An assembly method of a vortex speed limiter for a high temperature gas-cooled reactor

A technology of a high temperature gas-cooled reactor and an assembly method, which is applied in the directions of electromechanical devices, electrical components, and the manufacture of motor generators, etc., can solve the problems that the installation methods cannot meet the assembly requirements, the components are scrapped, and the permanent magnets attract each other, and achieve stable and stable fixation. The effect of avoiding scrap parts and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

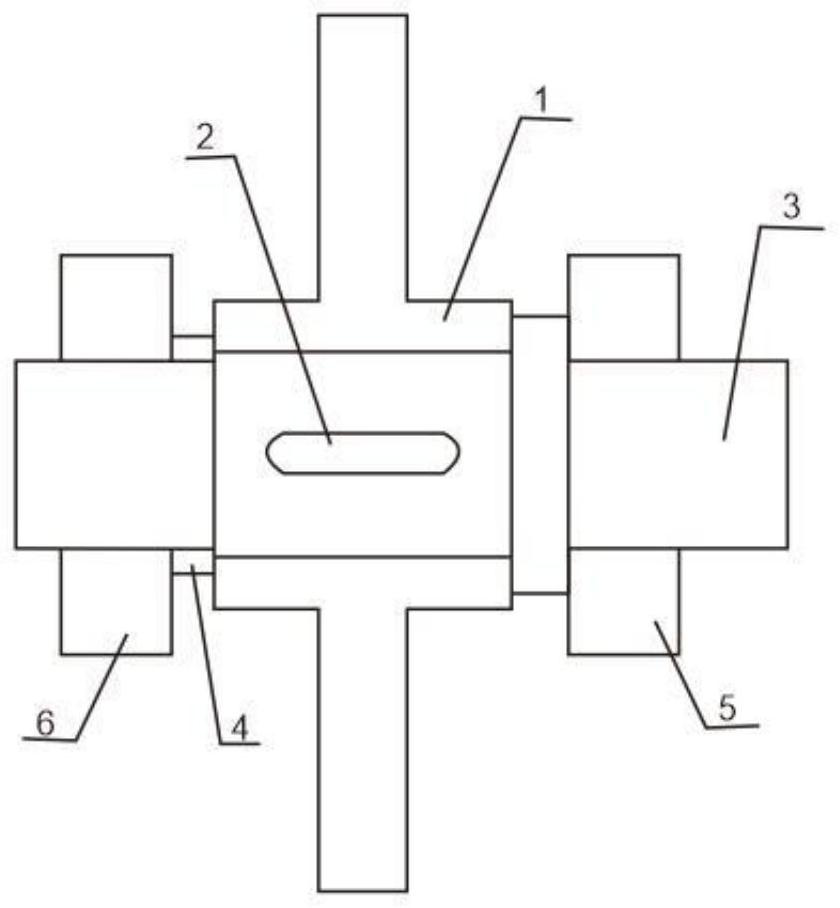

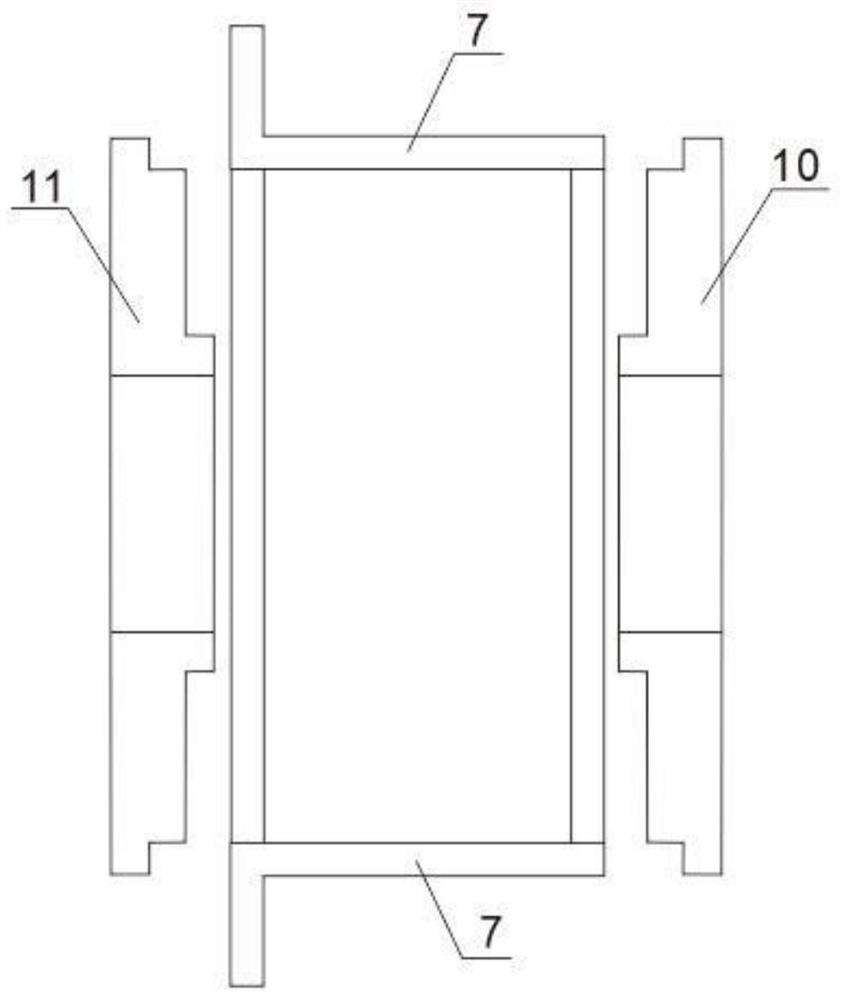

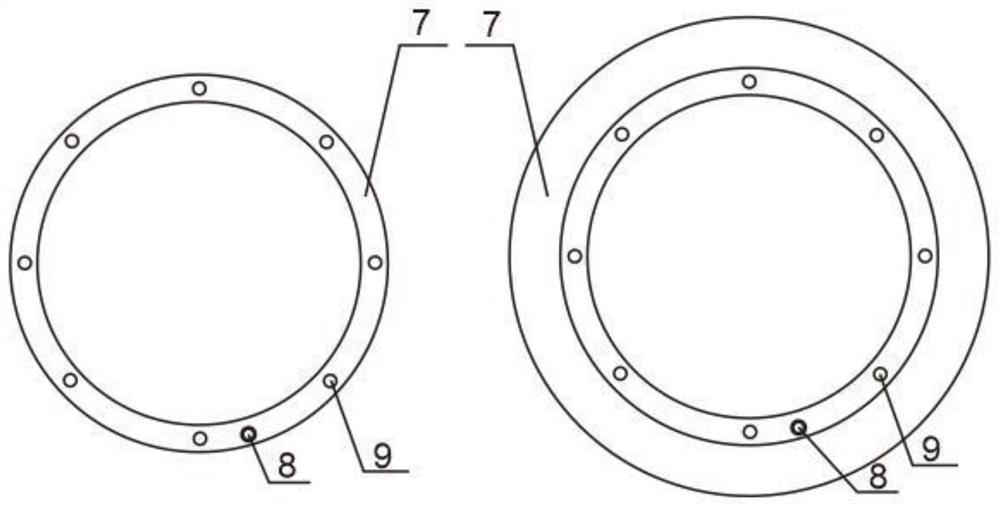

[0038] like Figure 1-10 As shown in the figure, the assembly method of the high temperature gas-cooled reactor eddy current speed limiter, the eddy current speed limiter on it includes a damping plate 1, a connecting flange 7, an end cover, a permanent magnet 15 and a bearing cover 20. The key groove of the damping plate 1 is provided with Flat key 2, the shaft sleeve 3 on the outside of the damping disc 1 is sleeved with the shaft sleeve 4, the outer bearing 6 is sleeved on the shaft sleeve 4, the inner bearing 5 is sleeved on the shaft 3 on the inner side of the damping disc 1, and the connecting flange 7 is sleeved on the damping disc 1 and end caps are arranged at both ends of the connecting flange 7. The end caps include an inner end cap 10 and an outer end cap 11. The inner end of the connecting flange 7 is provided with a positioning hole 8 and a fixing hole 9 corresponding to the inner end cap 10. The outer end of the flange 7 is provided with a positioning hole 8 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com