Cam-driven three-degree-of-freedom parallel manipulator

A degree of freedom and manipulator technology, applied in the field of machinery, can solve the problems of high quality requirements of users, complex motor control, increased cost, etc., to achieve the effect of simplifying design work, high degree of automation, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail:

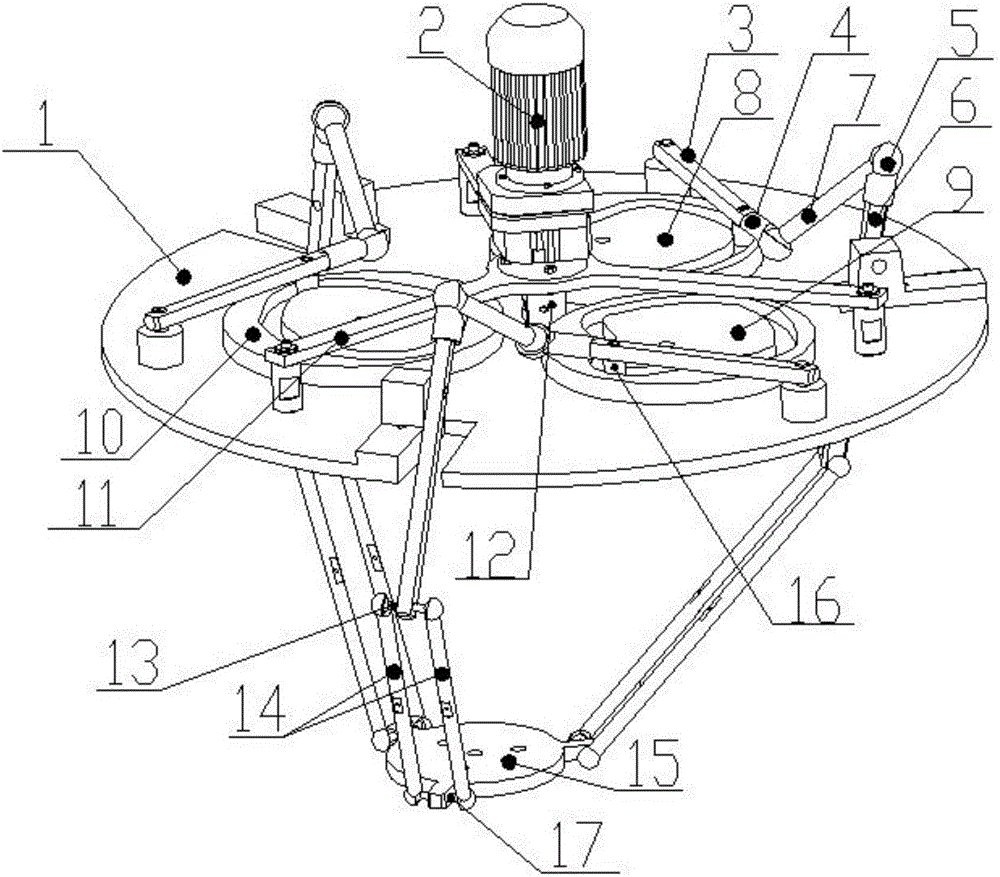

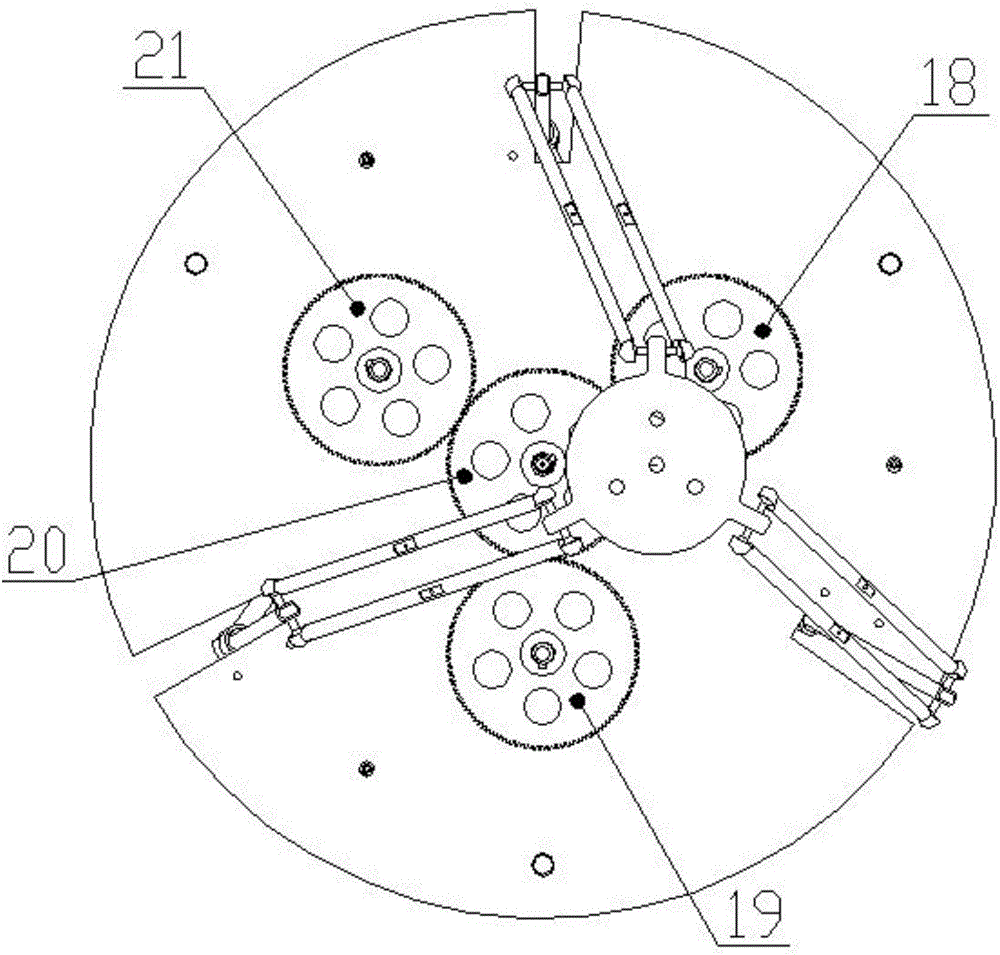

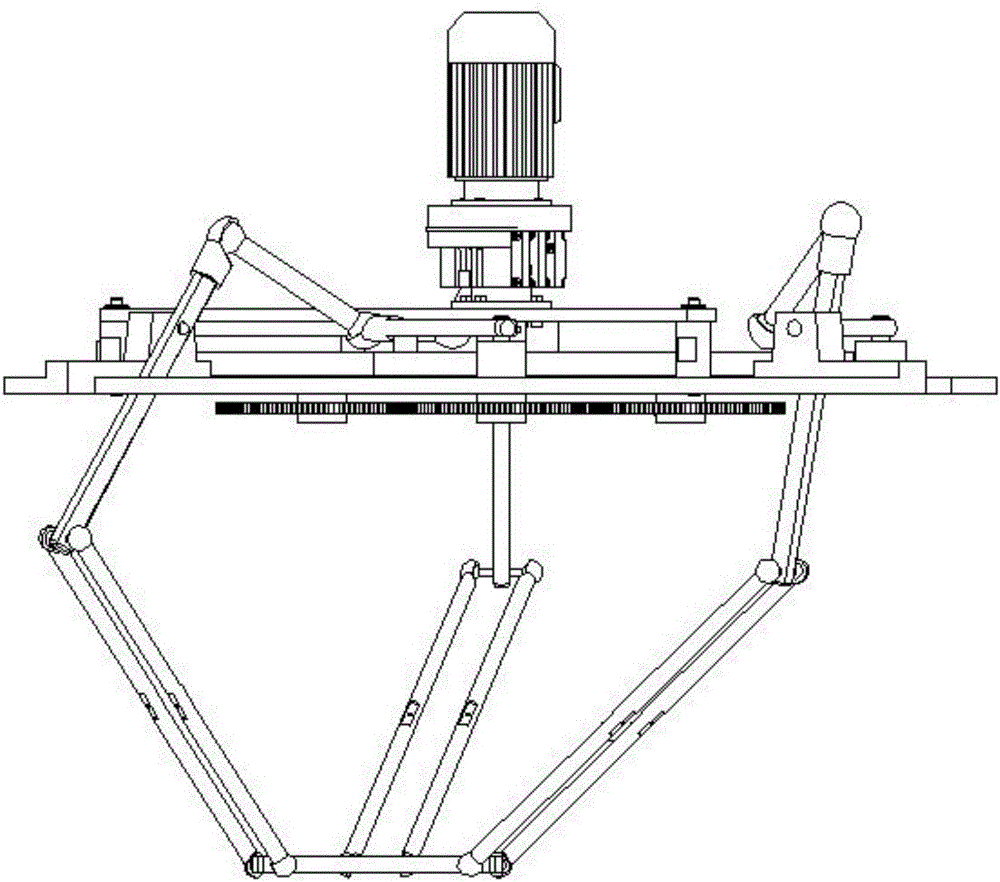

[0029] See attached Figure 1-4 As shown, the cam-driven three-degree-of-freedom parallel manipulator of the present invention includes a fixed platform 1, a motor 2, a swing rod 3, a small ball joint 4, a large ball joint 5, a large arm 6, a connecting rod 7, a first cam 8. Second cam 9, third cam 10, motor mount 11, coupling 12, first pin 13, small arm 14, moving platform 15, roller 16, second pin 17, first gear 18 , the second gear 19, the third gear 20, the fourth gear 21.

[0030] The fixed platform 1 is the base body of the equipment, and can be installed on the work site according to actual needs, and other components are installed with reference to it; the first cam 8, the second cam 9, and the third cam 10 are determined according to the corresponding Position installation, and the three cams are located in the same plane, and the circumferential angle is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com