Implementation method for FBG (fiber bragg grating) sensor hardware demodulation system based on FPGA and ARM

A fiber grating and demodulation system technology, which is applied in the direction of using optical devices to transmit sensing components, etc., can solve the problems of parallel processing capability, poor real-time performance, complex communication of off-chip expansion memory peripherals, inconvenient system upgrades, etc. Problems such as debugging and maintenance, to achieve the effect of powerful parallel signal processing capability, flexible and fast switching, and simplified design work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

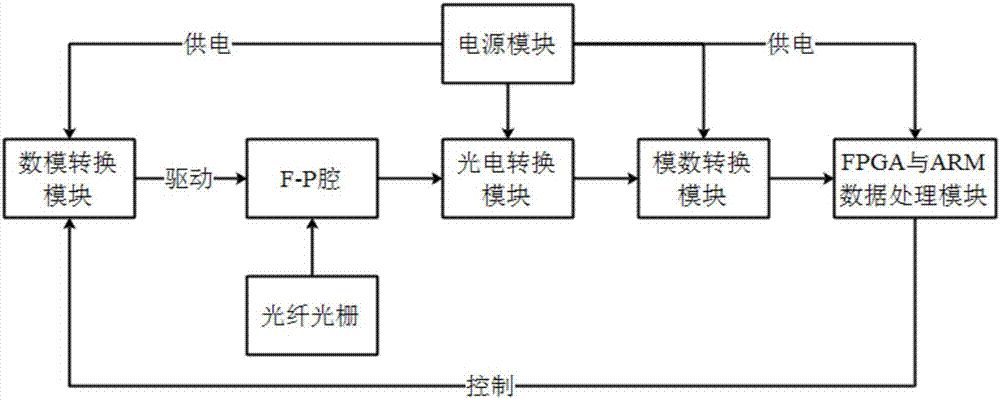

[0034] A kind of implementation method of the fiber grating sensor hardware demodulation system based on FPGA and ARM of the present invention, see figure 1 As shown, the specific steps are as follows:

[0035] Step 1, determine the development board, programming language and processor used by the hardware system. The present invention uses an integrated development board Miz702 (Nanjing Millian Electronics) whose model is XC7Z020-1CLG484I. The integrated development board adopts a platform combining FPGA and ARM processor, and adopts the development software whose version is "Vivado 2015.4" for development;

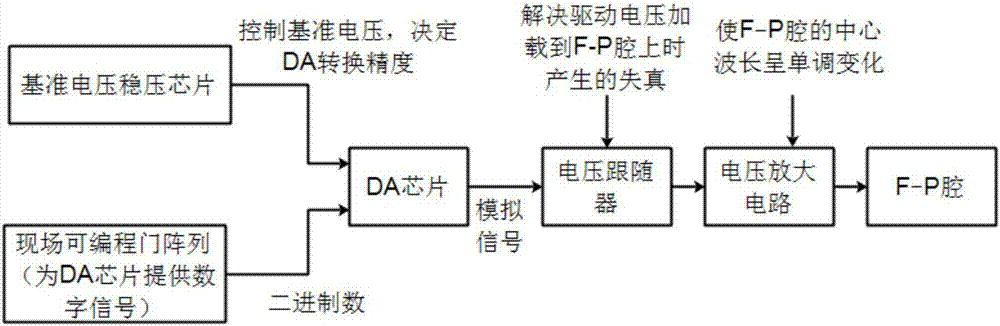

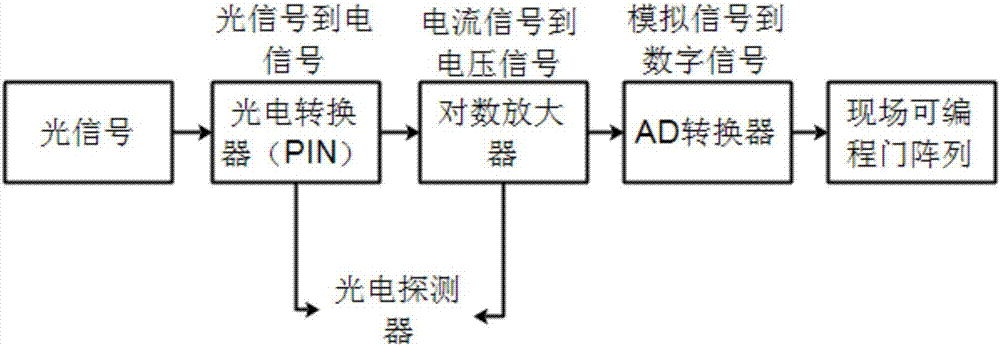

[0036] Step two, the design of the power module. Modules such as analog-to-digital conversion (that is, Analog to Digital, hereinafter referred to as AD) chip, digital-to-analog conversion (that is, Digital to Analog, hereinafter referred to as DA) chip, and photoelectric detection circuit used in the present invention need to provide input voltage. The power module in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com