Multi-component organic-gas pressure-changing adsorption and realtime detection-control experiment device

A pressure swing adsorption, organic gas technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as difficult air purification, and achieve the effects of safe and reliable performance, compact structure, and simple and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

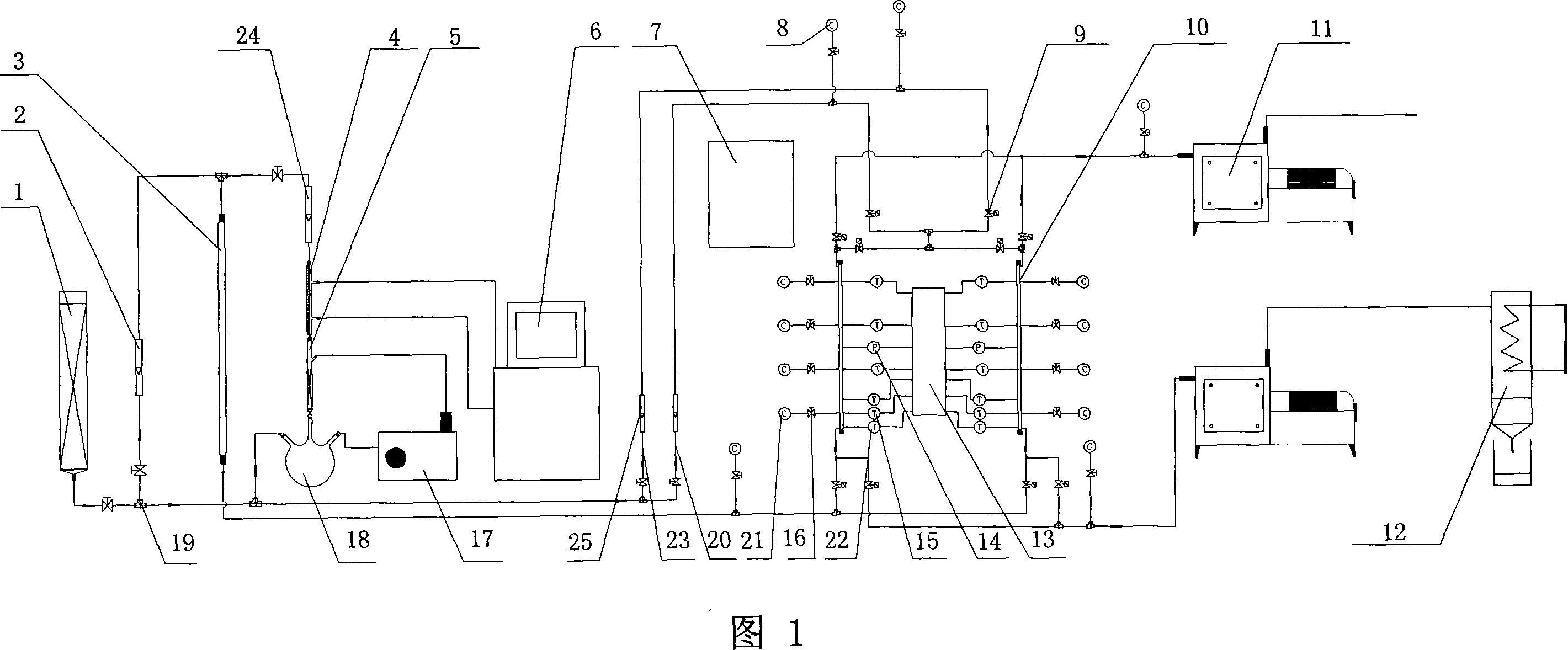

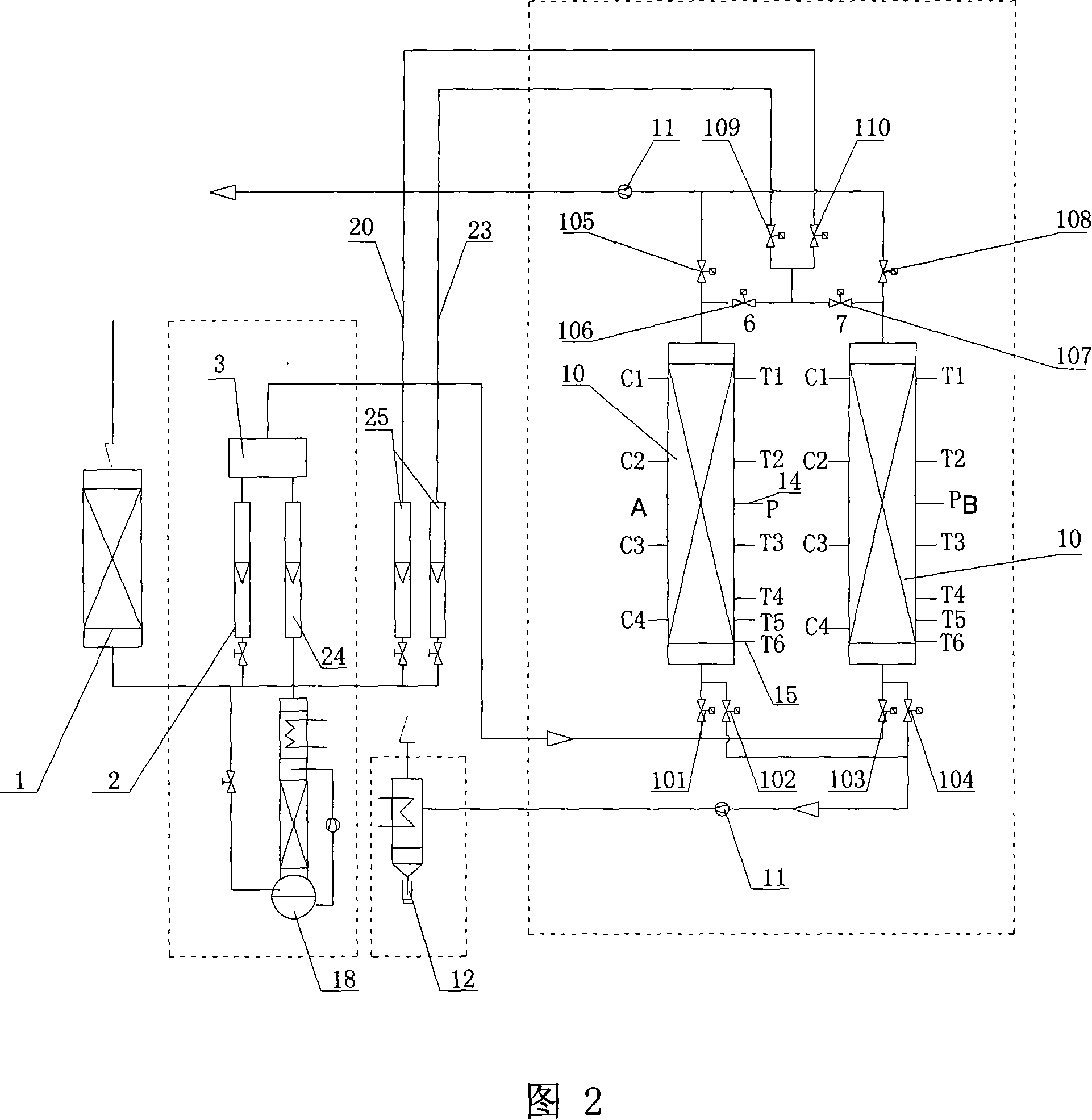

[0013] As shown in Figure 1, a kind of multi-component organic gas pressure swing adsorption and real-time test control experimental device of the present invention, it comprises drying column 1, gas mixing column 3, organic gas generator 18, micro packing column 5 and one or one In the above pressure swing adsorption column 10, the outlet of the drying column 1 is divided into three paths, one path is directly connected to the inlet on the upper end of the pressure swing adsorption column 10, the other path is connected to the air inlet of the gas mixing column 3, and the other path passes through the organic gas The generator 18 and the micro packing column 5 are connected to the air inlet of the gas mixing column 3, and the outlet of the gas mixing column 3 is connected to the air inlet at the lower end of the pressure swing adsorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com