Inner rotor type gyro motor testing device

A technology of a gyro motor and a test device, which is applied to the measurement device, the test of mechanical parts, the test of machine/structural parts, etc., can solve the problems of low test accuracy, limited space, and large error in the non-perpendicularity between the motor shaft and the sensor, etc. To achieve the effect of simple test method, improve test accuracy, improve verticality and parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

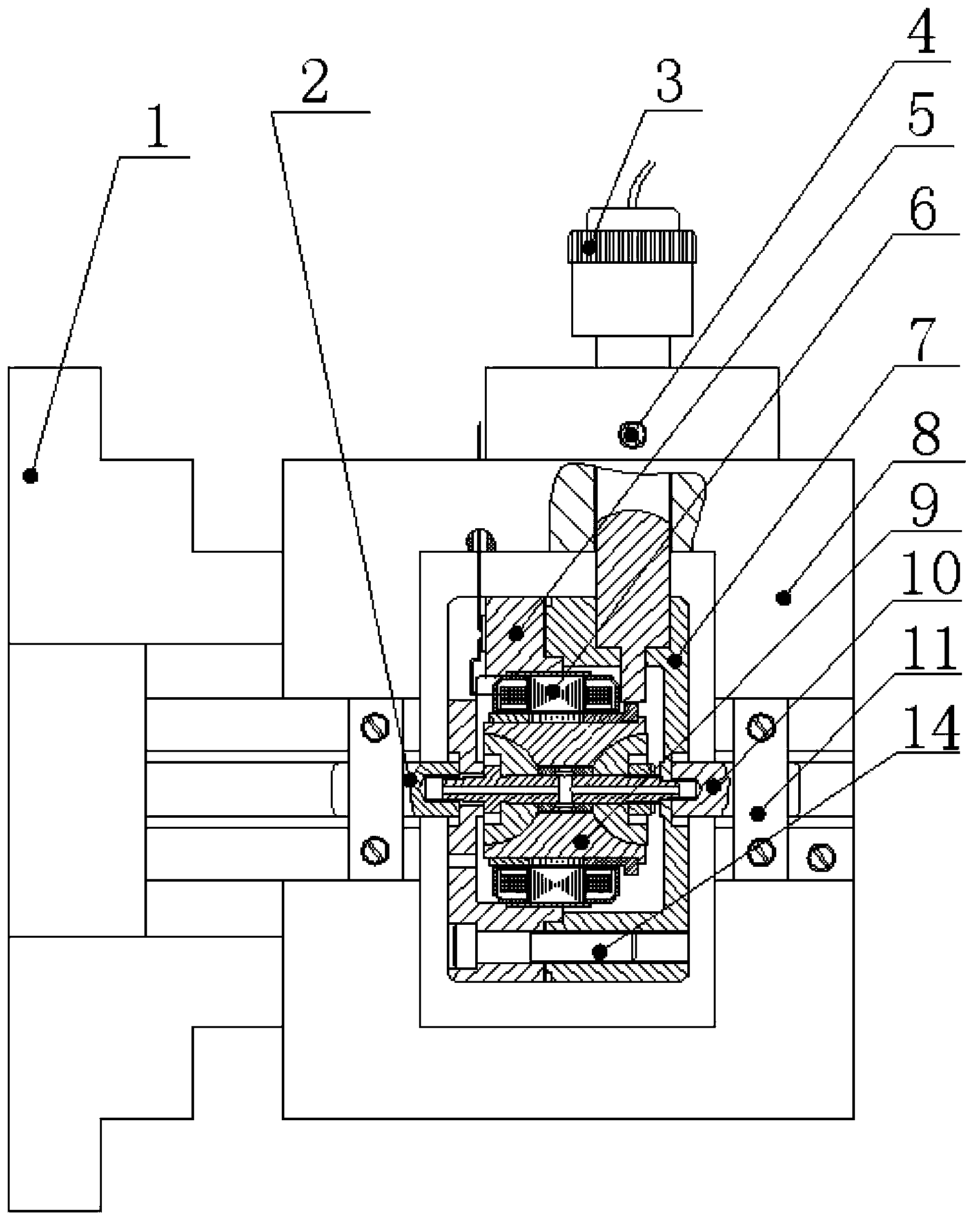

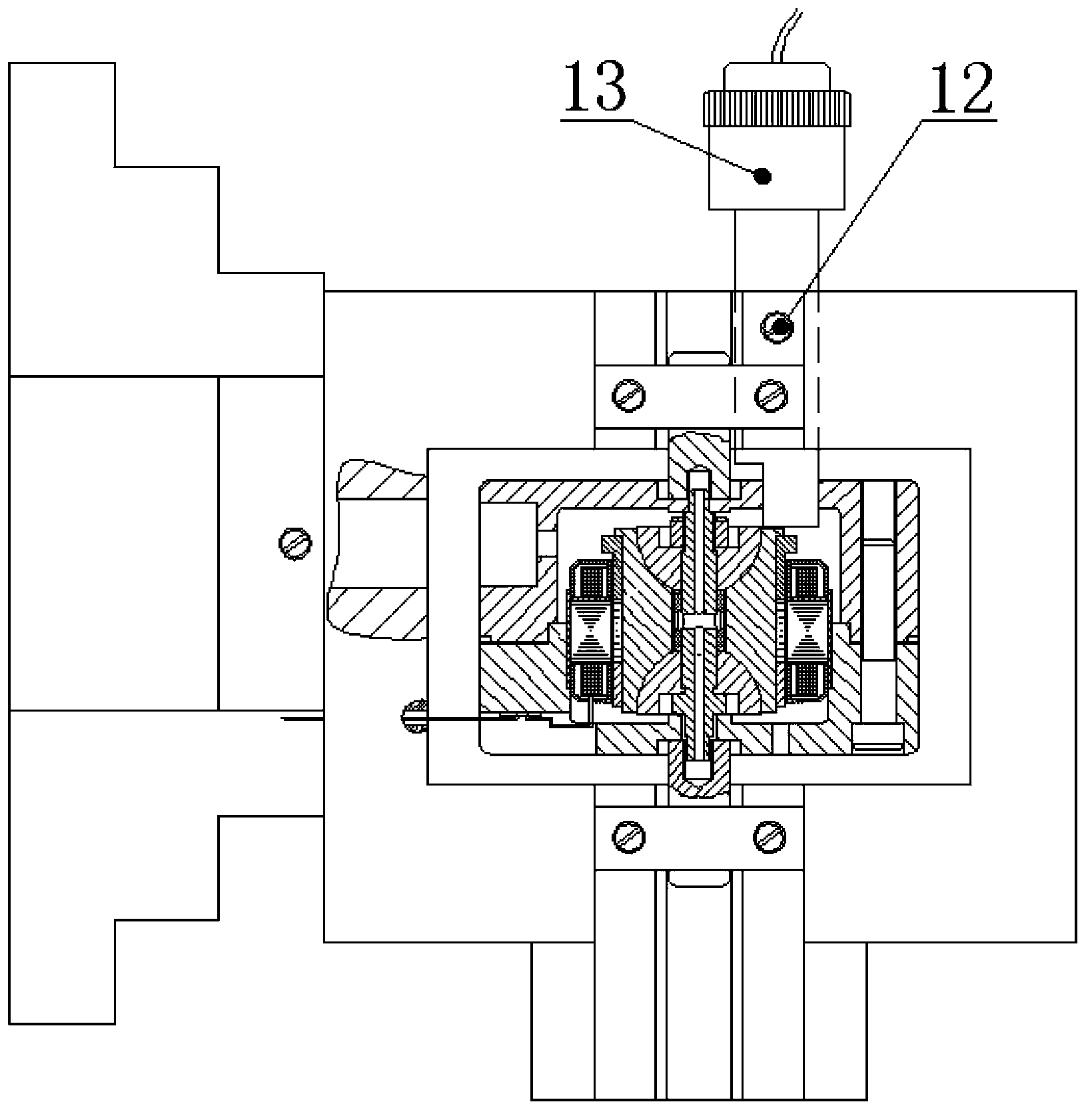

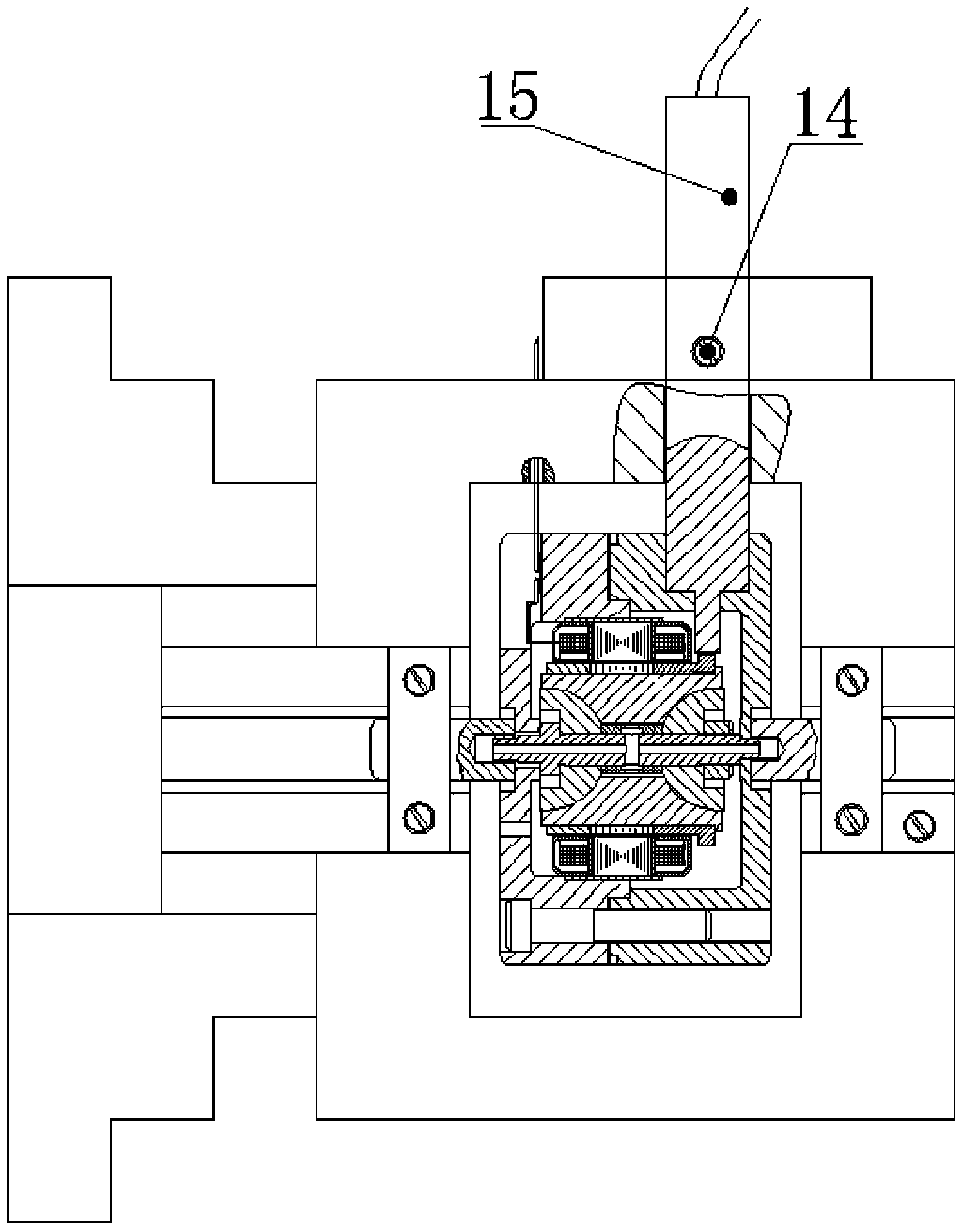

[0024] Such as figure 1 , figure 2 , image 3 As shown, the test device of the present invention includes a test bracket 8, an indexing head, a stator mounting seat, a first lock nut 2, a second lock nut 10 and two nut pressing blocks 11; the first lock nut 2 is threaded Connect the large shaft end of the gyro motor rotor 9, the second lock nut 10 is threadedly connected to the small shaft end of the gyro motor rotor 9, and the test bracket 8 and one of the nut pressing blocks 11 cooperate to form a socket for accommodating the first lock nut 2. Cylindrical cavity, the test bracket 8 and another nut pressing block 11 cooperate to form a cylindrical cavity for accommodating the second locking nut 10; The lock nut 10 is fixed on the test frame 8; the test frame 8 is clamped on the index head by the three claws 1 of the index head; the stator mounting seat is located in the test frame. Such as Figure 7 As shown, the stator mounting seat includes the upper stator mounting se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com