Micro-torsion testing platform

A torsion test and platform technology, which is applied in the direction of applying stable torsion to test the strength of materials, can solve the problems of low test accuracy and small range of test objects, and achieve the effects of wide application range, convenient operation, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below in conjunction with accompanying drawing:

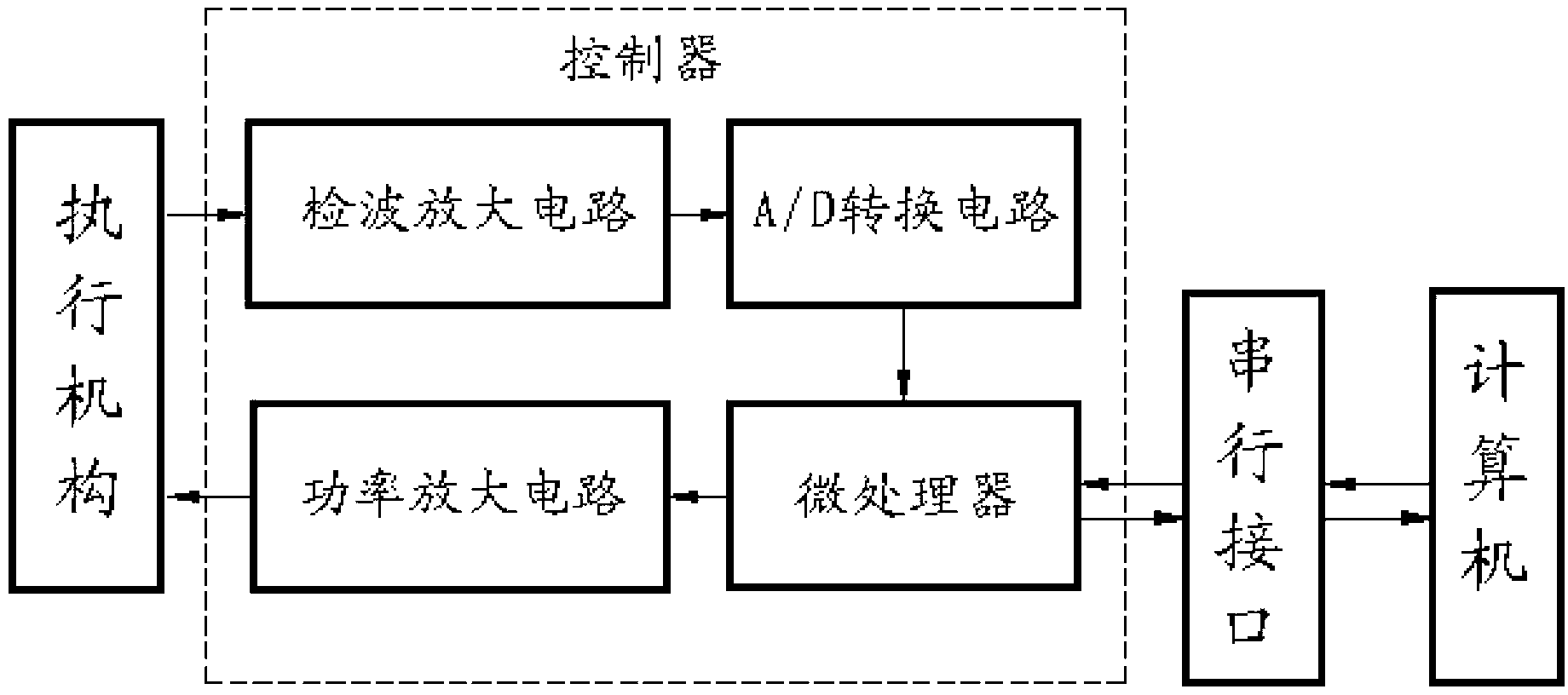

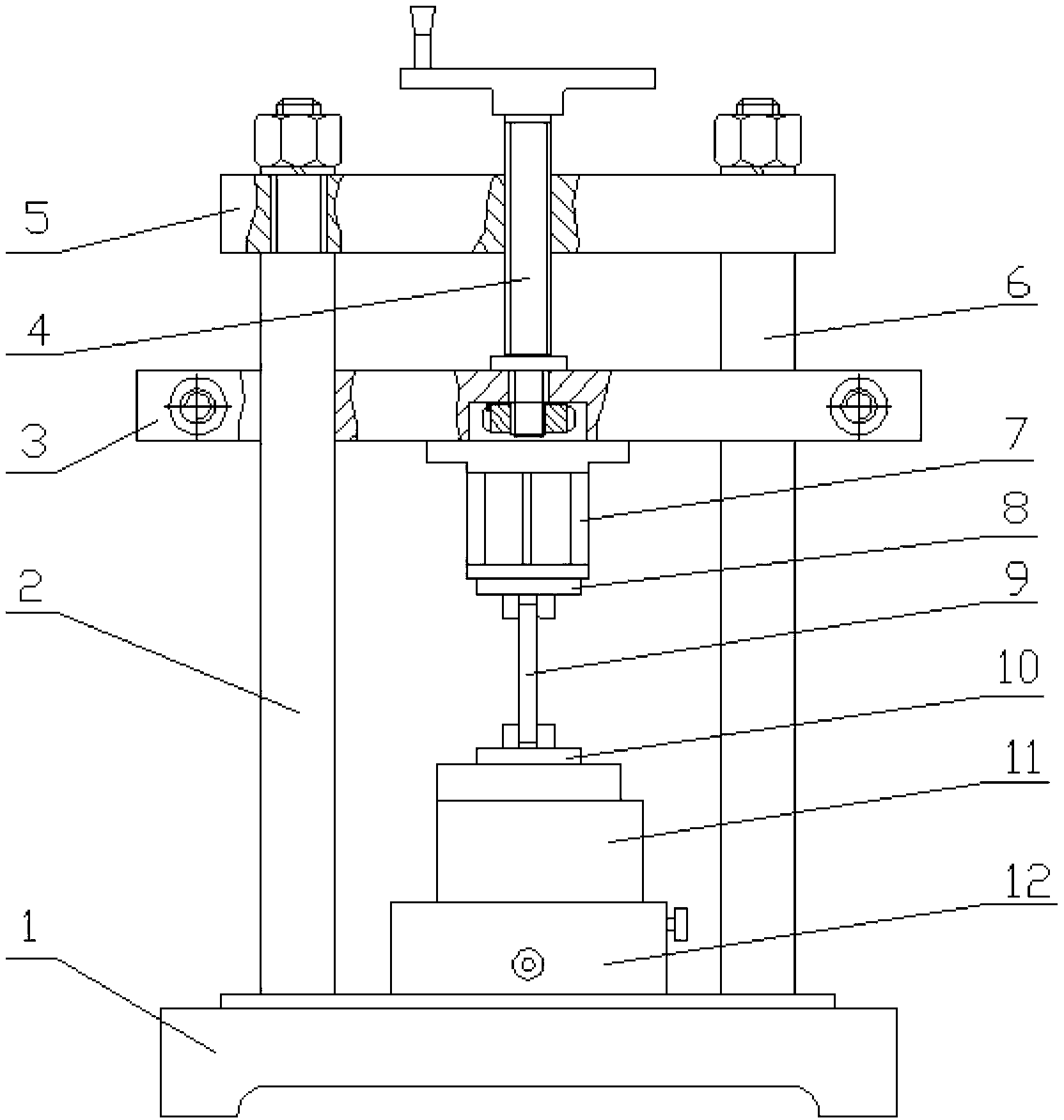

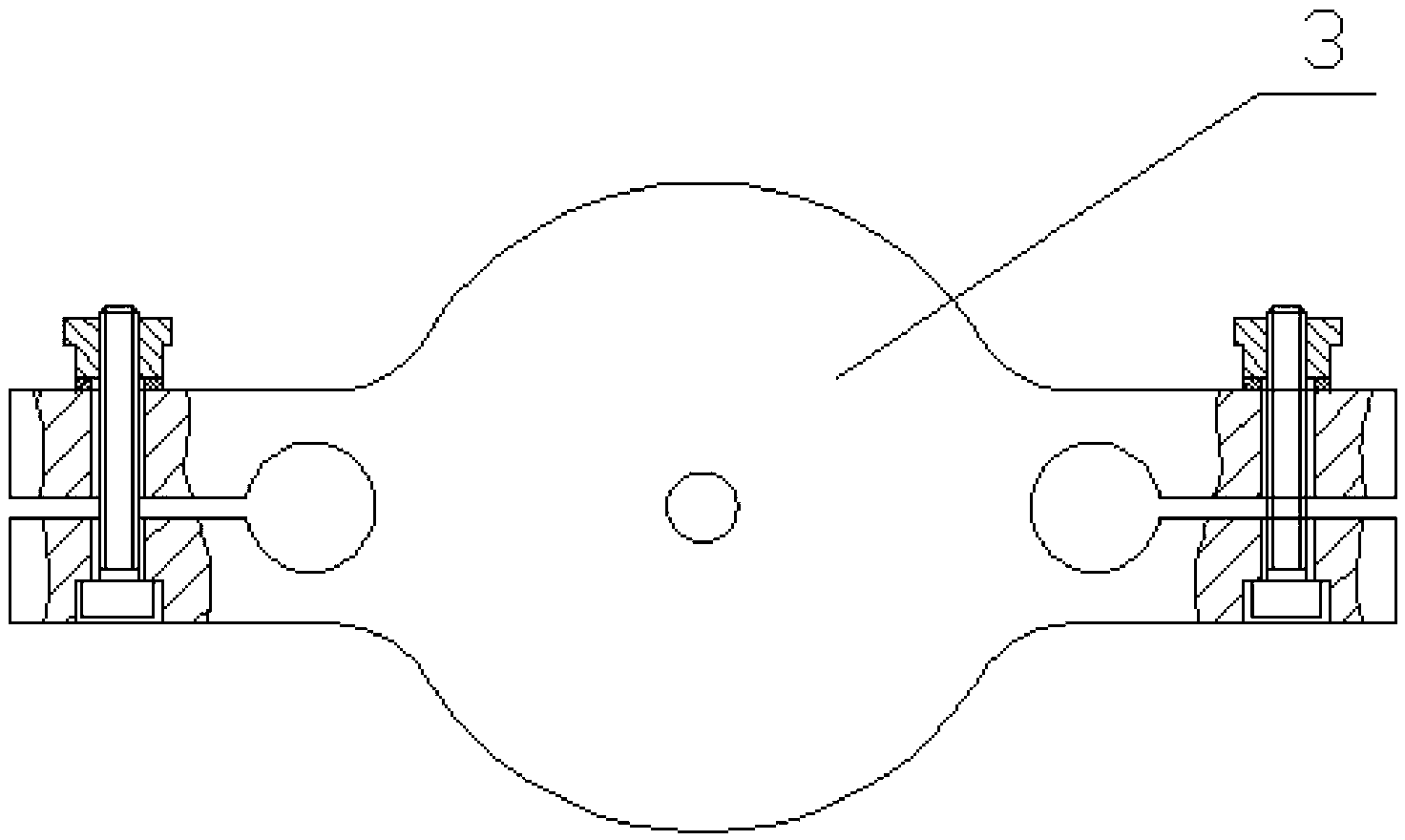

[0036] refer to figure 1 , The micro-torsion test platform of the present invention is composed of a control part and an actuator. The control part includes a computer and a controller, and the test software is installed on the computer for setting test parameters and analyzing test data; the controller includes a microprocessor, a power amplifier circuit, a detection amplifier circuit, and an A / D conversion circuit. The power amplification circuit amplifies the signal generated by the microprocessor to drive the precision electronically controlled rotary table 11 to work; the detection amplifier circuit linearly amplifies the output voltage of the micro torque sensor; the A / D conversion circuit amplifies the analog voltage of the detection amplifier circuit The signal is converted into digital quantity and sent to the microprocessor for processing, and then the microprocesso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com