Multifunctional material mechanics testing machine with functions of tension torsion and pressure torsion

A material mechanics and multi-functional technology, applied in the direction of applying stable torsion to test the strength of materials, analyzing materials, scientific instruments, etc., can solve the problem that the real test data of tension and compression torsion cannot be obtained, and the lack of tension and compression torsion test functions And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

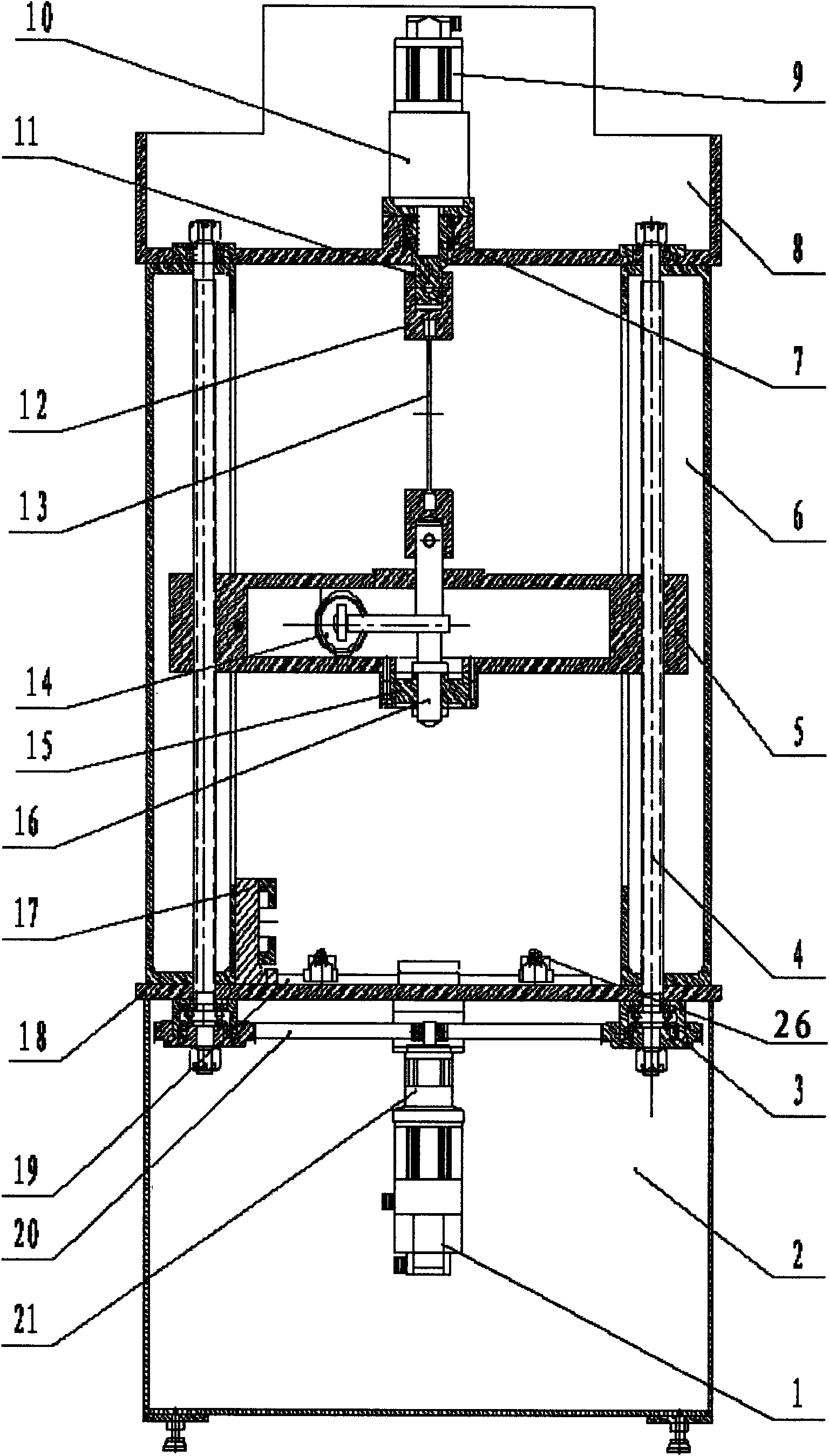

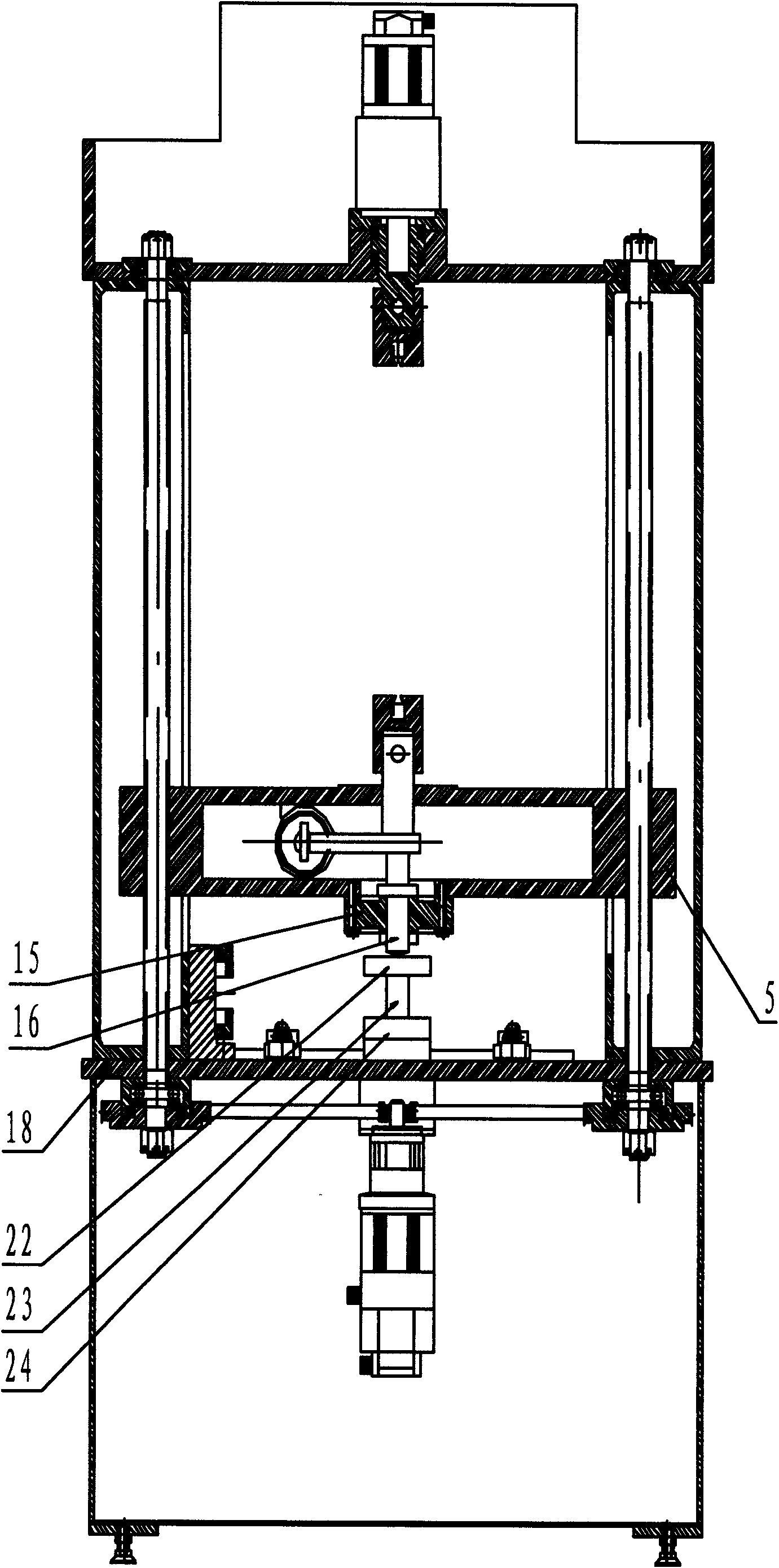

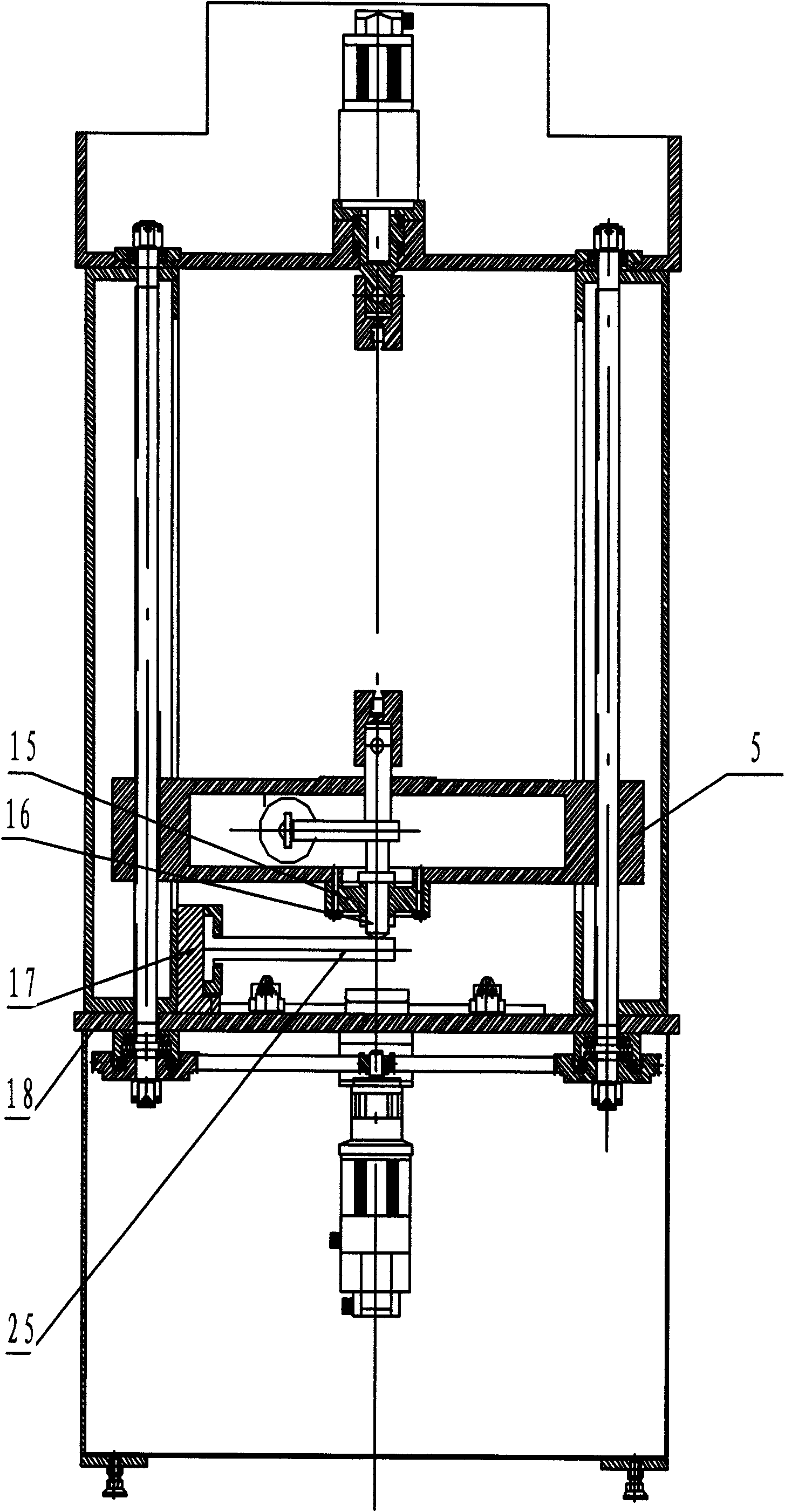

[0019] Example 1 Tensile torsion test

[0020] The multi-functional material mechanics testing machine reference of this embodiment has tension torsion and compression torsion functions figure 1 , form a fixed frame by casing 2, workbench 18, column 6 of left and right two hollow cores, upper beam 8. Leading screw 4 passes workbench 18, column 6, middle beam 5 and upper beam 8, and the fixing mode of leading screw 4 two ends makes it can rotate around the axis of self and can not move up and down. The leading screw 4 is connected with the middle beam 5 by threads. After the lifting motor 1 is decelerated by the lifting reducer 21, the synchronous belt 20 drives the left and right two synchronous pulleys 3 to rotate, and the two synchronous pulleys 3 drive the left and right two lead screws 4 to rotate. After the motor 1 is decelerated by the lifting reducer 21, under the control of the electric control mechanism, the lead screw 4 can be rotated slowly at a speed below 0.1 r / ...

Embodiment 2

[0023] Example 2 Compression torsion test

[0024] The difference between this embodiment and embodiment 1 is that starting the lifting motor 1 drives the middle beam 5 to move upward at a slow speed, and at the same time, the torsion motor 9 drives the hanging column 11 to rotate at a slow speed, so that the compression torsion test can be carried out.

Embodiment 3

[0025] Example 3 Tensile Test

[0026] The difference between this embodiment and embodiment 1 is that only the lifting motor 1 is started to move the middle crossbeam 5 slowly downwards, the torsion motor 9 is not started, the test piece 13 is stretched or even broken after being stressed, and the pulling and pressing rod 16 will pull the tension The data is transmitted to the tension and pressure sensor 15, and the tension and pressure sensor 15 senses the magnitude of the tension and sends the data to a computer for data processing and image display.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com