Method for separating thermal noise, shot noise and intensity noise of optical fiber gyroscope

A fiber optic gyroscope and shot noise technology, which is applied in the separation of shot noise and intensity noise, and in the field of fiber optic gyroscope thermal noise, can solve problems such as poor reliability of results and limited accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

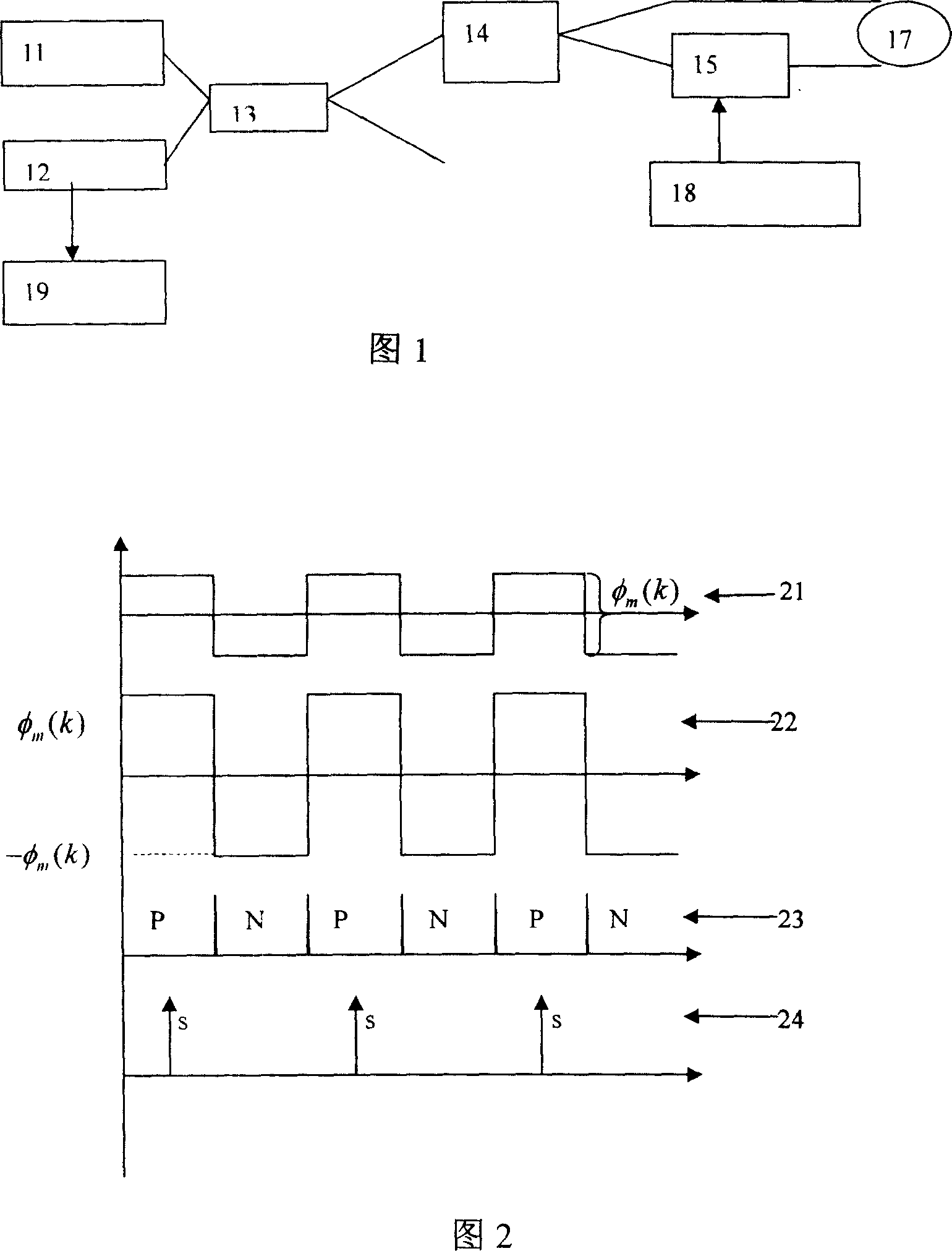

[0044] Figure 1 is a schematic block diagram of a typical test system, in which the light emitted by the light source 11 is divided into two beams by the first beam splitter 13 of the system, one of which reaches the second beam splitter 14 through an optical fiber, and is divided into two , and injected into the two ends of the optical fiber 17, respectively propagating along the clockwise and counterclockwise directions of the optical fiber ring 17, and being modulated by the time delay of the modulator 16 so that there is additionally a modulation depth determined by the modulation waveform, the modulated Waveforms are generated by 18 . The light modulated by the time delay recombines and interferes with each other after propagating separately, and the interference light is reversely split from the beam splitter 14, and part of it reaches the first beam sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com