Cutter ring and cutter body matching surface positive pressure test system and test method of hobbing cutter

A technology for testing systems and mating surfaces, applied to force/torque/power measuring instruments, measuring devices, instruments, etc., to achieve the effect of improving service life and accurate and reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Specific implementation one.

[0067] Combine now Figure 1 to Figure 18 The first specific implementation of the present invention will be described in detail.

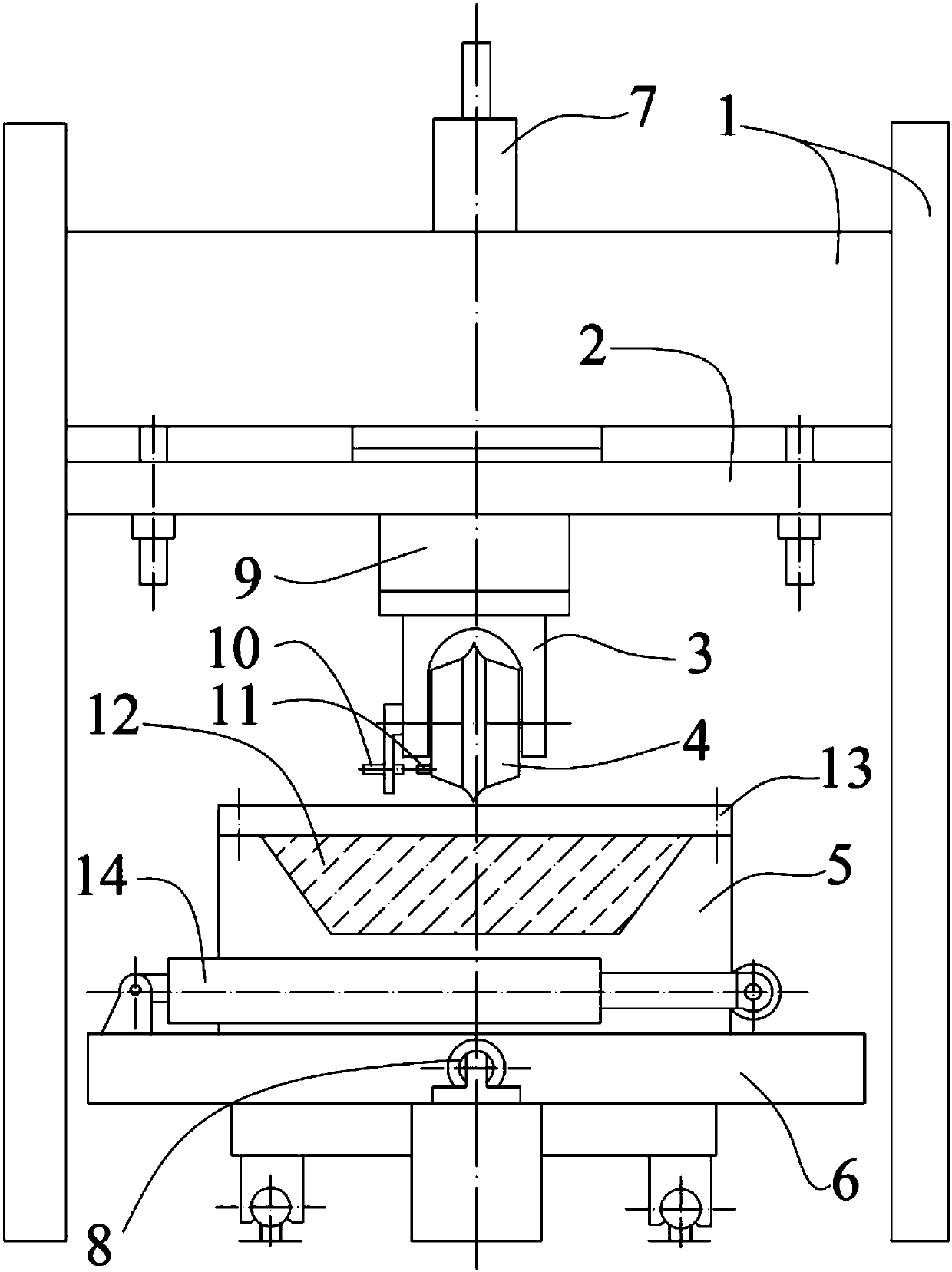

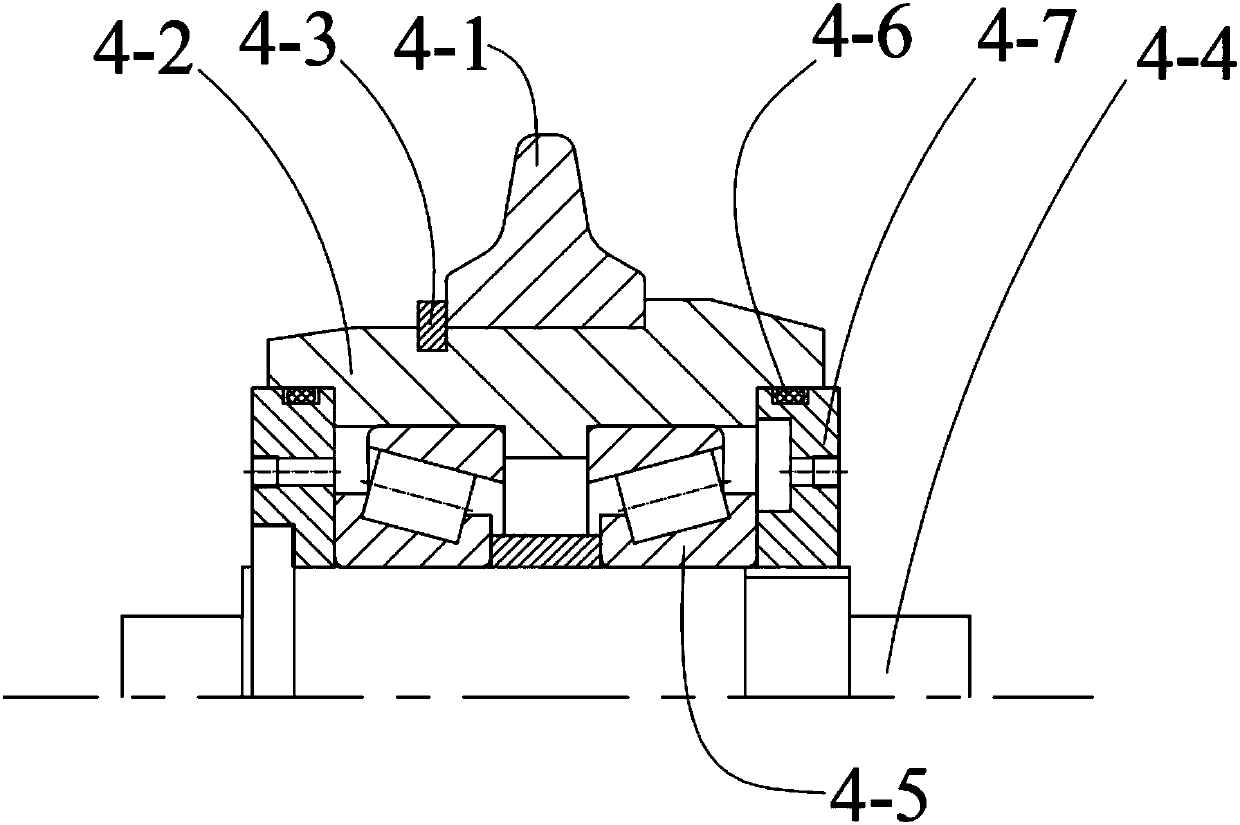

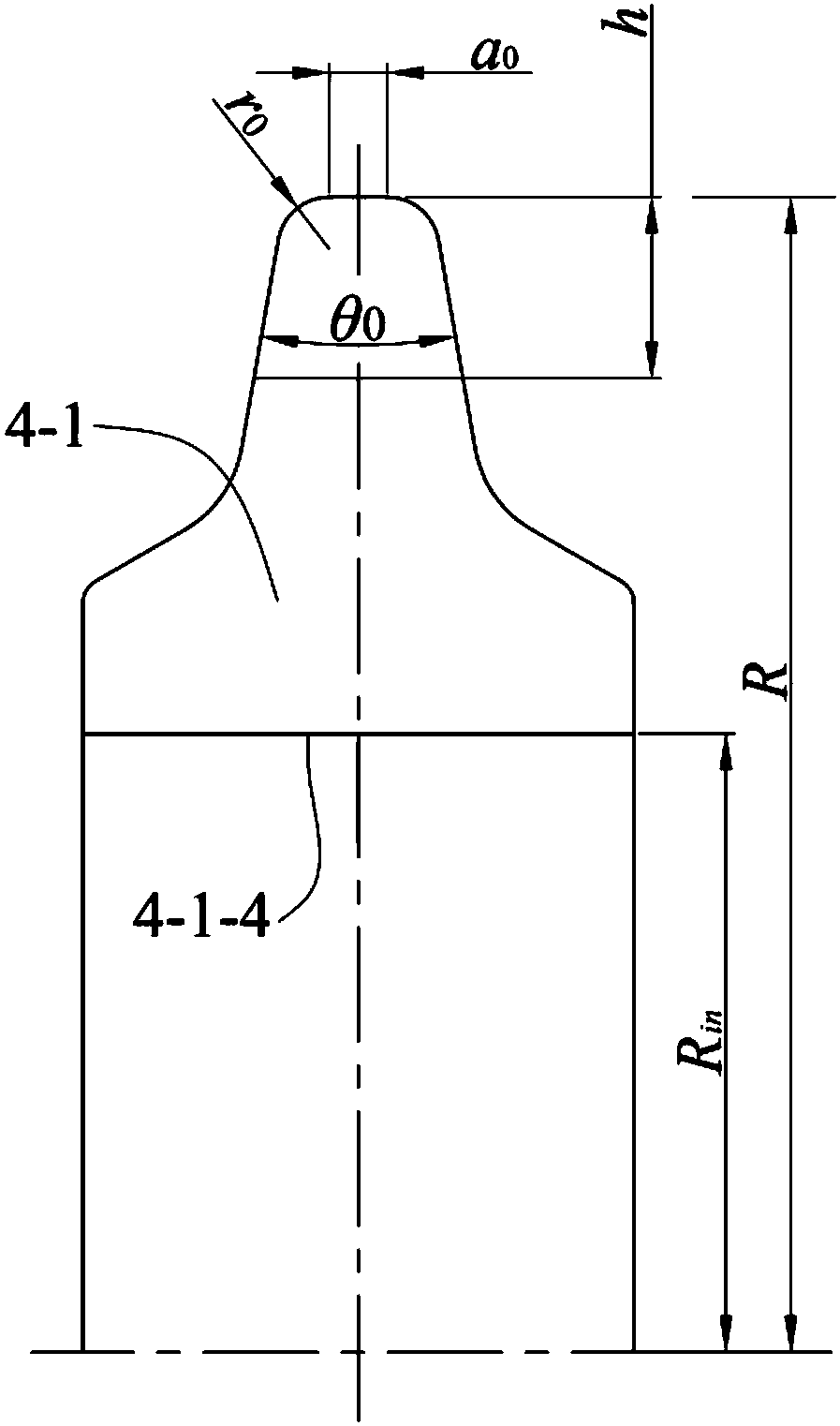

[0068] The present invention is a positive pressure test system for the mating surface of the cutter body of the hob cutter ring, which includes such as figure 1 The hob standard wire cutting test bench shown, data acquisition instrument (not shown), hob (4), eddy current displacement sensor (only its probe (10) is shown), industrial computer (not shown), pressure sensor (only at Figure 4 to Figure 15 Draw the pressure sensing area of the pressure sensor (4-8)); figure 1 As shown, the hob standard wire cutting test bench usually includes a frame (1), a movable beam (2), a knife seat (3), a rock material bin (5), a horizontal workbench (6), and a vertical oil cylinder (7) , longitudinal oil cylinder (8) and horizontal oil cylinder (14); image 3 The shown 17-inch constant cross-section flat edge cutter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com