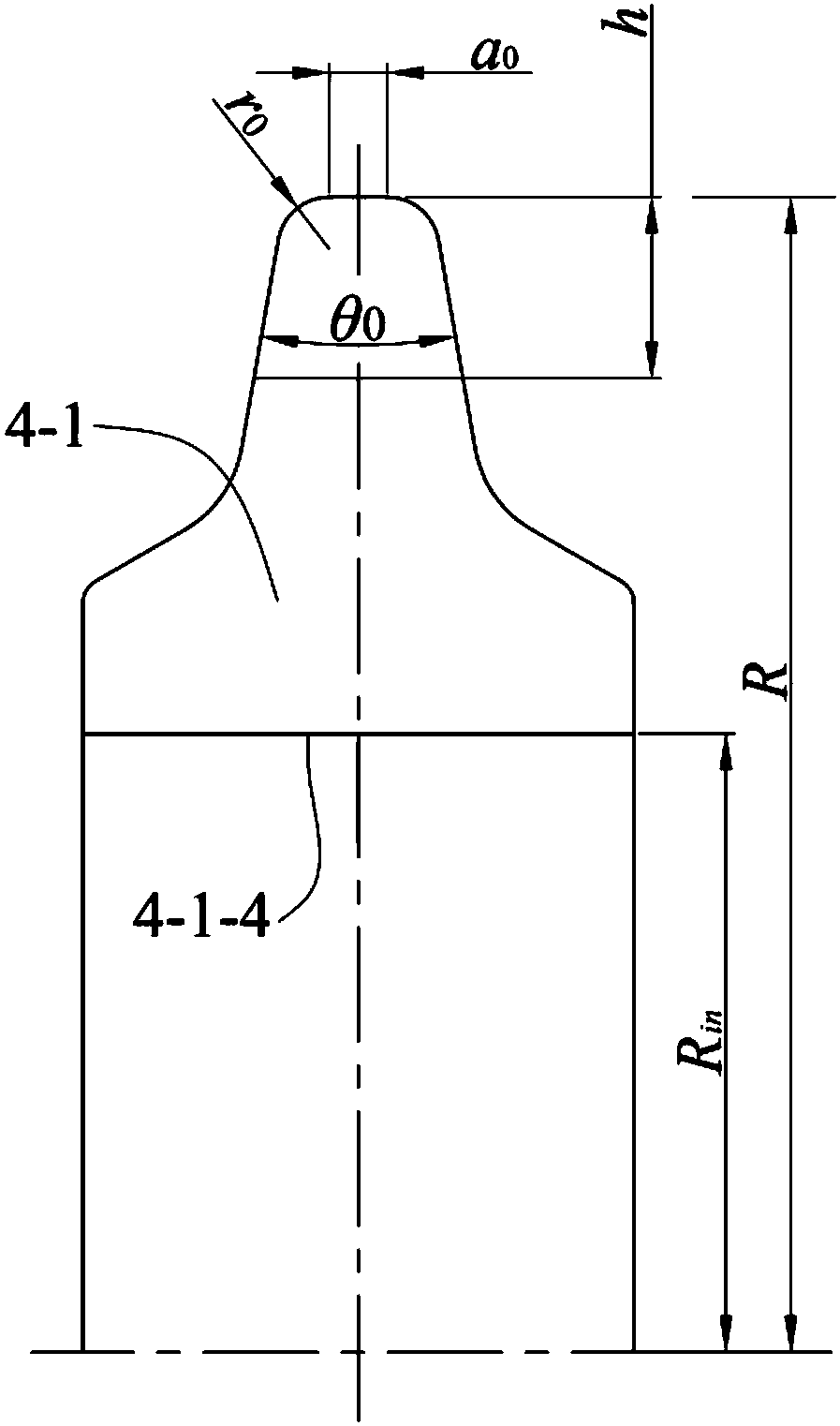

Cutter ring and cutter body matching surface positive pressure test system and test method of hobbing cutter

PendingCN108036886AExtended service lifeAvoid the risk of scratch damageApparatus for force/torque/work measurementStable stateHobbing

The invention relates to a test system and a test method capable of being used for testing the positive pressure on the cutter ring and cutter body matching surface in the hobbing cutter hobbing rockbreaking process in real time. The system comprises a digital collecting instrument, a hobbing cutter, an electric eddy current displacement sensor, an industrial computer and a pressure sensor, wherein the groove is locally formed in the matching surface of the cutter ring and / or the cutter body, so that a space gap for accommodating the pressure sensing region of the pressure sensor is formed inthe matching surface; one surface of the pressure sensing region is fixedly connected with one surface of the space gap; in the initial stable state, the pressure sensing region has a given tiny initial vertical extrusion deformation quantity Delta 0; the digital collection instrument can collect the output signals of a three-direction force sensor, a pressure sensor and an electric eddy currentdisplacement sensor in real time and transmits the signals to the industrial computer. The test system and the test method solve the problem of limitation of real-time monitoring measurement difficulty of the positive pressure on the cutter ring and cutter body matching surface during the hobbing cutter hobbing rock breaking.

Owner:XIANGTAN UNIV

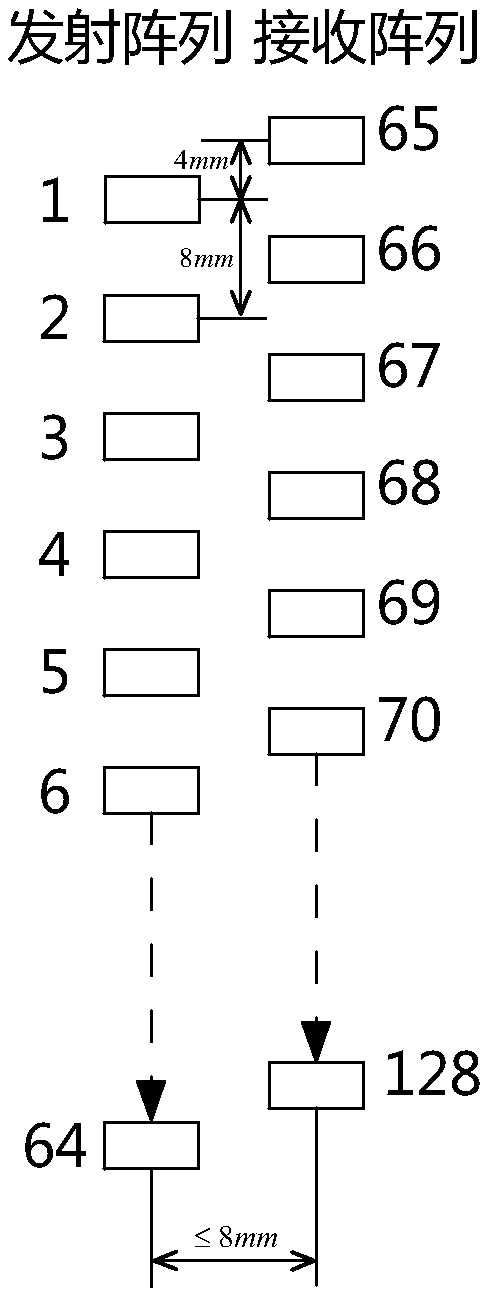

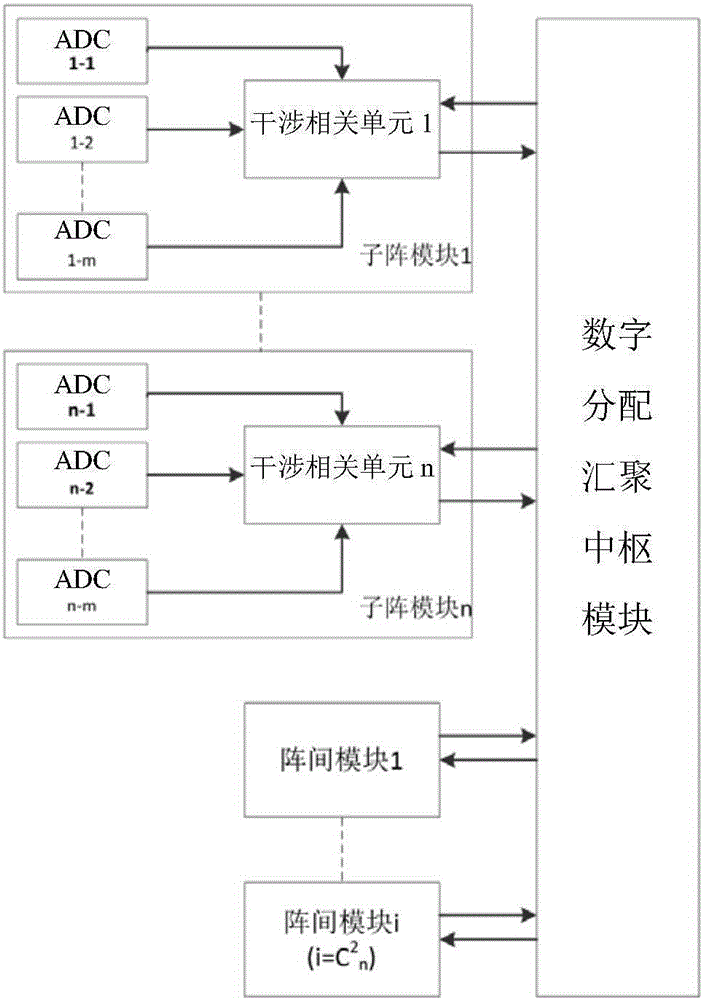

Synthetic-aperture-radiometer-based distributed digital interferometer system

ActiveCN106556832AAvoid redesignSimple structureRadio wave reradiation/reflectionComplete dataDigital collections

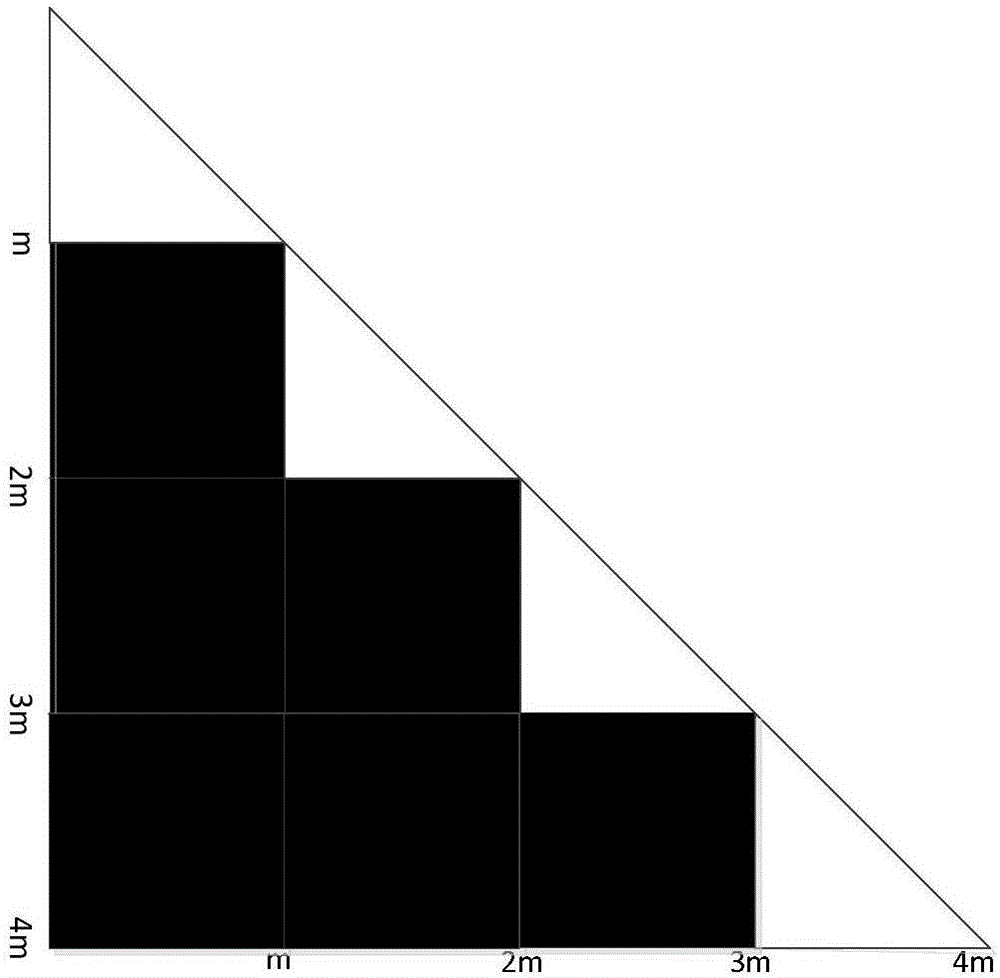

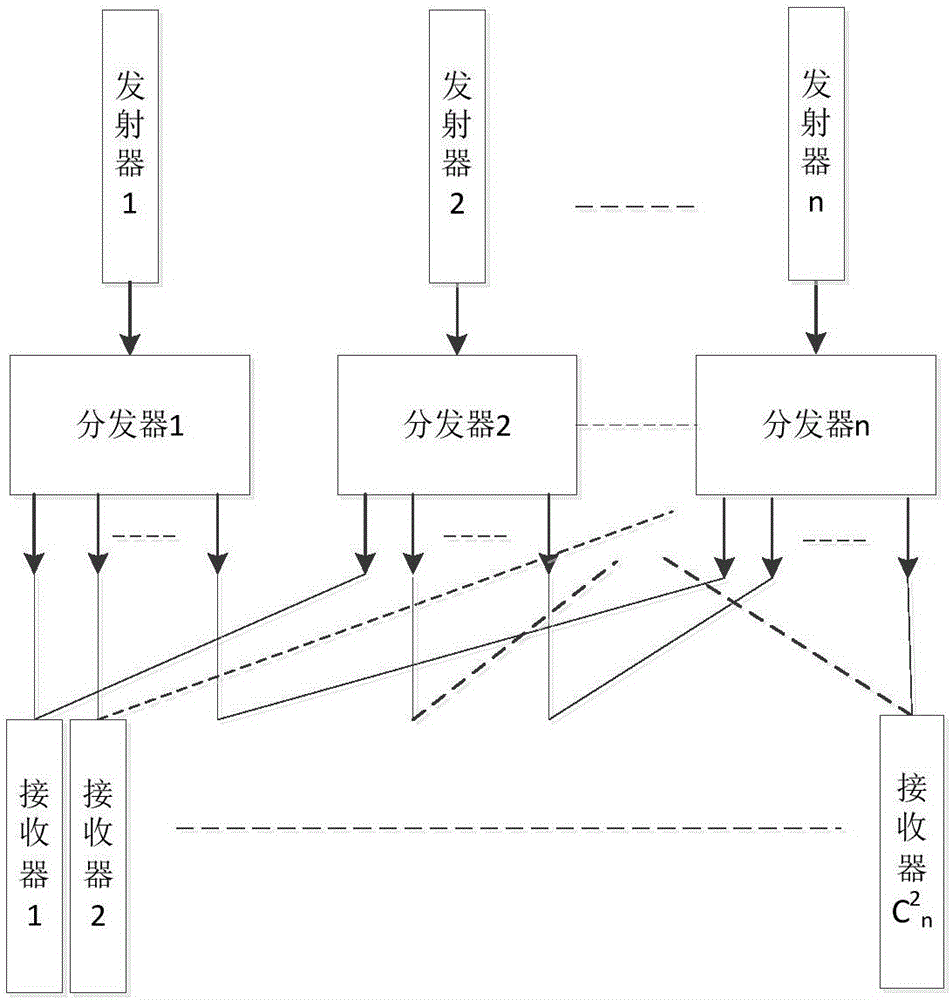

The invention provides a synthetic-aperture-radiometer-based distributed digital interferometer system. The system comprises a plurality of sub array modules, a plurality of inter-array modules, and a digital distribution aggregation hub module. According to the distributed digital interferometer system, all channels in a radiometer receiver are distributed to all sub array modules according to the set number; all the sub array modules carry out digital collection of distributed data in all channels and complete data autocorrelation in channels and data cross-correlation calculation between channels; the digital distribution aggregation hub module distributes the digital signals collected by the sub array modules combined in pairs to all the inter-array modules and receives data correlation calculation results of the sub array modules and the inter-array modules; and the inter-array modules complete data cross-correlation calculation of channels in pairs between the sub array modules. Using the system provided by the invention, the massive interference correlation calculation can be split into multiple groups of intra-sub-array correlation and inter-array correlation calculation, so that the system design is simplified and the system structure is optimized.

Owner:NAT SPACE SCI CENT CAS

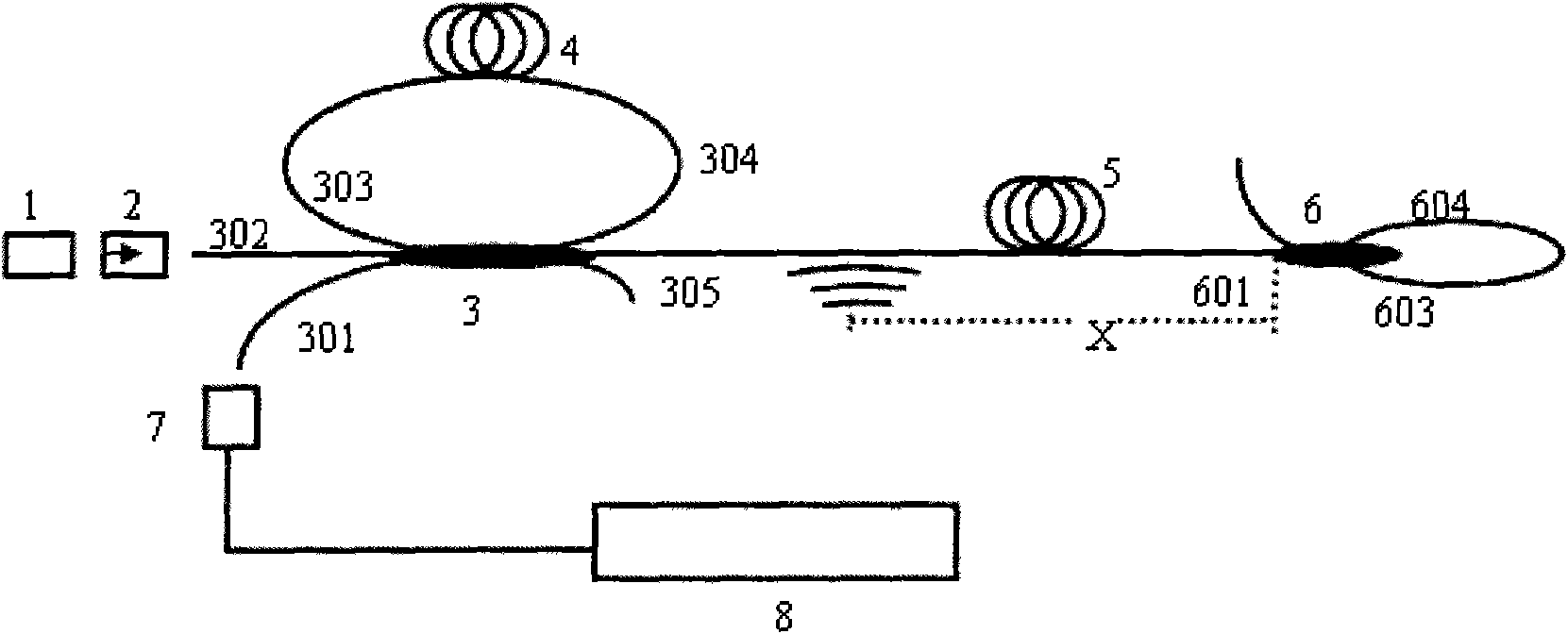

Distributed optical fiber sagnac positioning sensor inhibiting dead zone of sensor

InactiveCN101581586ALow insertion lossInhibition Sensing Dead ZoneConverting sensor output opticallySignal-to-noise ratio (imaging)Digital collections

The invention relates to a distributed optical fiber sagnac positioning sensor inhibiting the dead zone of a sensor, which is characterized by comprising a first optical fiber coupler and a second optical fiber coupler; the light-inlet port of the first optical fiber coupler is a second port, and the light-outlet port of the first optical fiber coupler is a first port, a third port, a fourth port, a fifth port and a sixth port; the third and the fourth ports of the first optical fiber coupler are mutually connected by a delay optical fiber, a photoelectric detection unit is arranged in front of the first port of the first optical fiber coupler, and the output signal of the photoelectric detection unit is switched in an A / D conversion digital collection card which is electrically connected with a computer; the sensor also comprises a sensing optical fiber and the second optical fiber coupler; and a reference light source is arranged in front of the second port of the first optical fiber coupler, and an optoisolator is arranged between the reference light source and the second port. The invention reduces insertion consumption, and the delay of optical fiber length by reasonable selection can not only inhibit sensing dead zone in the sensing optical fiber, but also eliminate pseudo-zero frequency points appearing in signal demodulation, and improve the signal-to-noise ratio.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

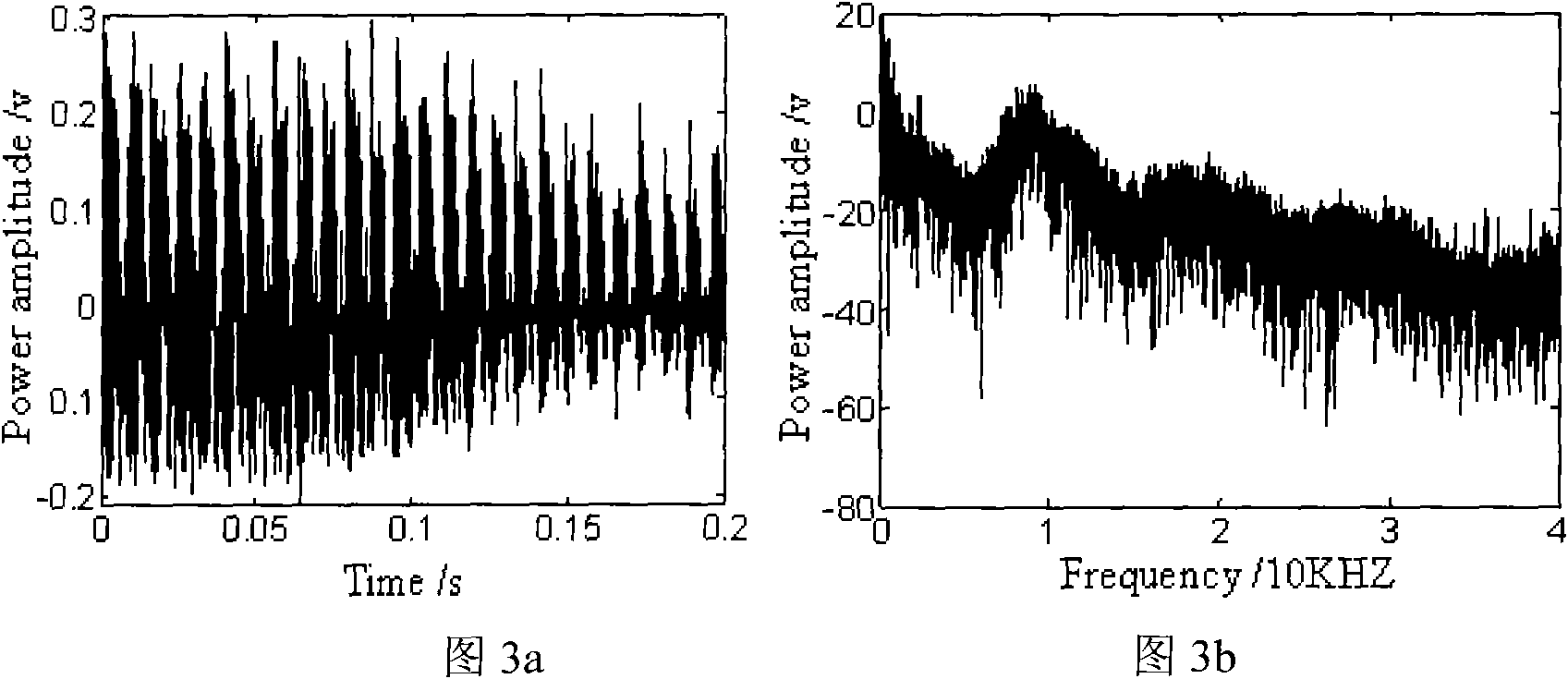

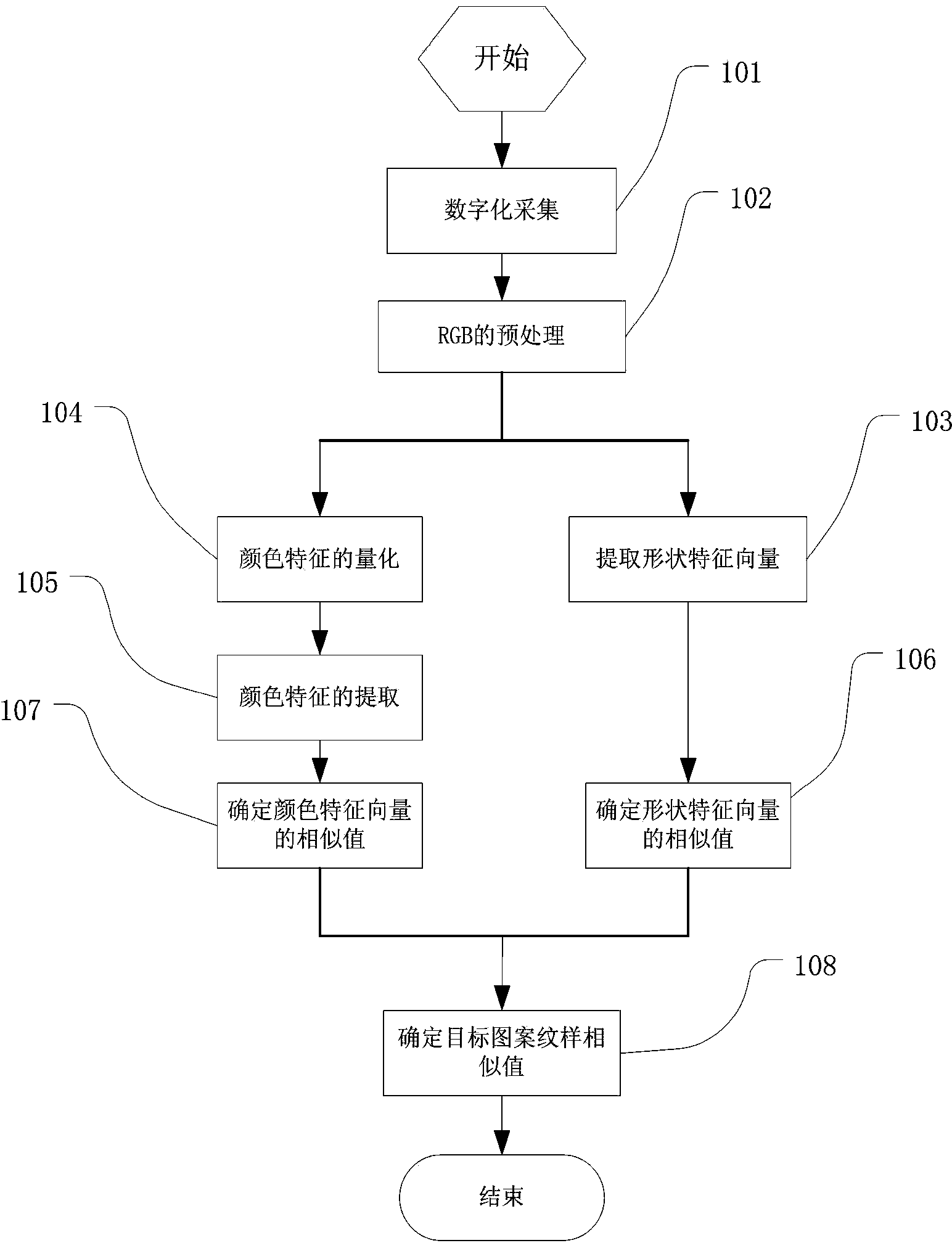

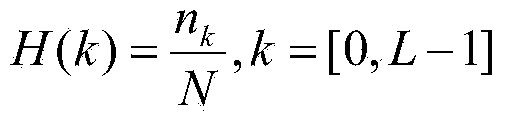

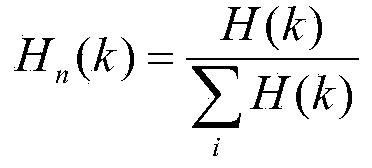

Method for recognizing patterns of blueprint cloth

InactiveCN103871084AIncrease success rateGood image retrievalImage analysisSpecial data processing applicationsFeature vectorFeature extraction

The invention provides a method for recognizing patterns of blueprint cloth. The method includes the steps that digital collection of target design patterns is carried out, RGB preprocessing is conducted on the collected target design patterns, after RGB preprocessing is completed, a design pattern to be detected is obtained for conducting color feature quantization and color feature extraction, and after RGB preprocessing is completed, the design pattern to be detected is obtained for extracting a shape feature vector; the similarity value of an extracted color feature vector and the color feature vector of a standard design pattern is determined, and the similarity value of the extracted shape feature vector and the shape feature vector of the standard design pattern is determined; a corresponding searching weight number is obtained by integrating the weight number of color features and the weight number of shape features, and the similarity of the target design patterns is determined according to the searching weight number. The multi-feature search method which is mainly dominated by the color features and supplemented by the shape features overcomes the defect that the success rate of single-feature search is low, and compared with a single-feature search method, the method has better effect.

Owner:NANTONG AGRI COLLEGE +1

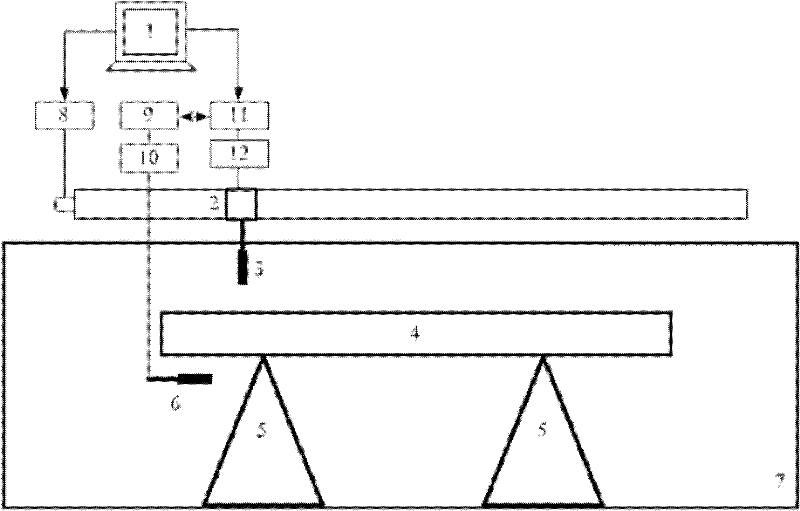

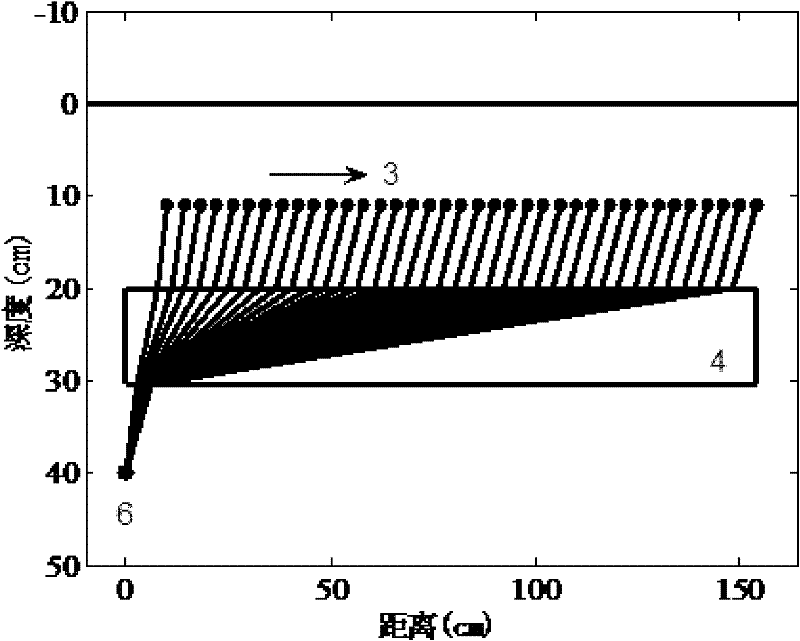

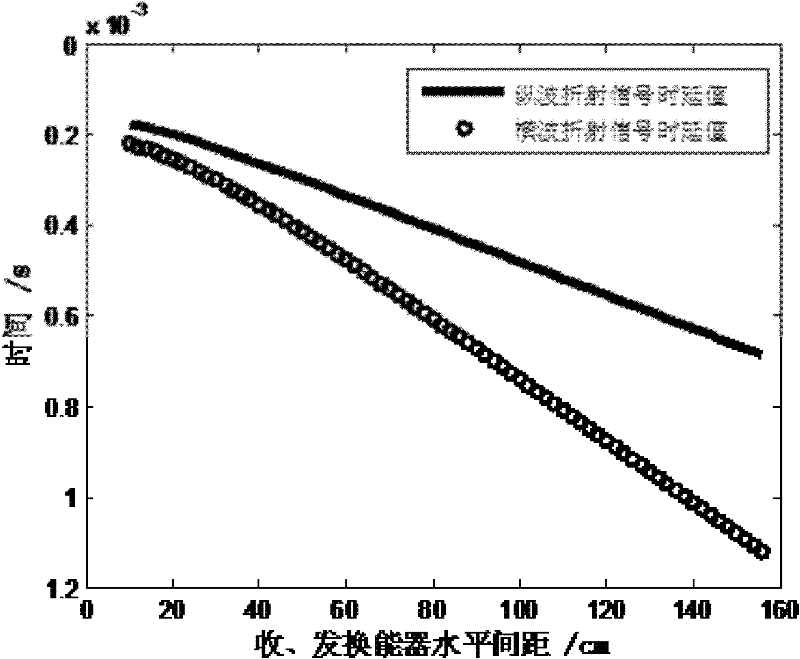

Acoustic velocity measurement device and method for large-size elastic material

InactiveCN102589673AAvoid destructionMeet actual needsAnalysing solids using sonic/ultrasonic/infrasonic wavesVibration measurement in fluidMeasurement deviceData acquisition

The invention provides an acoustic velocity measurement device and method for a large-size elastic material. The acoustic velocity measurement device comprises a system control computer, a movable rack, a receiving hydrophone, a wide-band and high-frequency transmission transducer, a movable rack controller, a signal source, a power amplifier, a digital collection card and a measurement amplifier, wherein the signal source, the power amplifier and the wide-band and high-frequency transmission transducer are electrically connected in sequence; the system control computer, the data collection card, the measurement amplifier and the receiving hydrophone are electrically connected in sequence, and the synchronous end of the data collection card is electrically connected with the synchronous end of the signal source; the system control computer, the movable rack controller and the movable rack are electrically connected in sequence; a material to be measured is horizontally placed in a tiltable bracket in a water pool, the wide-band high-frequency transmission transducer is placed under the material to be measured, and the receiving hydrophone is placed on the material to be measured and fixed on the movable rack. According to the measurement device, the accuracy of the measurement result is ensured. The acoustic velocity in the large-size elastic material obtained by the method is in accordance with the actual situation.

Owner:HARBIN ENG UNIV

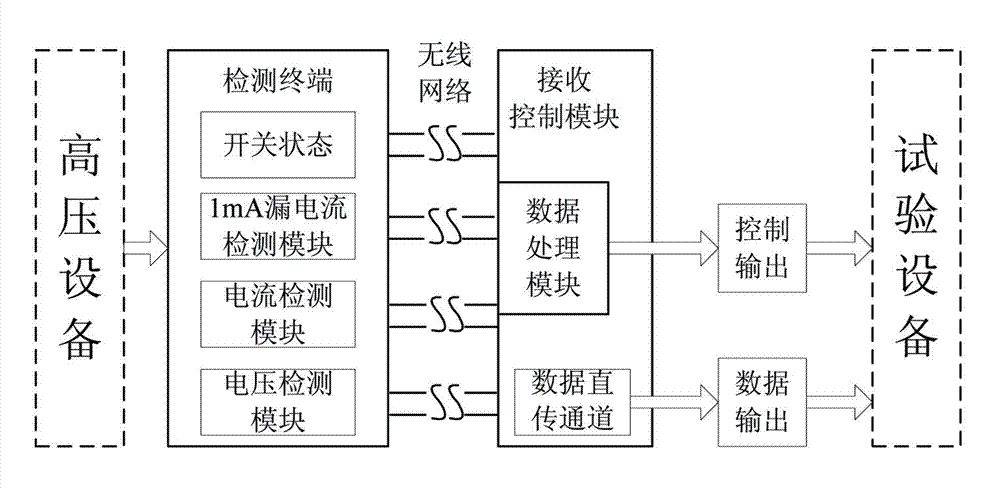

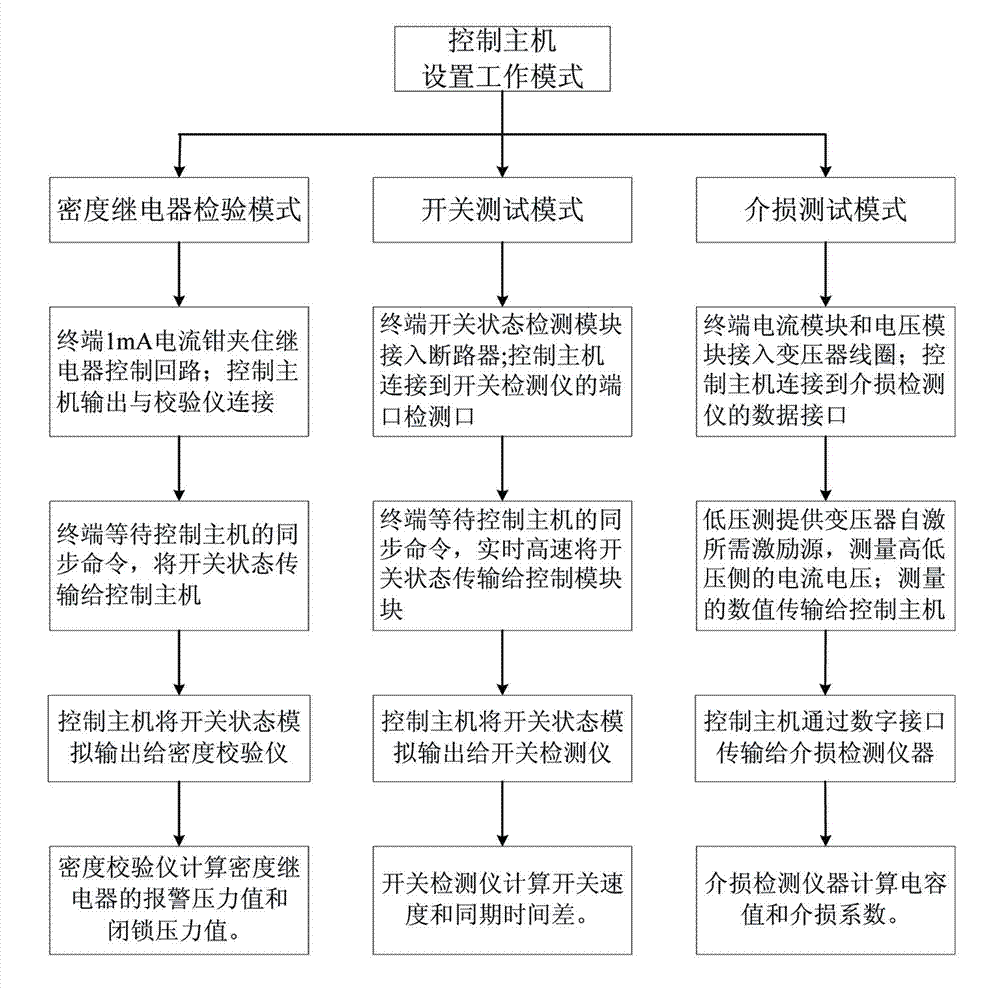

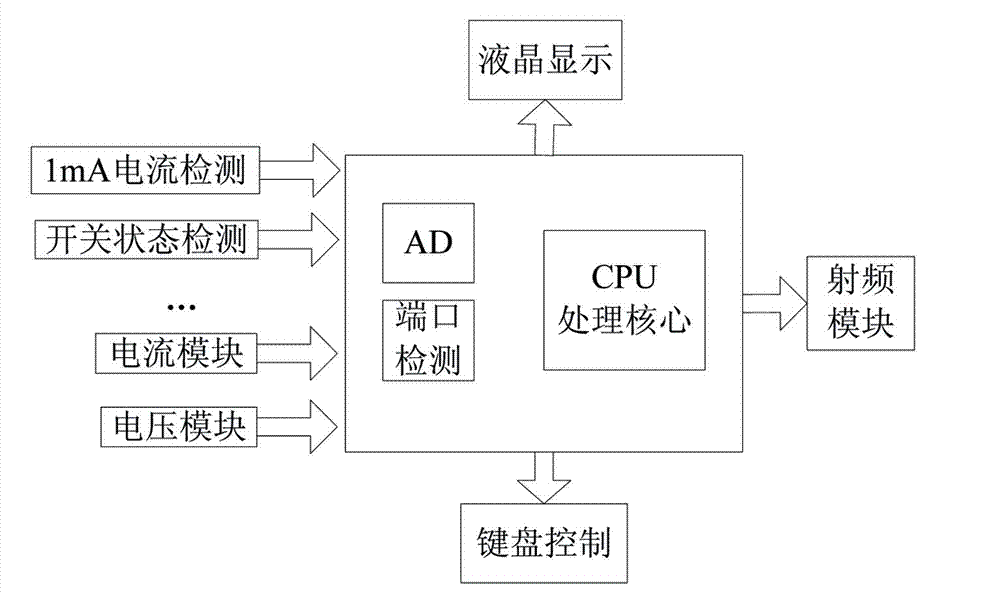

Combined device for contactless type measurement through electrical testing equipment and application thereof

ActiveCN103076560AExtended service lifeAvoid attenuationTransmission systemsCurrent/voltage measurementMeasurement deviceDigital collections

The invention provides a combined device for contactless type measurement through electrical testing equipment and an application thereof. The combined device for the contactless type measurement is used for digitally collecting power equipment signals and further wirelessly transmitting the power equipment signals to the electrical testing equipment, and comprises one control host and multiple detection terminals, wherein the control host and the multiple detection terminals form a star network through the remote communication of a radio frequency module, so that the point-to-multipoint combined measurement device is formed; one end of the combined measurement device is connected with power equipment through the detection terminals; the other end of the combined measurement device is connected with the electrical testing equipment through the control host; and modules of the detection terminals are connected with the power equipment, so that the corresponding electrical test measurement is performed on the power equipment. Based on a contactless type sensing technique and a radio frequency technique, the device adopts a contactless type sensor technique to replace the traditional measurement way; through a networking technique, the digital collection and the transmission are realized; as the procedures of measurement, collection and the like are effectively separated, the working of workers in the risky areas is prevented; and therefore, the working efficiency is improved and the operation risk is lowered.

Owner:MAINTENANCE BRANCH OF STATE GRID CHONGQING ELECTRIC POWER +1

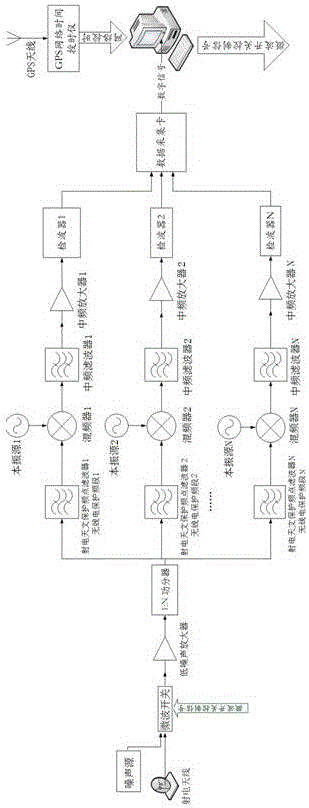

Superheterodyne solar radiometer system for radio astronomical protection frequency point

PendingCN106226594AReduce distractionsLarge dynamic rangeElectric devicesElectric power measurementDigital collectionsRadiometer

The invention discloses a superheterodyne solar radiometer system for a radio astronomical protection frequency point. The superheterodyne solar radiometer system comprises an analog receiver subsystem, a detection-digital collection subsystem, a calibration subsystem, a time frequency subsystem and a control subsystem, wherein the analog receiver subsystem is connected with the control subsystem via the detection-digital collection subsystem; the calibration subsystem and the time frequency subsystem are respectively connected with the control subsystem. The system has the advantages of less radio interference, large dynamic range, simple structure and the like, is applied to multi-point frequency solar radio flow precision observation, and effectively speculates a spatial weather event via observation data.

Owner:YUNNAN ASTRONOMICAL OBSERVATORY CHINESE ACAD OF SCI

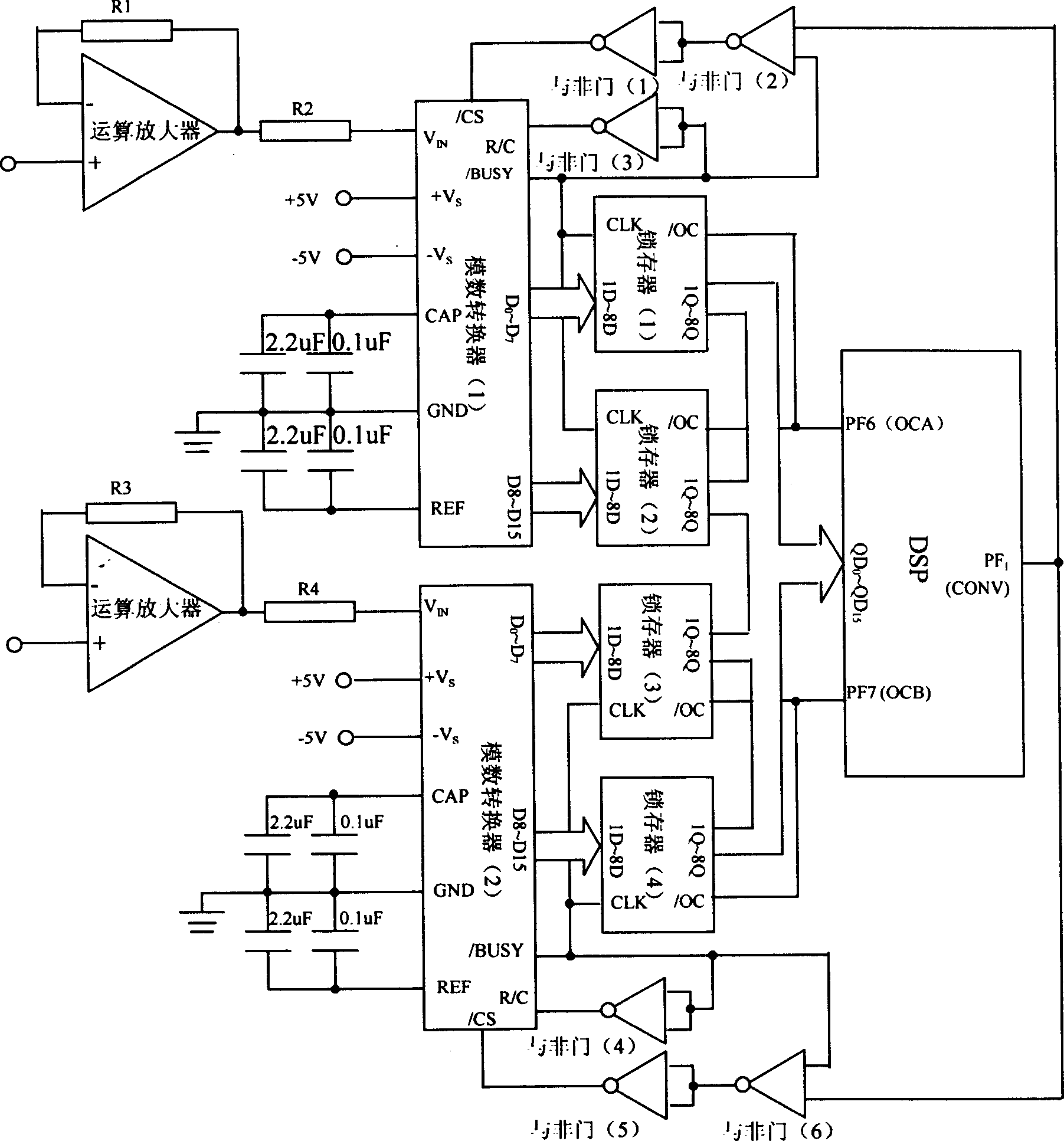

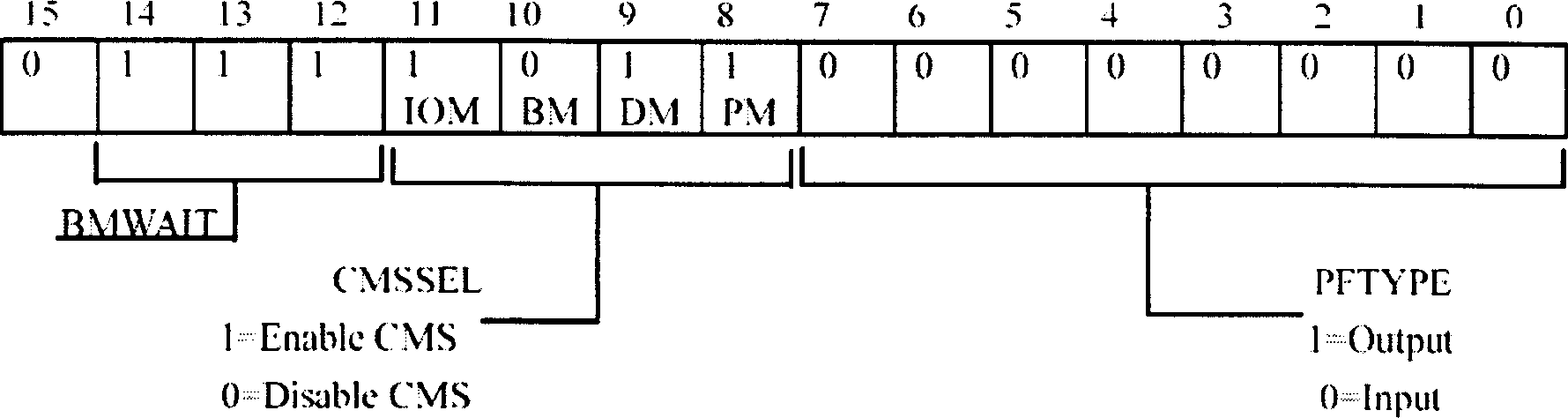

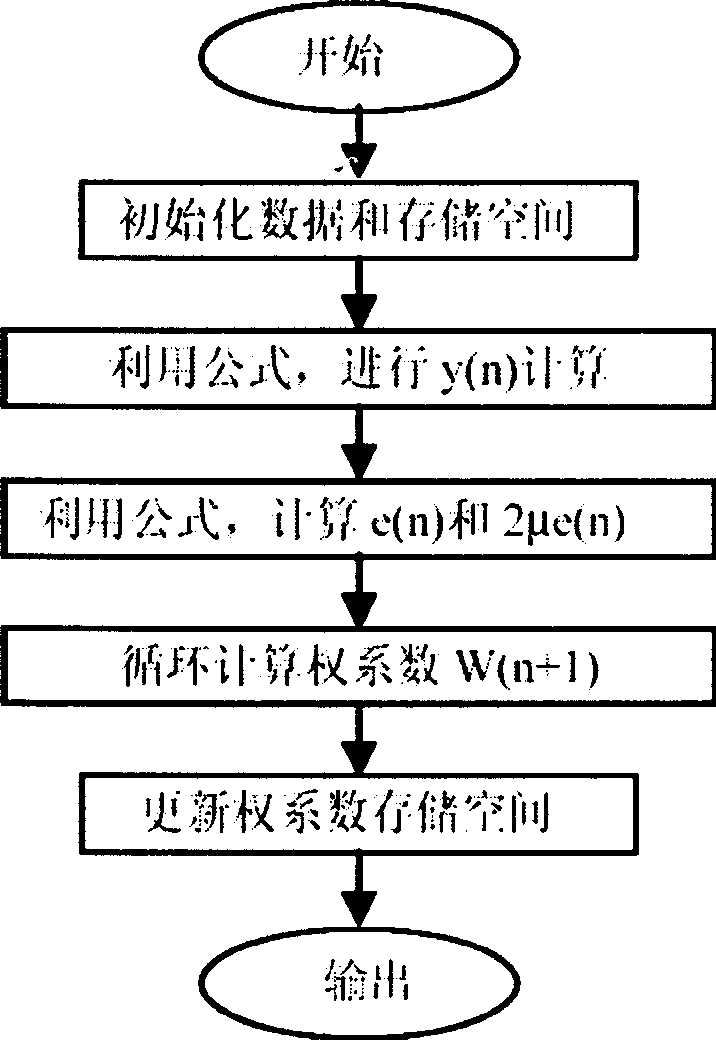

Photo signal digital collection module for electric power optical potential sensor

InactiveCN1434299AFulfil requirementsEliminate distractionsMeasurement using digital techniquesDigital signal processingAdaptive filter

The invention is a digital collection module of the optical signal of the electric power optical voltage snesor, adopting the two-way synchronous sampling asynchronous transmission mode and the self-adaptive filter to process the signal. Firstly make the sample signal pass through two-way amplifying circuit, then make the A / D conversion in two-way A / D converting circuit, the then use the latchingcircuit to latch it, and finally use the filter to process it in the DSP module in order to filter the noise mixed in the signal.

Owner:SHANGHAI JIAO TONG UNIV

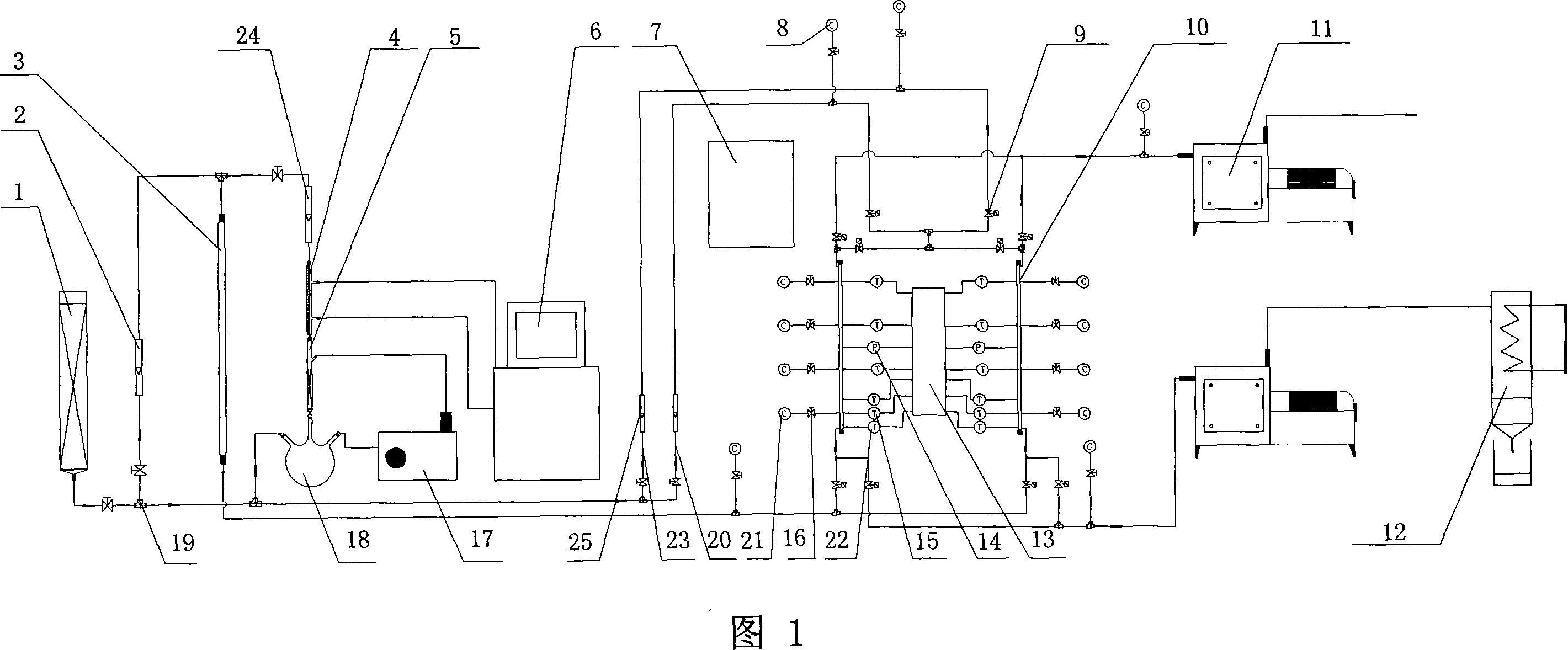

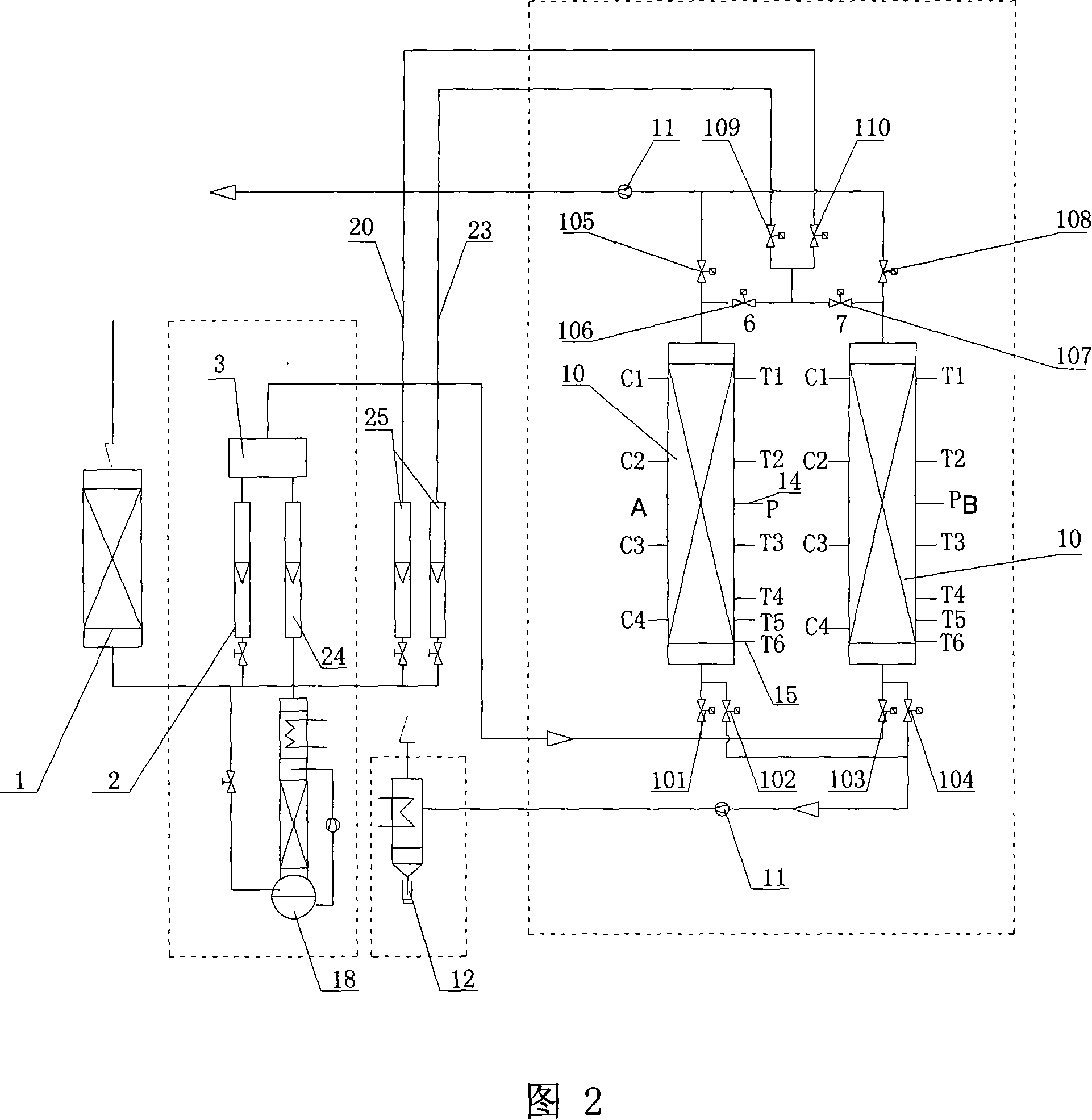

Multi-component organic-gas pressure-changing adsorption and realtime detection-control experiment device

InactiveCN101069802ANo pollutionSafe and reliable performanceDispersed particle separationDigital collectionsProduct gas

The present invention discloses a multicomponent organic gas pressure swing adsorption and real time test control experiment equipment. It is characterized by that the outlet place of its drying column is divided into three lines, first line is directly connected with gas inlet positioned in the upper end of pressure swing adsorption column; second line is connected with gas inlet of gas mixing column; and third line is connected with gas inlet of gas mixing column by means of organic gas generator and miniature packed column. The outlet of the gas mixing column is connected with gas inlet positioned in the lower end of the pressure swing adsorption column. The upper portion of every pressure swing adsorption column is equipped with three or more than three gas sampling units and temperature sampling units correspondent to said gas sampling units, its middle portion is equipped with a pressure sampling unit, and its lower end is equipped with two or more than two second temperature sampling units. The gas sampling unit is connected with a gas chromatograph and the pressure sampling unit and temperature sampling unit are connected with a temperature and pressure digital collection system.

Owner:CENT SOUTH UNIV

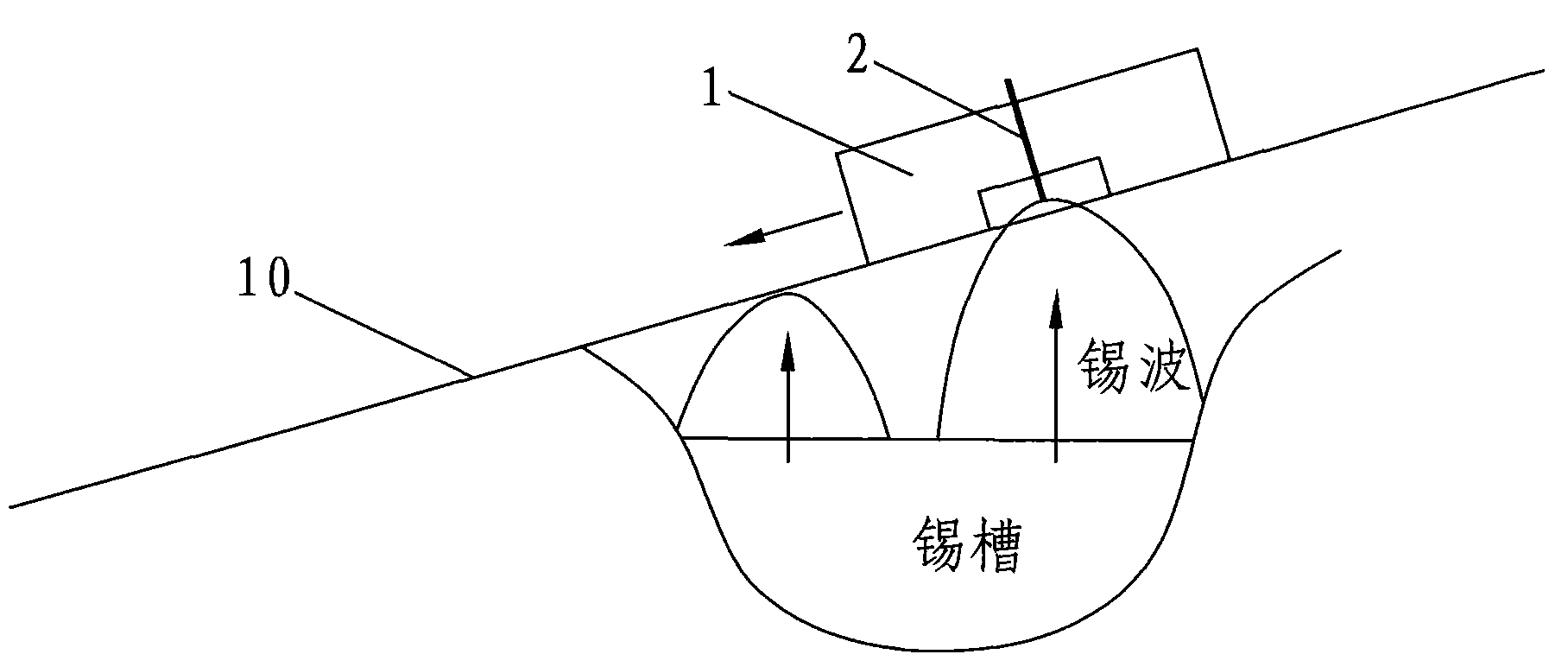

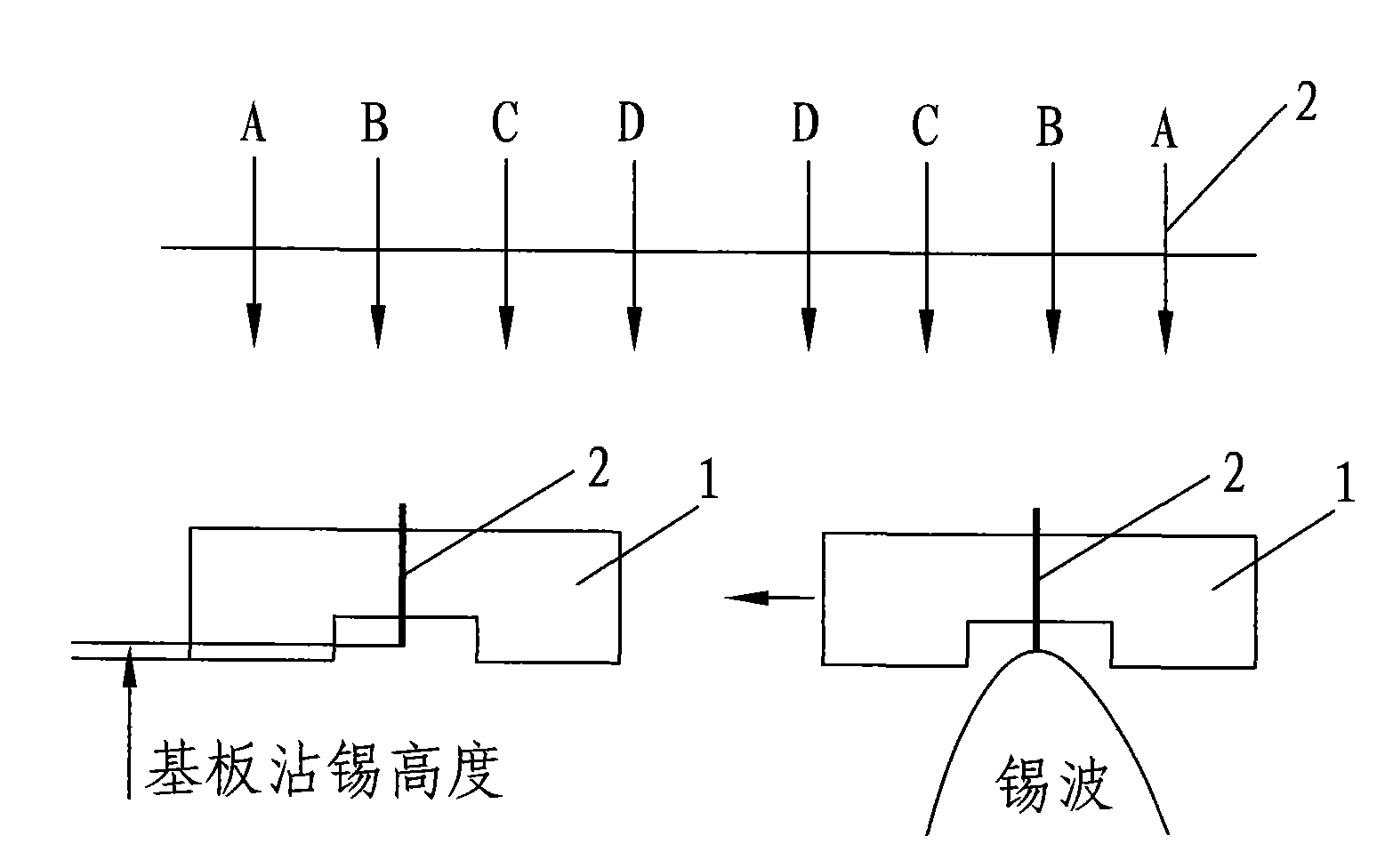

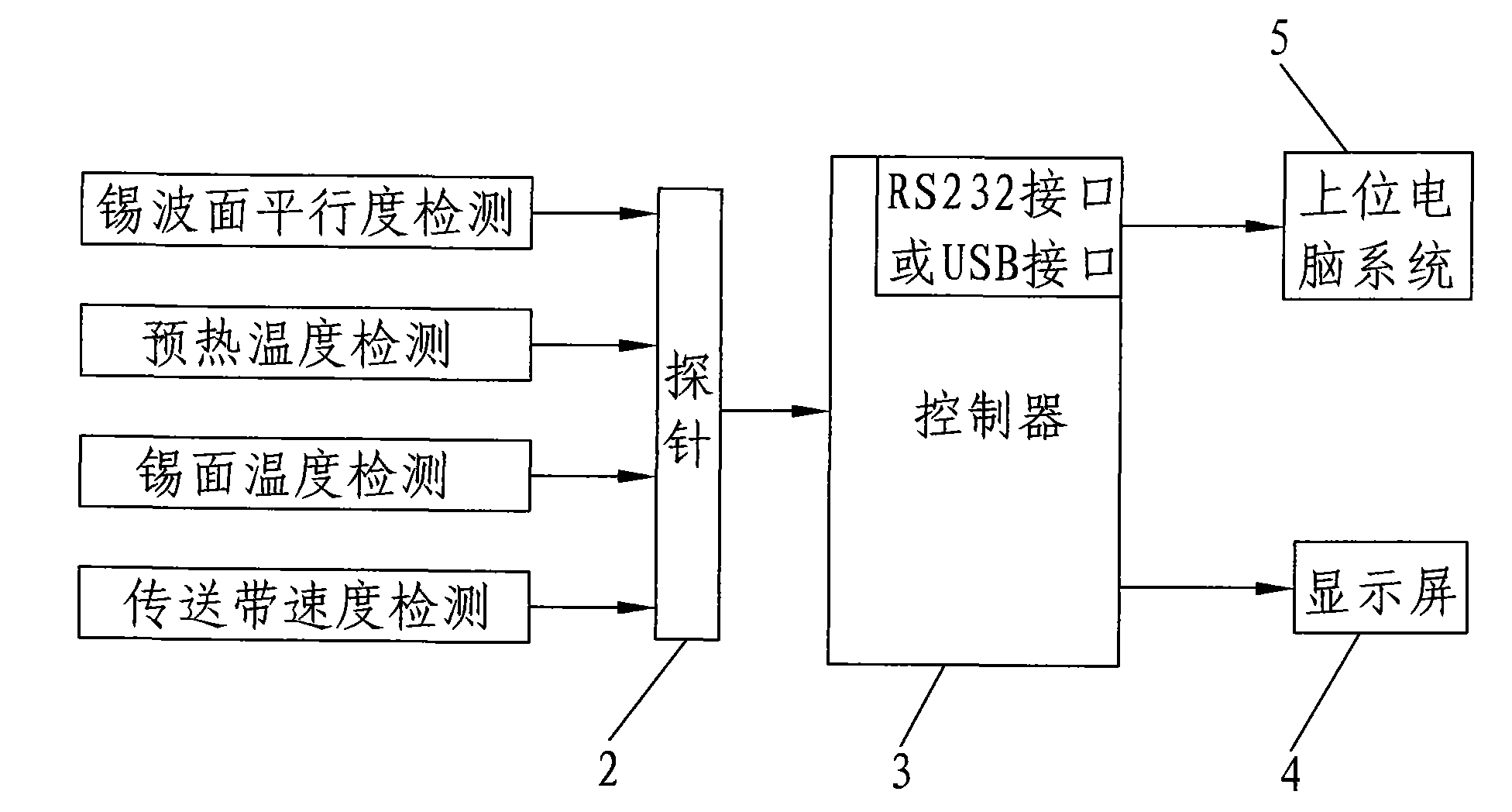

Method and system for detecting parameters of tinning furnace

InactiveCN101628353AEasy to operateNo safety hazardPrinted circuit assemblingSoldering auxillary devicesTinningDigital collections

The invention relates to the technical field of crest welders, in particular to a method and a system for detecting parameters of a tinning furnace. In the invention, a plurality of probes are distributed on a detecting smelting tool in a linear arranging mode, the detecting smelting tool moves along a conveying track of the tinning furnace, simultaneously the probes detect the temperature of each detecting point, and tin wave surface parallelism analysis is carried out on the time data of each probe contacting a tin wave surface by utilizing multi-point comparison, and then the shape of the tin wave surface is obtained by judging the compared results. The invention has the advantages that firstly, the tin wave surface parallelism detection is more improved compared with a traditional detection mode, and digital collection detection method is adopted so that the operation is more convenient without safety hazard, and the detection precision is also obviously improved; secondly, the whole detection process is automatically finished without the participation of maintenance personnel; thirdly, various detection data can be stored for a long period so as to be beneficial to analysis and processing; and fourthly, parameters of the temperature of each section, the parallelism of the tin surface, the welding speed, and the like in the tinning furnace can be comprehensively detected.

Owner:DELTA ELECTRONICS DONGGUAN

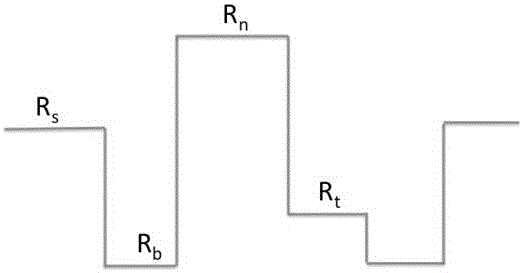

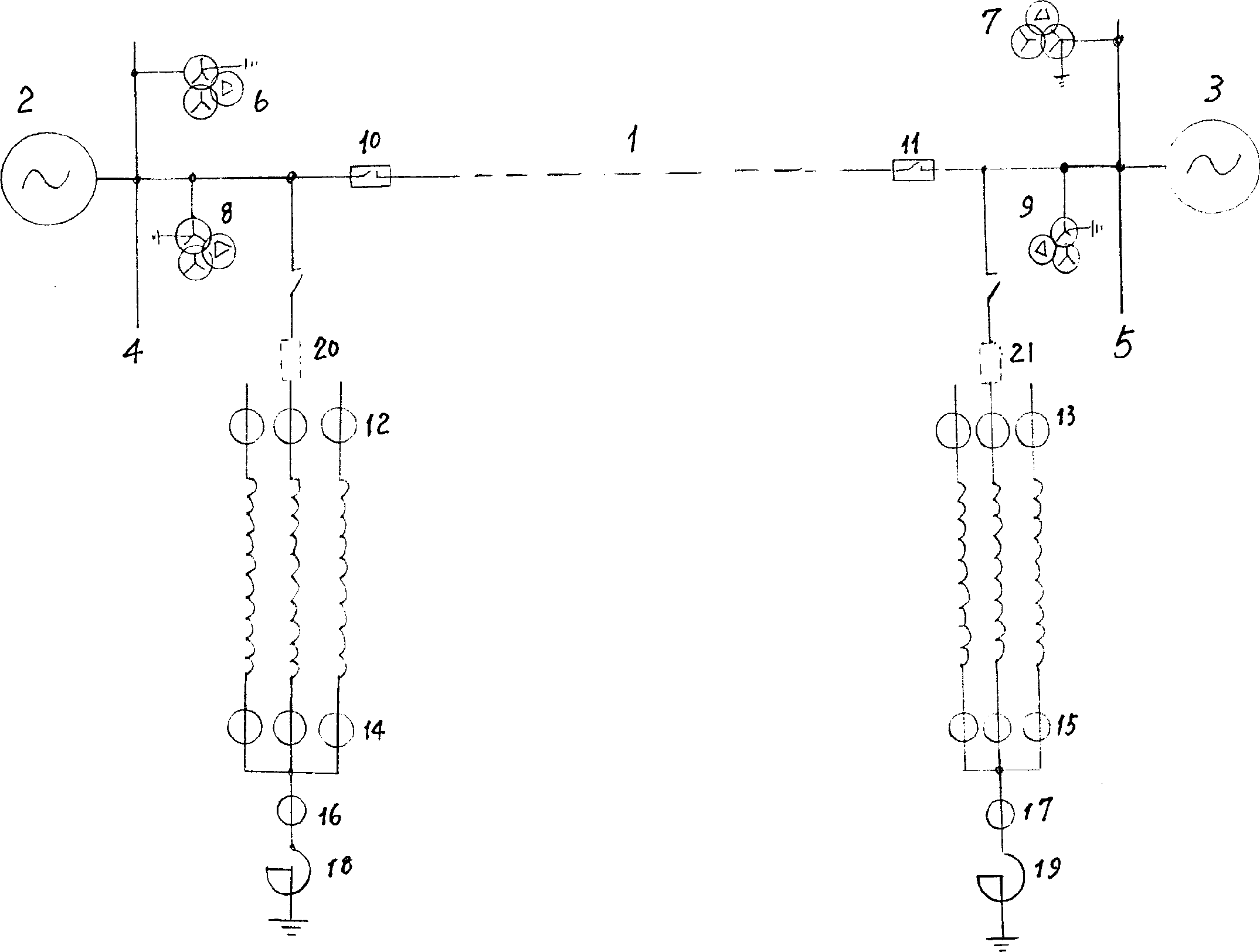

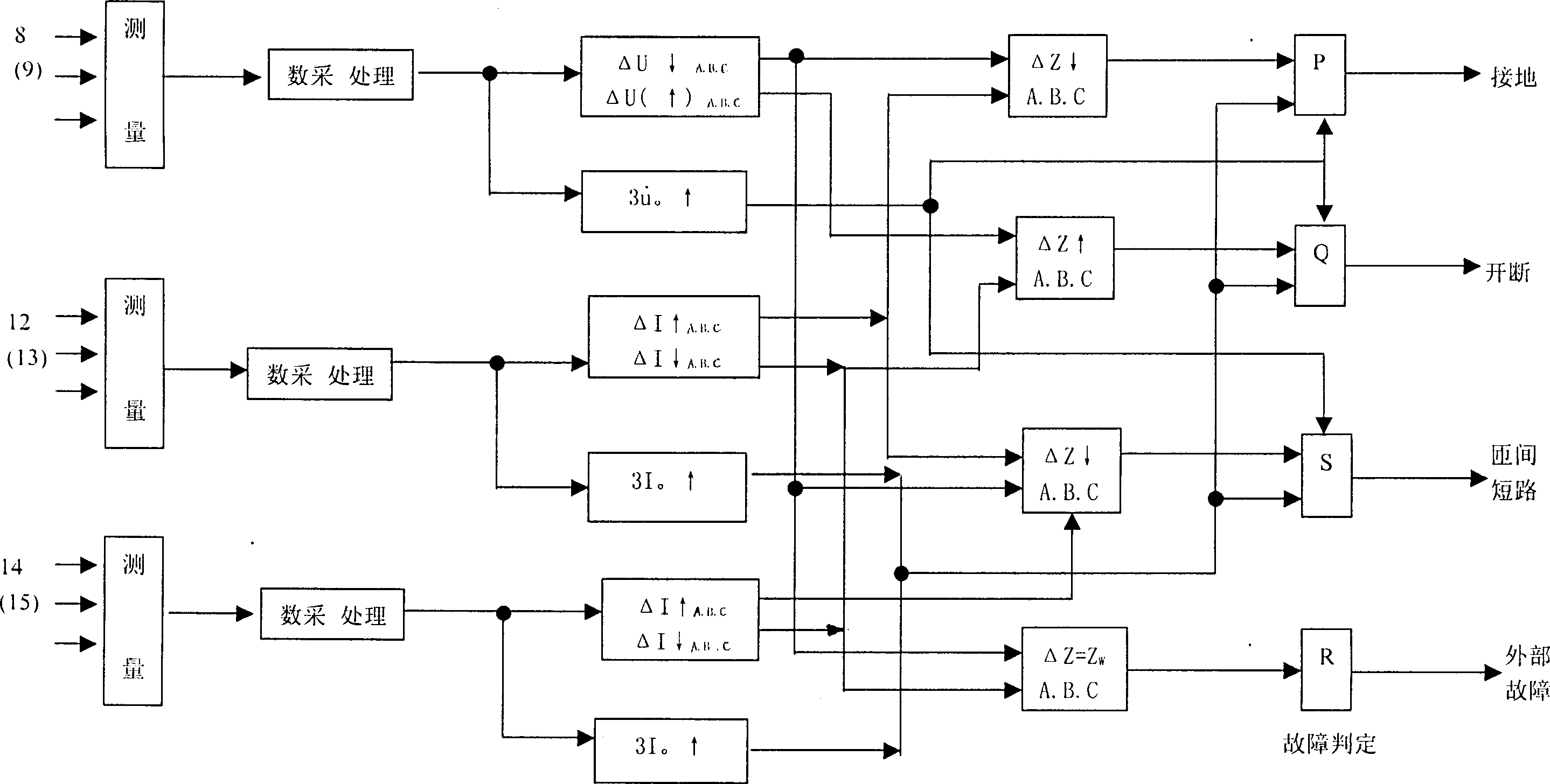

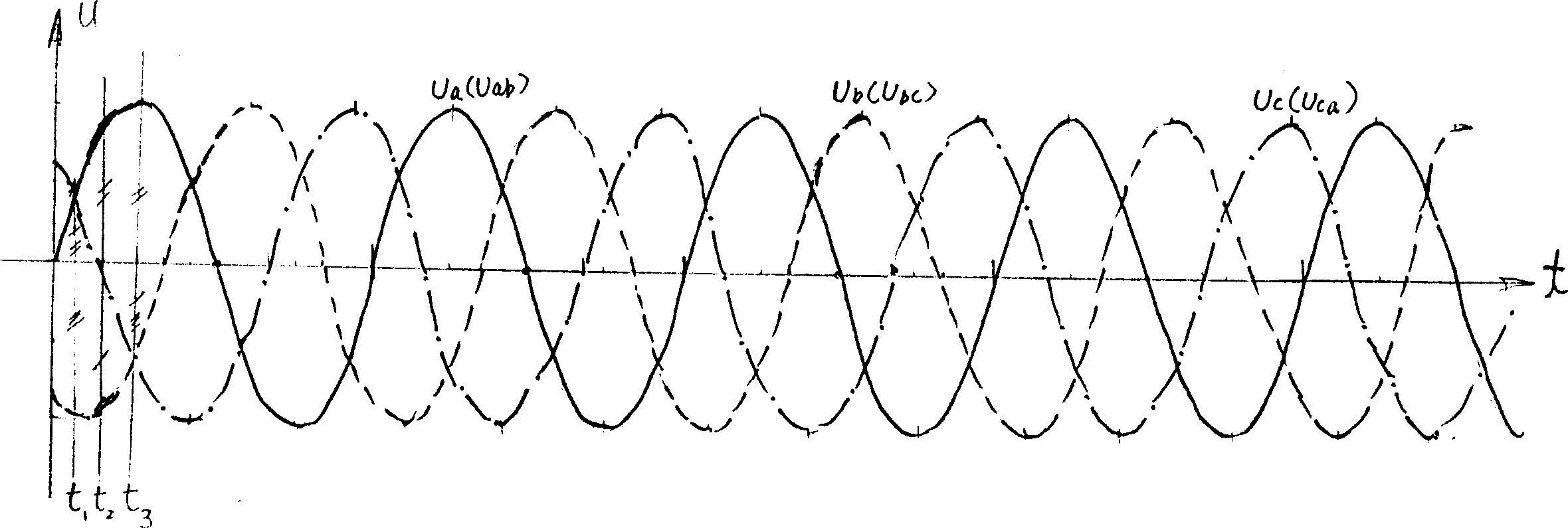

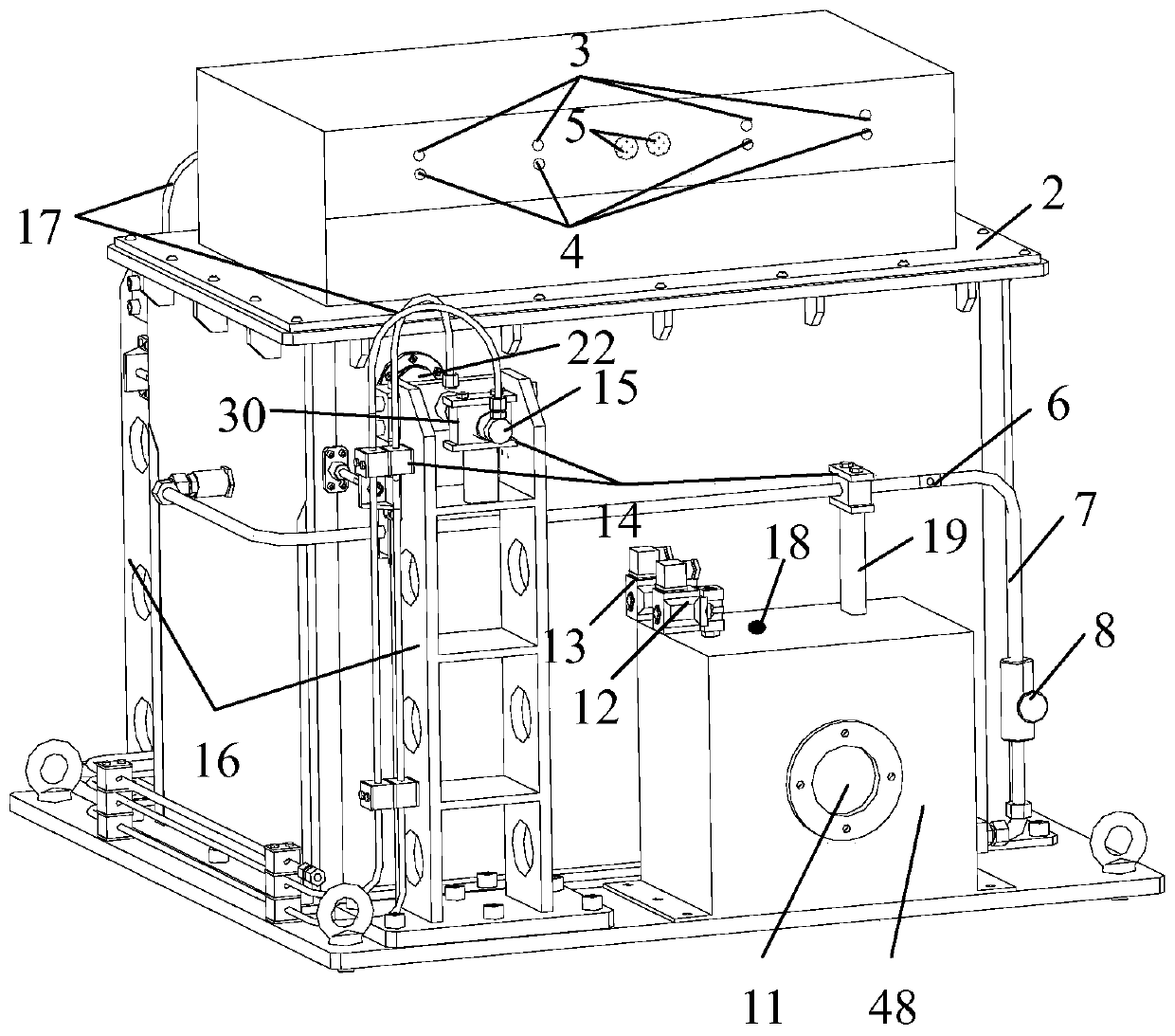

Quick discrimination method for dynamic impedance of parallel reactor

InactiveCN1399381AJudgment time is shortProtection action timeEmergency protective circuit arrangementsShunt reactorTransformer

The present invention relates to parallel reactor relay protection technology for extrahigh and veryhigh voltage electric power system. It includes real-time digital collection, fast judging voltage abrupt reduction in failure phase based on sinusoidal theorem, fast calculation of dynamic impedance abrupt change in failure phase and impedance difference in different phases. The present invention judges the failure property via comparing the abrupt change in dynamic impedance of the failure phase and makes the failure phase to trip after re-judgement. According to the change of voltage, current and impedance of the various phases, different failures, including earthing inside winding, voltage transformer loop failure, turn to turn short circuit and winding open-circuit, may be judged.

Owner:NANJING GUODIAN NANZI POWER GRID AUTOMATION CO LTD

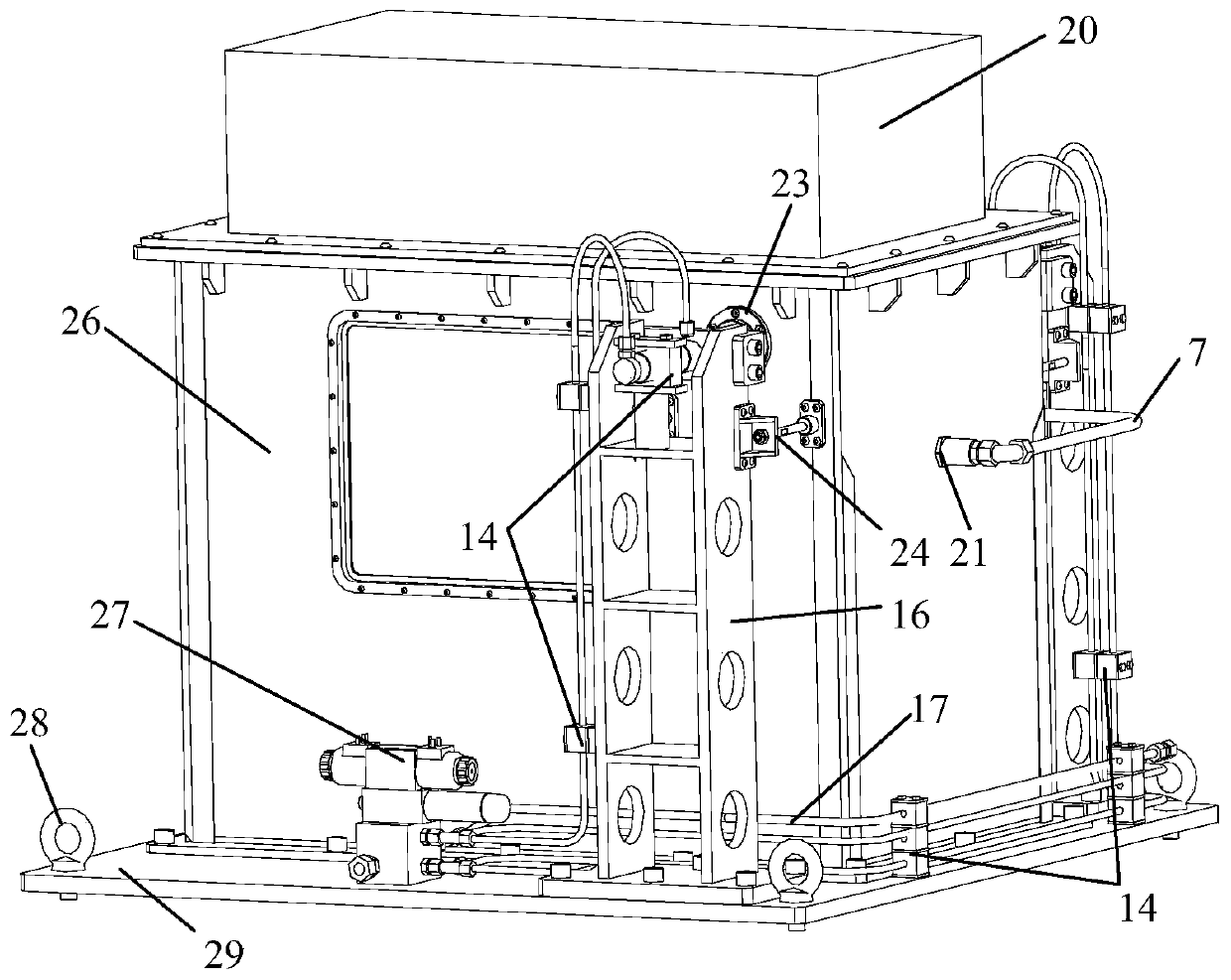

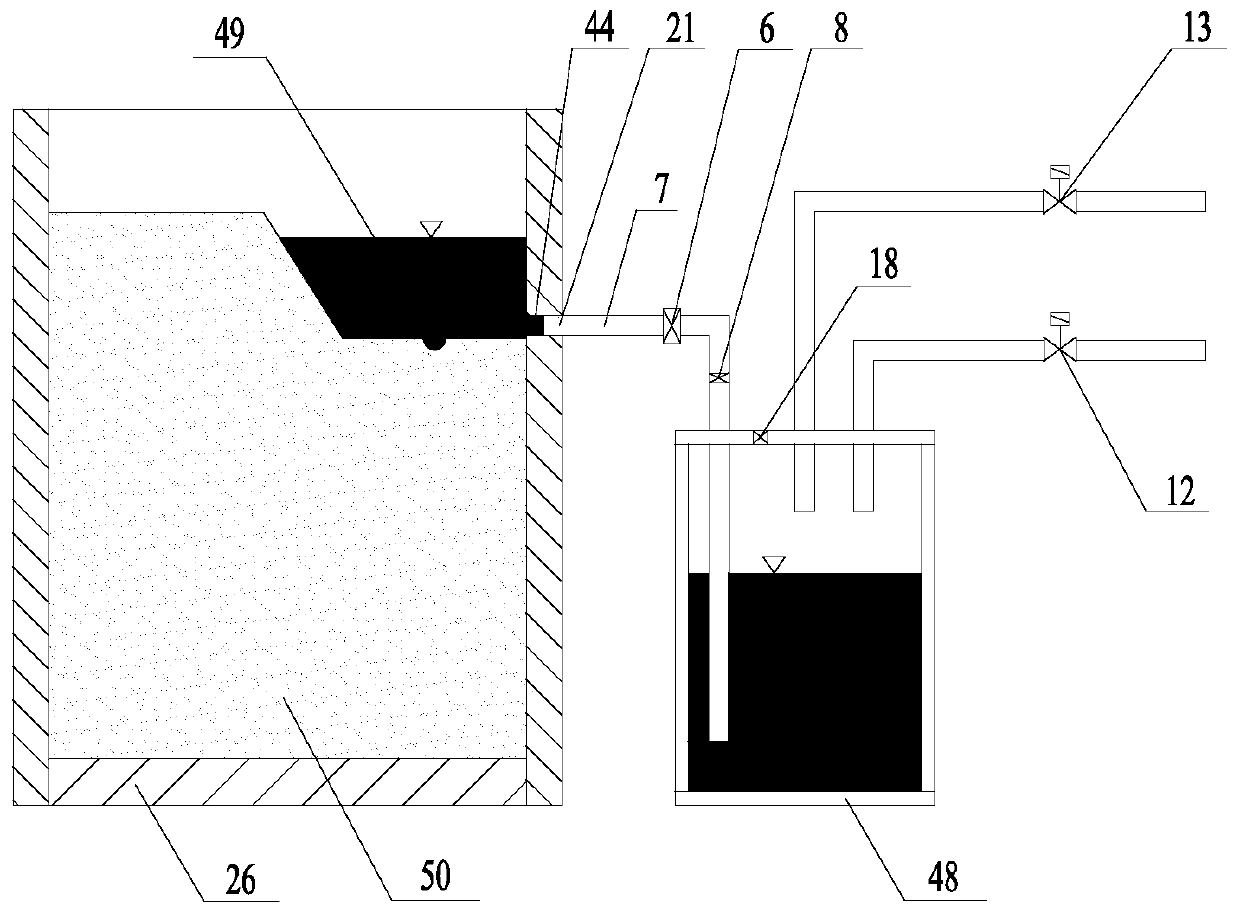

Wet and dry freezing and thawing circulation centrifugation simulation system for cold region water delivery channel, and simulation method thereof

ActiveCN110133218ASolving deformation testing challengesRapid coolingEarth material testingTemperature controlDigital collections

The invention discloses a wet and dry freezing and thawing circulation centrifugation simulation system for a cold region water delivery channel, and a simulation method thereof. The system comprisesa model box, a water level lifting device, an air drying device, a heat exchange device, an air internal circulation device and a digital collection temperature control device. A simulation method based on the above simulation system comprises the following steps that: assembling experiment equipment; simulating the single-time wet and dry freezing and thawing process of the channel and the repeated wet and dry freezing and thawing circulation process of the channel. The water level lifting simulation process and the field channel water introduction and stopping process of the simulation system are consistent; an air drying process is consistent with a field drying process; and a refrigeration board is positioned on the top in the model box, a cold quantity is downwards transferred to thechannel bottom of the model through a fan from the refrigeration board, the simulation of channel model freezing and thawing process is realized through the surface of a model soil mass from top to bottom, which is consistent with a practical soil mass freezing and thawing process. Therefore, a practical situation is highly reduced and simulated.

Owner:NANJING HYDRAULIC RES INST

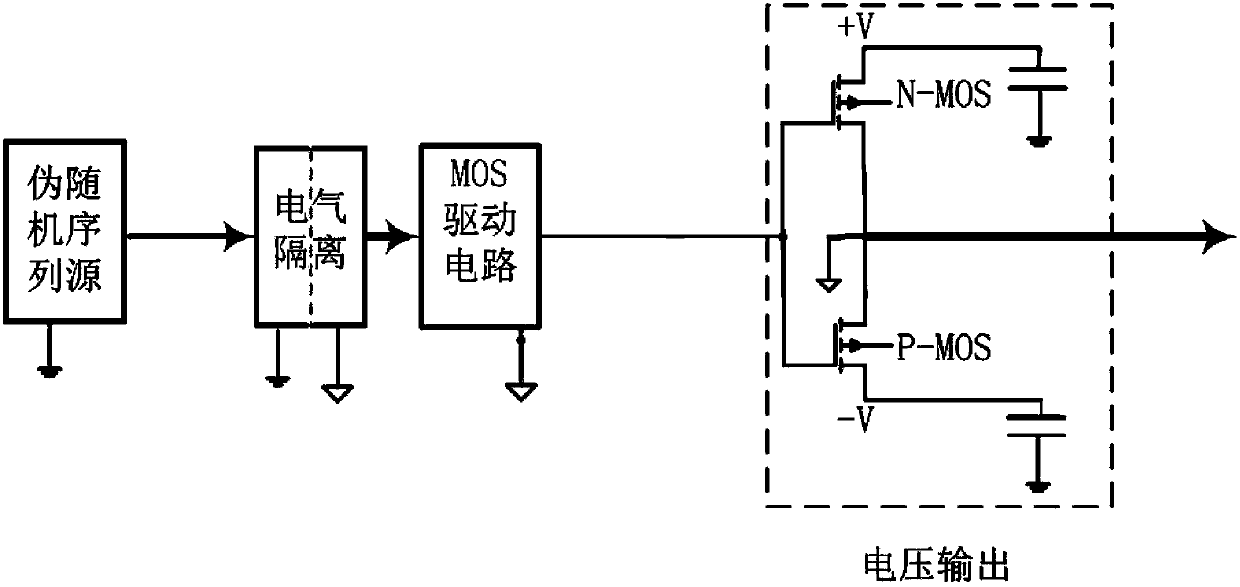

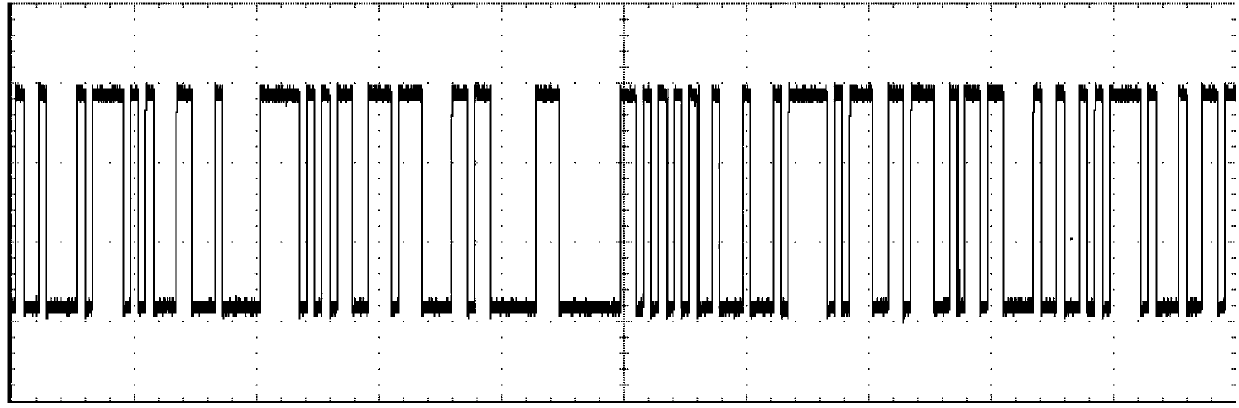

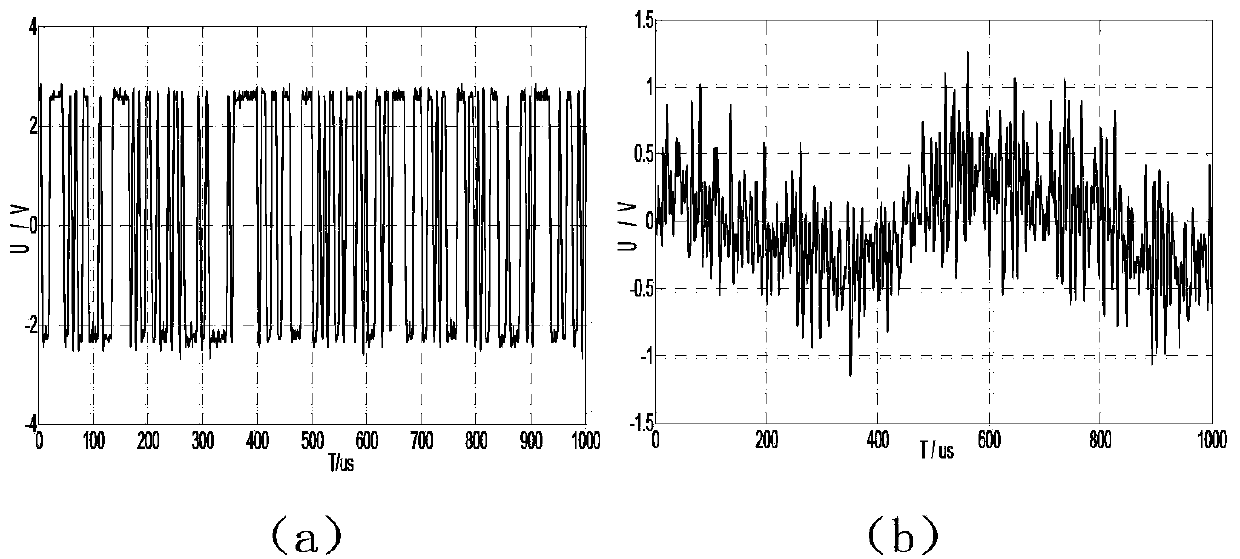

Method for identifying state of power transformer winding by using pseudorandom sequence

ActiveCN103399255AAccurate judgmentComprehensive and reliable reflectionElectrical testingWind systemCorrelation function

The invention provides a method for identifying a state of a power transformer winding by using a pseudorandom sequence. The method comprises the following steps: adopting an M sequence in the pseudorandom sequence as a signal source; after exciting a winding system, collecting input and output signals by using double-channel digital collection equipment; calculating to obtain a pulse response transferring function of the winding system according to the input and output signals; then carrying out correlation function calculation on the input and output signals to obtain a pulse response of the winding system; then describing the state of the winding according to a derivation parameter and a frequency response curve; and judging whether the transformer winding is deformed or not. The testing method disclosed by the invention can be used for comparing amplitude-frequency response curves of the transformer winding and has the consistency. The method disclosed by the invention has the characteristics that the pulse response transferring function of the winding can be directly obtained, the measurement time is short and the like; and furthermore, the method disclosed by the invention can judge the state of the transformer winding according to the change of specific parameters, including poles, null points and the like, of the transferring function, so that the problem in the prior art that technicists easily carry out erroneous judgment is solved.

Owner:XI AN JIAOTONG UNIV

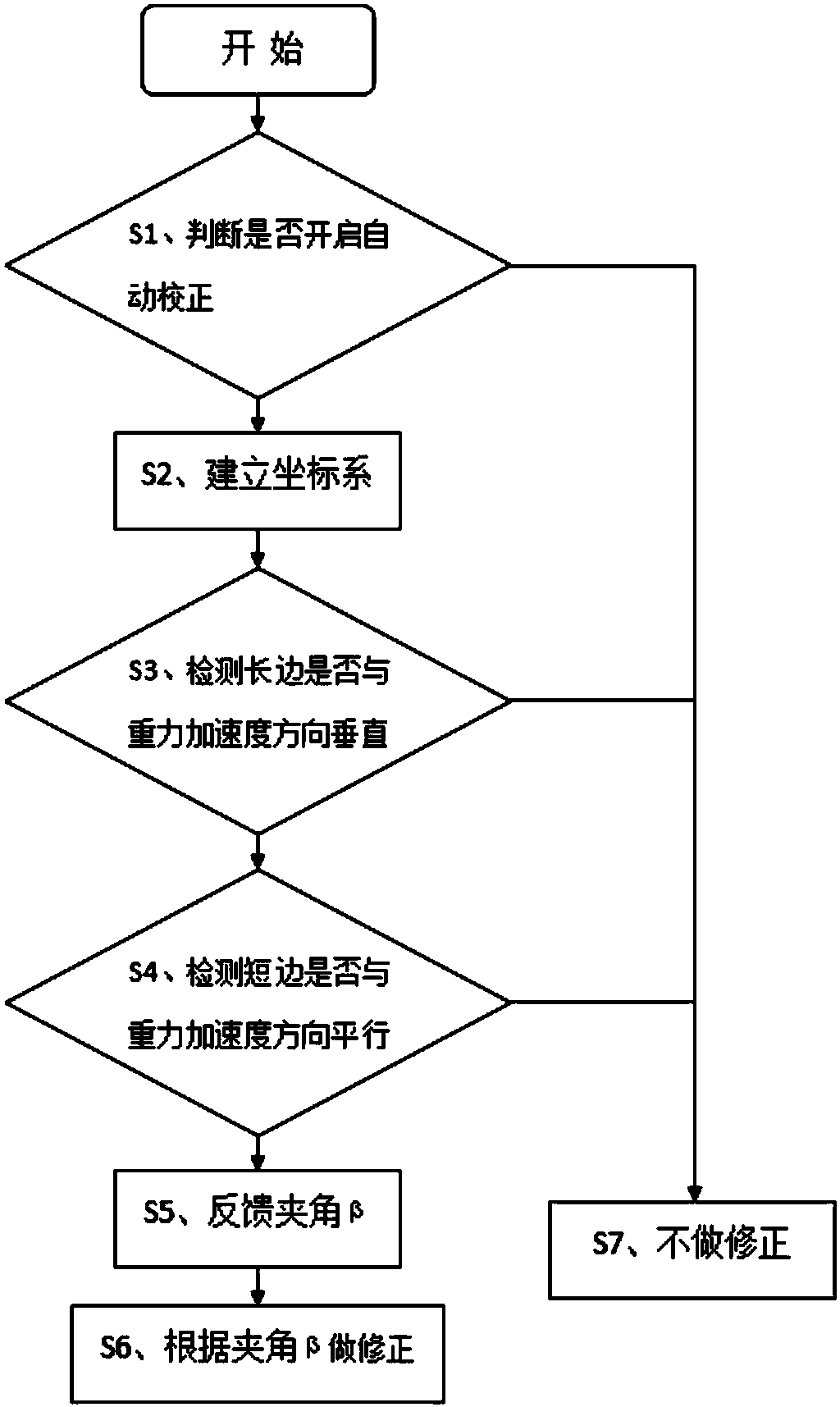

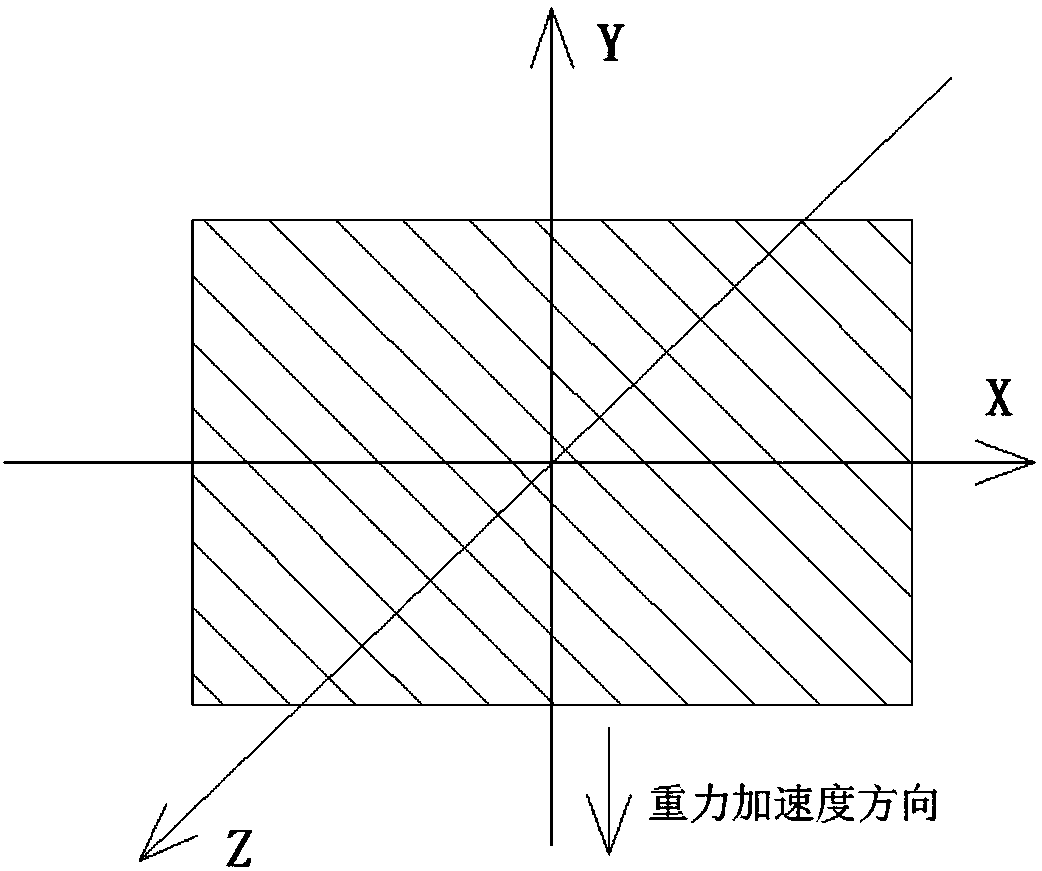

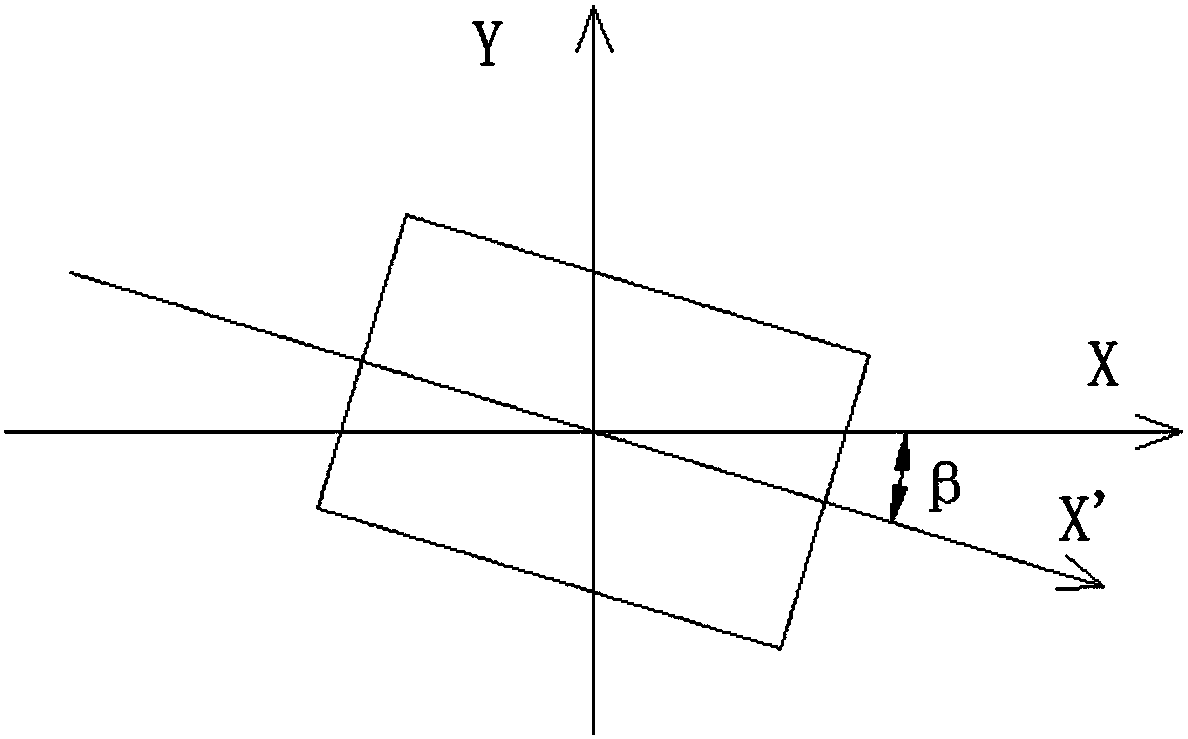

Autocorrection collection device and method of portable image collection terminal

InactiveCN108401115AGuaranteed Horizontal Viewing AngleWarranty requirementsTelevision system detailsColor television detailsAutocorrectionDigital collections

The invention discloses an autocorrection collection device and method of a portable image collection terminal. The device comprises an image collection module and a posture detection module, the posture detection module comprises an angle detection module and a judgment module, the judgment module detects whether the image collection module starts an automatic correction function, and the image collection module collects image information required for a user in real time, and performs rotary correction on the collected image according to the result returned by the judgment module and the angular deflection detected by the angle detection module. According to the method, the rotary correction is performed on the collected image according to the result returned by the judgment module and the angular deflection detected by the angle detection module. The autocorrection collection device disclosed by the invention allows digital collection equipment to automatically correct the shooting angle when collecting images to ensure that even if the digital collection equipment has a certain angle while collecting the images, the collected images and videos are always located in a horizontalview angle or a vertical view angle; and the autocorrection collection device and method have the advantages of simple implementation mode, good user experience and so on.

Owner:北京触链科技有限公司

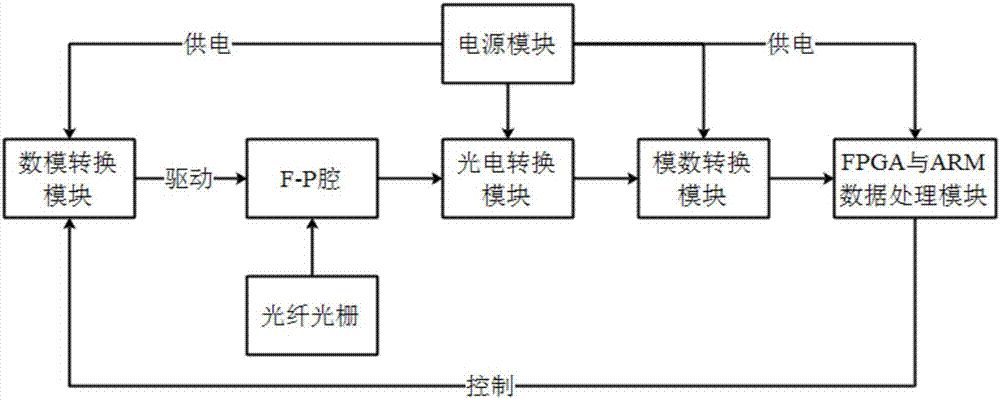

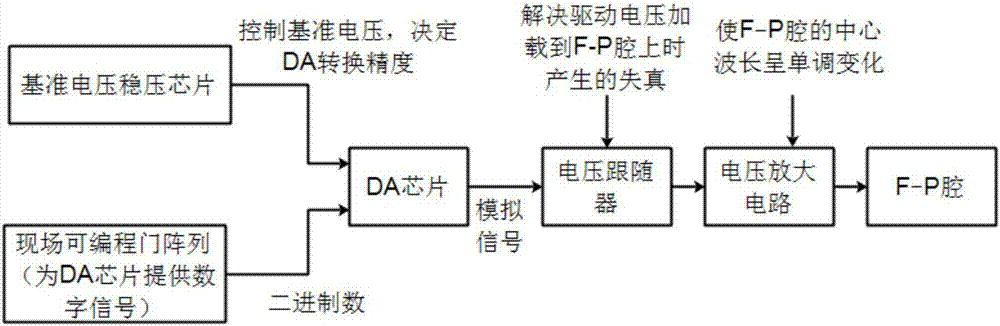

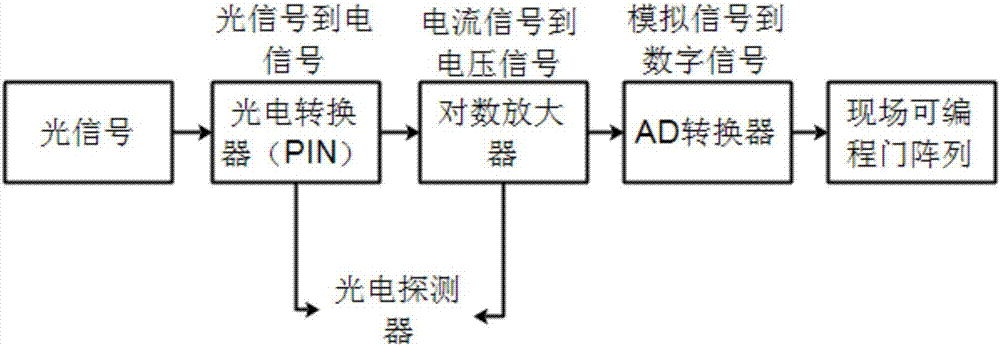

Implementation method for FBG (fiber bragg grating) sensor hardware demodulation system based on FPGA and ARM

InactiveCN107300394ASimplify Design WorkReduce complexityConverting sensor output opticallyGratingDigital collections

The invention provides an implementation method for an FBG (fiber bragg grating) sensor hardware demodulation system based on an FPGA and an ARM. The method comprises the following steps: 1, building a structure health monitoring hardware system for an FBG sensor; 2, designing a power module of the hardware system; 3, designing a digital simulation conversion module; 4, designing a photoelectric conversion module; 5, designing an analog-digital collection module; 6, designing a data processing module. The method combines the FPGA and the ARM to complete the data preprocessing, the generation of an F-P cavity drive signal and the wavelength algorithm implementation. Through the above steps, the method achieves the FBG sensor hardware demodulation system based on the FPGA and the ARM, and can achieve the demodulation of a wavelength signal of an FBG. In addition, the hardware system enables all function modules to be packaged into modules, thereby simplifying the design of the system. The modules can be debugged and operate independently, thereby facilitating the reduction of complexity of the system, and enabling the system upgrading, debugging and maintenance to be simplified.

Owner:BEIHANG UNIV

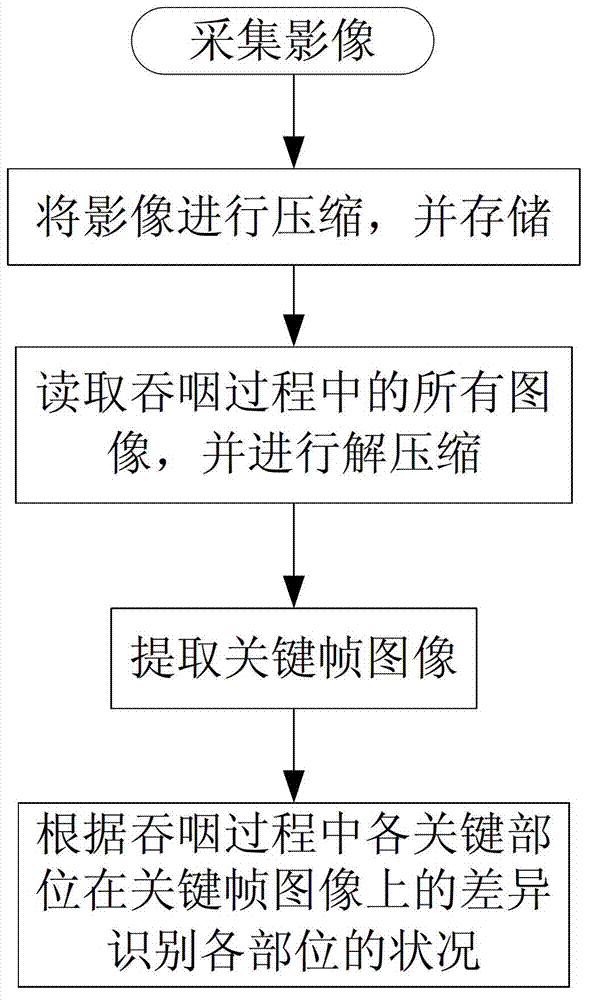

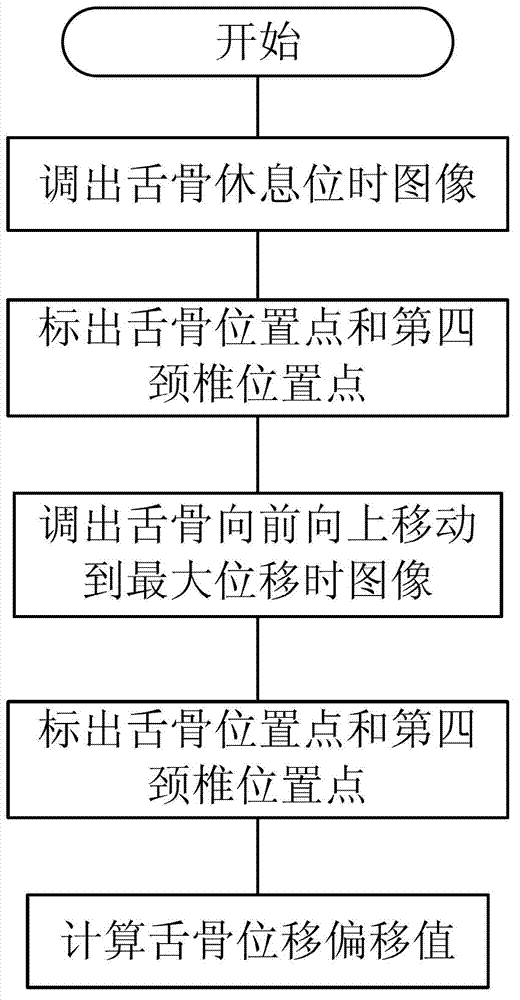

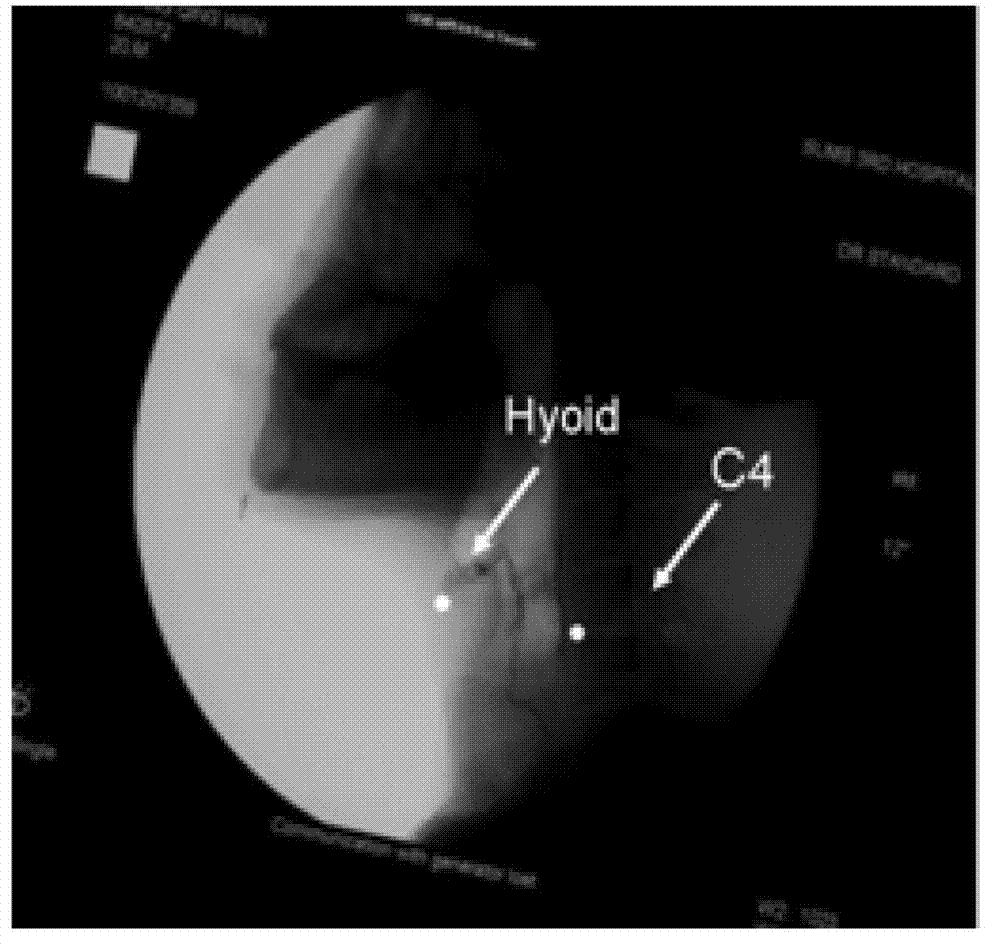

Medical swallowing image collection device and image processing method thereof

InactiveCN103202703AAccurate image dataAccurate Diagnosis ReferenceImage analysisRadiation diagnosticsGastrointestinal deviceImaging processing

The invention discloses a medical swallowing image collection device and an image processing method thereof. The device comprises a digital collection card, a computer and a display. The digital collection card is inserted into a slot of a peripheral component interconnect-express (PCI-E) of the computer, is connected with a digital gastrointestinal device through a data line and sends collected image data of the digital gastrointestinal device to the computer in real time. The computer further comprises a memory for storing the image data and a processing module for processing images. The method comprises the steps of reading images in the swallowing process; extracting key frame images in the swallowing process; and identifying conditions of every part according to difference of every key part on the key frame images in the swallowing process. The medical swallowing image collection device is high in collecting precision; by image data processing, detailed quantitative analysis can be performed on the dynamic swallowing process, and every key parameter is measured and calculated; and image data can be called at any time so as to be used for reassessment and therapeutic effect comparison.

Owner:GUANGZHOU LONGEST SCI & TECH +1

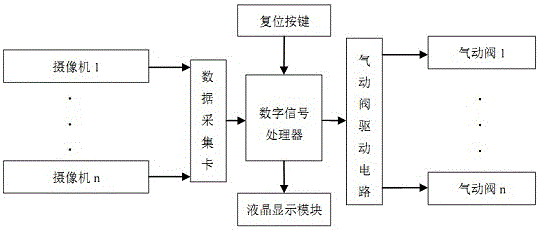

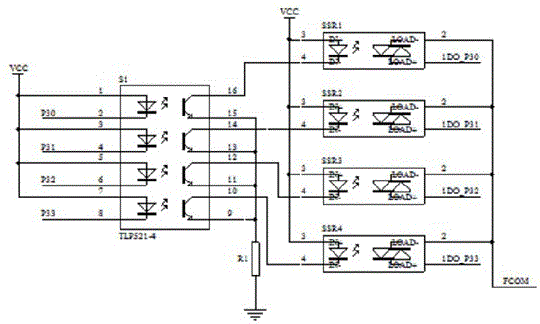

Rejecting control device for tobacco impurities

The invention discloses a rejecting control device for tobacco impurities. The device comprises a camera set, a digital collection card, a digital signal processor, a pneumatic valve set A, a pneumatic valve set B, a pneumatic valve driving circuit and a tobacco leaf conveying belt. The camera set is used for collecting image information, the digital collection card is used for processing the image information collected by the camera set, the digital signal processor is used for receiving the information which is processed by the digital collection card, the pneumatic valve set A is used for jetting out high-speed airflow to vertically reject the impurities in tobaccos, the pneumatic valve set B is used for blowing the impurities into an impurity containing groove, and the pneumatic valve driving circuit and the tobacco leaf conveying belt are connected with the digital signal processor and drive the pneumatic valve set A and the pneumatic valve set B to work. Pneumatic valves are tightly arrayed to form a seamless connection array, in this way, the corrective rate during rejecting is increased, and the working efficiency of tobacco leaf sorting equipment is improved; the pneumatic valves jet out the high-speed airflow to reject the impurities in the tobaccos, and during detecting, speed is high, reliability is high, and normal tobacco leafs are not damaged.

Owner:HEFEI NORMAL UNIV

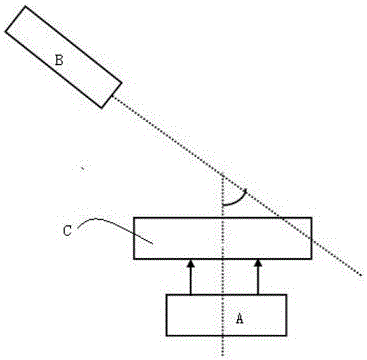

Rock three-dimensional stress monitoring system and measuring device

The invention relates to a rock three-dimensional stress monitoring system and measuring device. The rock three-dimensional stress monitoring system and measuring device comprises a local digital collecting system and a hollow inclusion stress detector. The hollow inclusion stress detector is fixed inside the drill hole of an object to be measured; the local digital collecting system obtains the strain response of the hollow inclusion stress detector during the stress relieving process of a drilling core. The rock three-dimensional stress monitoring system and measuring device has the advantages of achieving synchronization of digital collection and digital measurement, and by combining a collector with the hollow inclusion stress detector, saving operation through a microcomputer terminal, thereby reducing the thermal effect influence on the stress detector, achieving spatial three-dimensional stress computation and saving time and labor.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com