Method and system for detecting parameters of tinning furnace

A parameter detection and tin furnace technology, applied in the detection field, can solve the problems of glass breakage, rework, and high cost, and achieve the effects of easy analysis and processing, improved detection accuracy, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

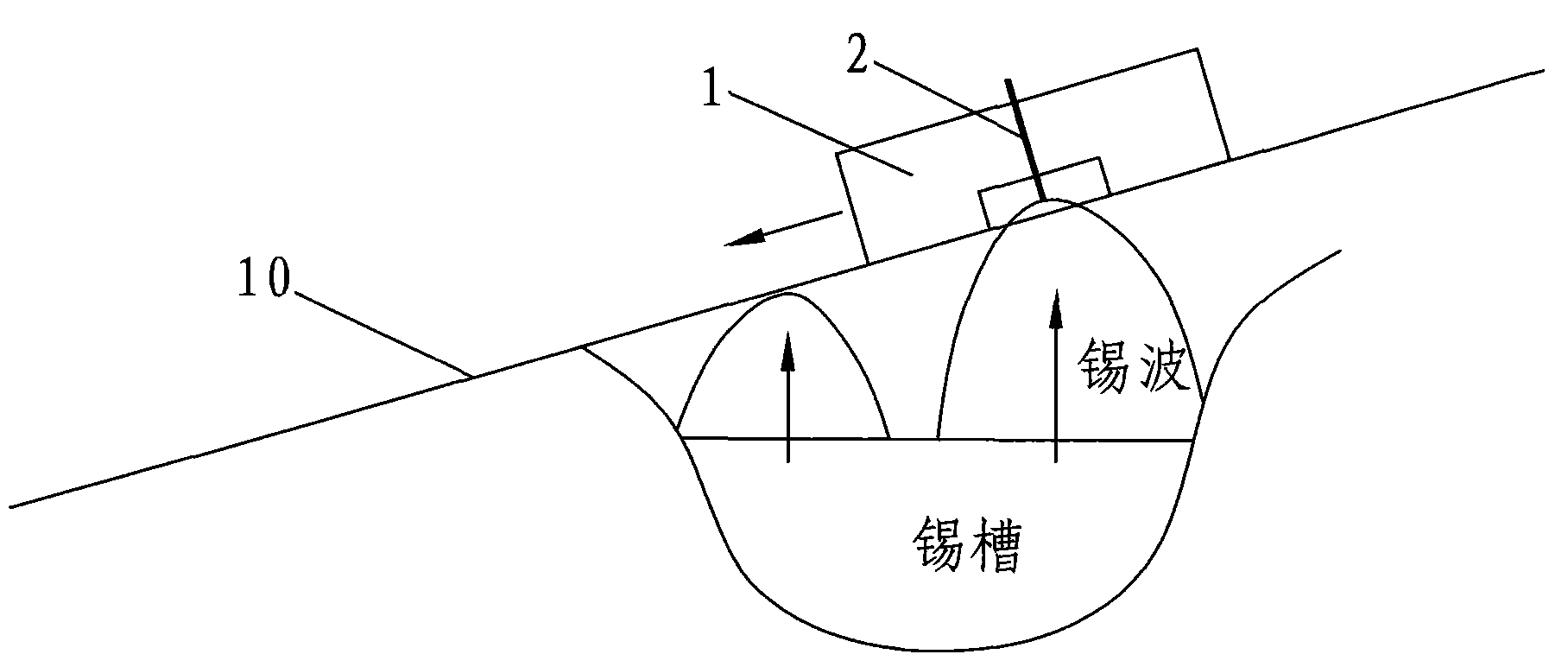

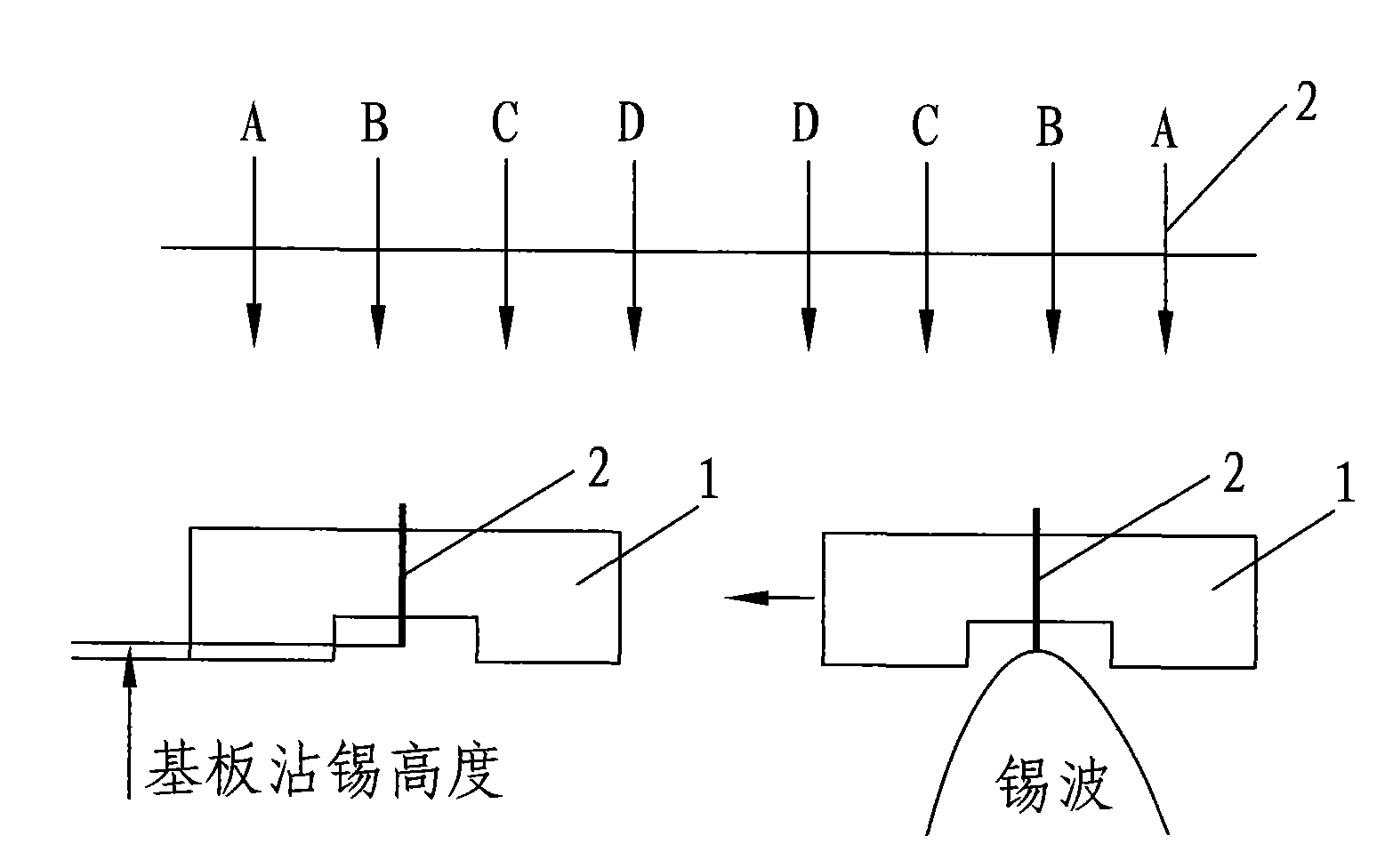

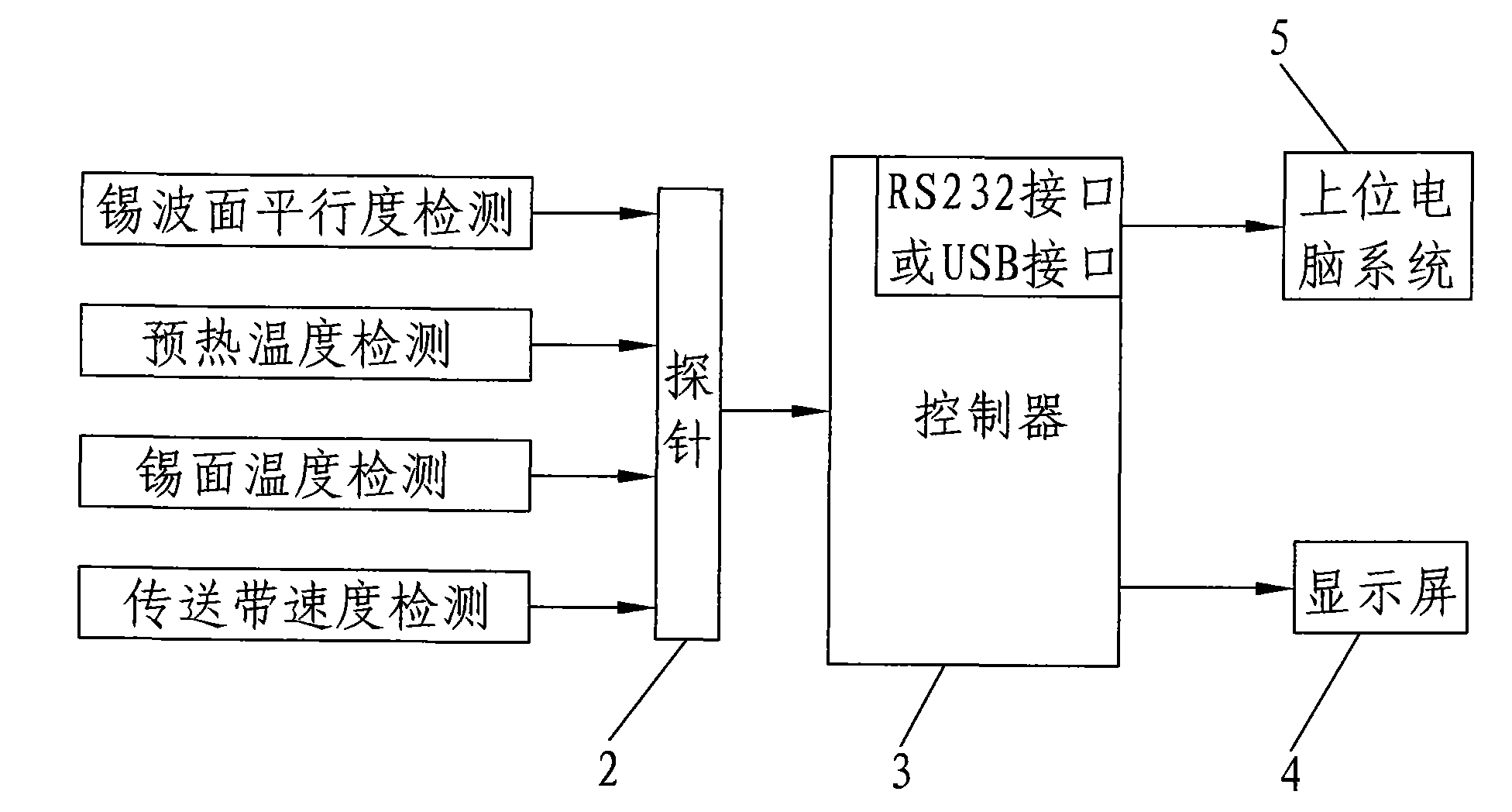

[0030] Below in conjunction with accompanying drawing, the present invention will be further described, see Figure 1~2 Shown, tin furnace parameter detection method, it comprises the following steps:

[0031] A. A plurality of probes 2 are arranged in a straight line perpendicular to the transmission track 10, divided into symmetrical left and right parts, distributed on both sides of the transmission track 10 of the tin furnace, and move with the transmission track 10. In this implementation In the example, there are 8 probes 2, 4 on the left and right sides;

[0032] B. Use the probe 2 to detect the temperature of each detection point in the preheating stage, and use the controller 3 to record and store the detection results;

[0033] C. Digitally sample the detection temperature of each probe 2 every other sampling period, the sampling period is 0.1s, the controller 3 compares the sampling data with the detection temperature of the probe 2 in the preheating stage, and jud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com