Torque test device

A technology of torque testing and clamping devices, applied in measuring devices, force/torque/power measuring instruments, instruments, etc., can solve problems such as difficult batch measurement, fatigue, and insufficient pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

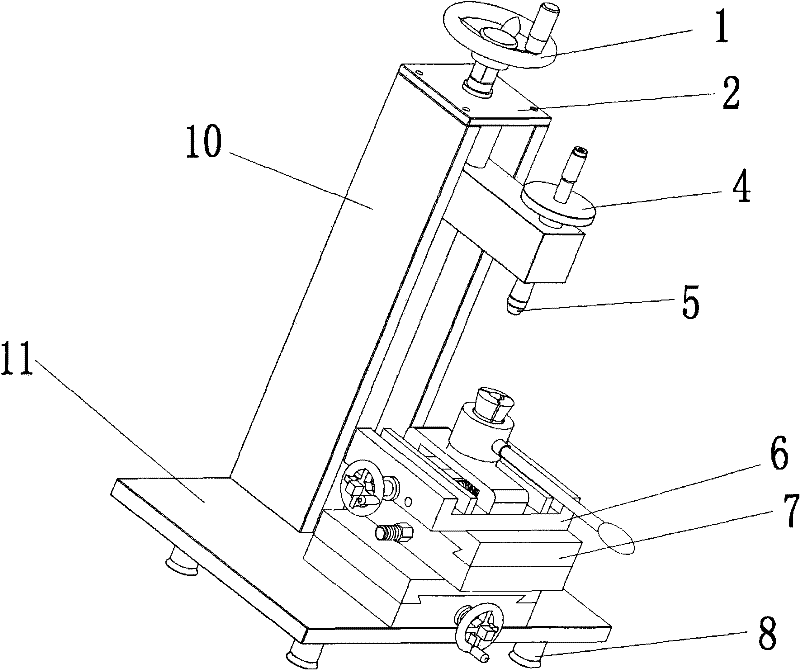

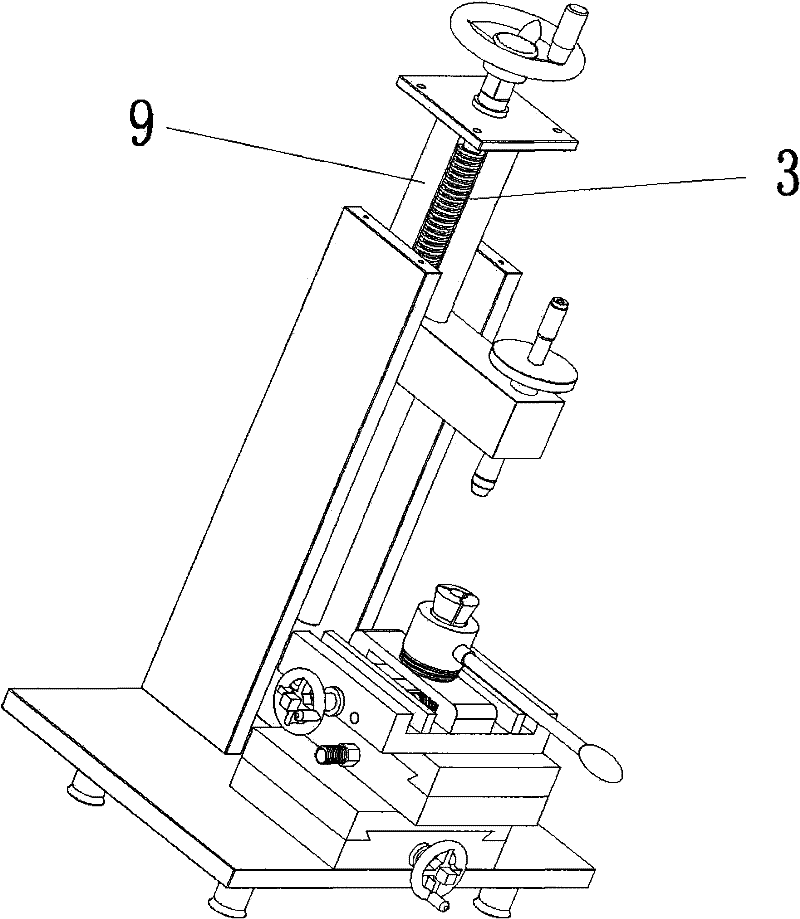

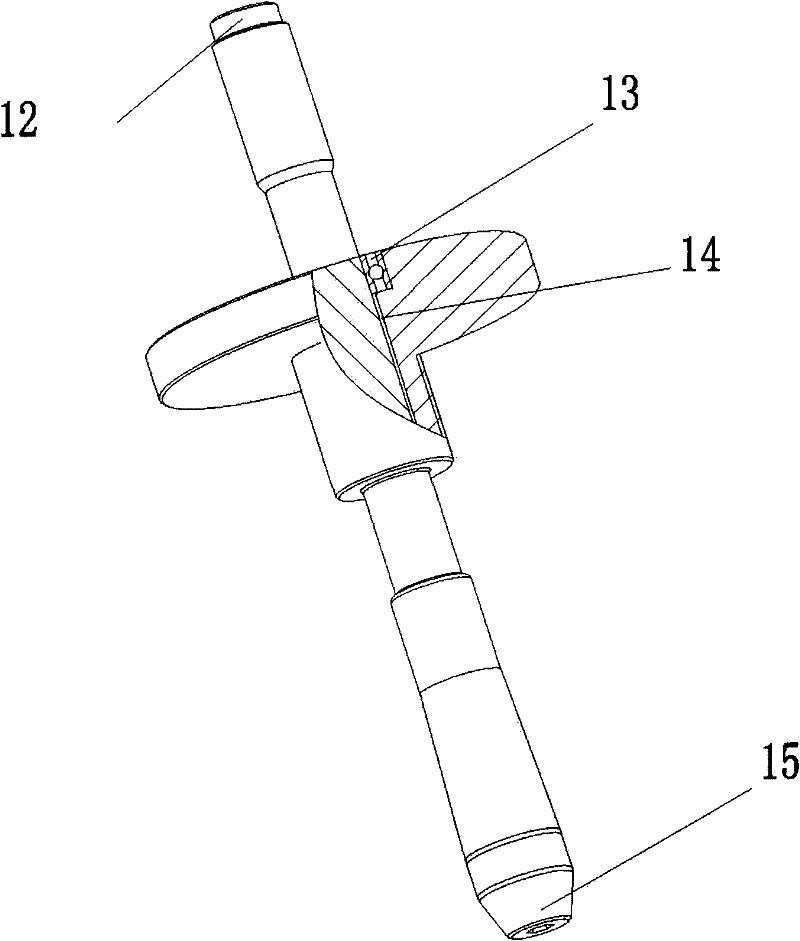

[0018] Such as figure 1 As shown, a torsion testing device includes a base 11, a clamping device 6, a torsion measurement unit, an XY adjustment unit 7 and a Z adjustment unit. The clamping device is arranged on the XY adjustment unit 7 for clamping the object to be tested; the torque measurement unit is arranged on the Z adjustment unit, and the torque measurement unit includes a bit connector 15 , a torque meter joint 12 and a transmission shaft 5 . Such as image 3 The shown bearing 13 uses a deep groove ball bearing, and the transmission shaft 5 adopts an interference fit sleeve on the deep groove ball bearing. There is a gap 14 between 5 and the fine-tuning nut 4, and when the transmission shaft rotates, it will not rub against the fine-tuning nut 4, which improves the accuracy of the experiment. A square mouth is set on the upper end of the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com