Prefabricated concrete structure wall simple connector

A prefabricated concrete and structural wall technology, applied to walls, building components, building structures, etc., can solve problems such as inability to install, increase the difficulty of installing structural walls on the construction site, and collisions between upper and lower steel bars, so as to improve efficiency, ensure project quality and Structural stability and the effect of increasing the working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

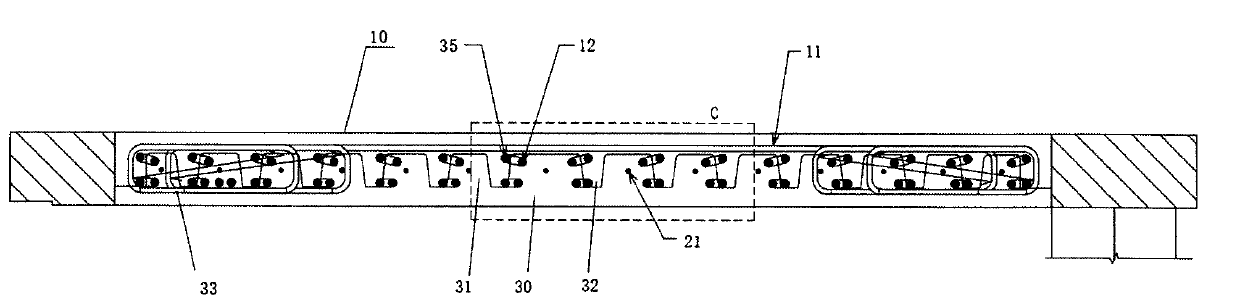

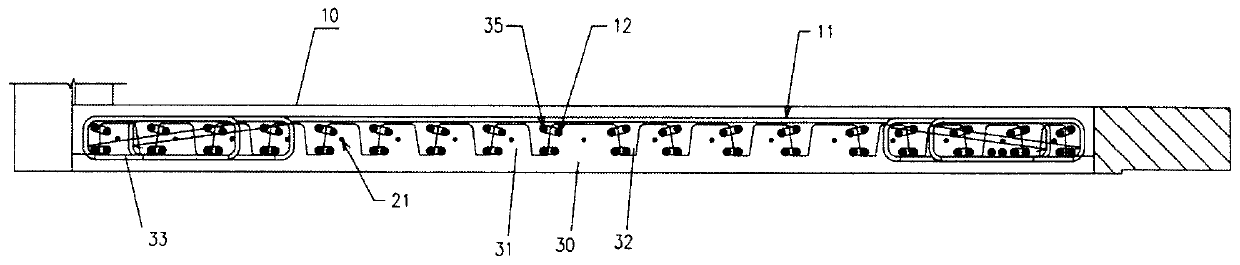

[0020] Below in conjunction with the best embodiment shown in the accompanying drawings, it will be further described in detail.

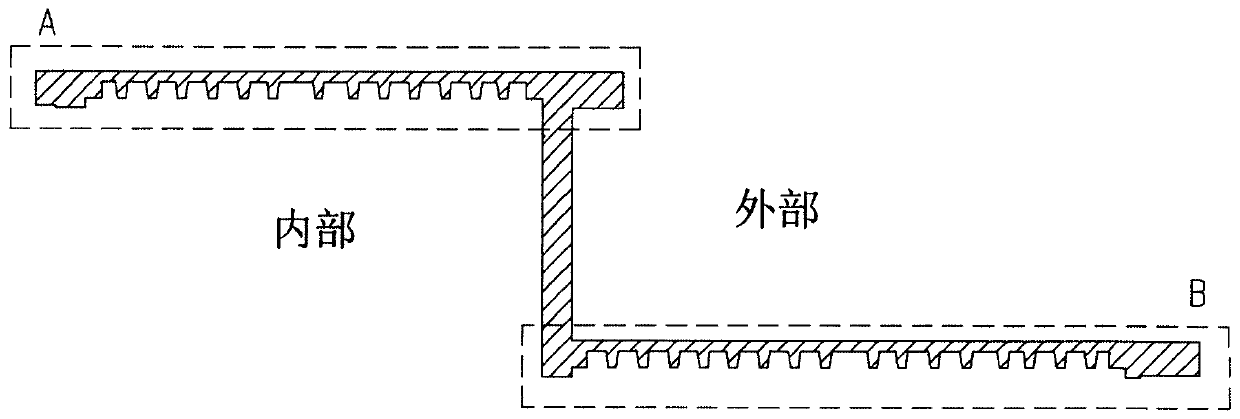

[0021] Please refer to Figure 1 to Figure 5 , an embodiment of the present invention provides a simple interface of a precast concrete structure wall, which is used to connect the precast concrete structure wall and the bottom load-bearing member. The bottom load-bearing member may be a beam, a column, or other structures, which may be prefabricated or cast-in-place, which is not limited herein.

[0022] In the embodiment of the present invention, the interface may include: an inwardly recessed semi-prefabricated connection opening 30 provided at the lower end of the precast concrete structural wall 10, and a reserved exposed steel bar 21 provided at the top of the bottom load-bearing member 20; The inner wall of the semi-prefabricated connection port 30 is a concave-convex surface, with a plurality of concave positions 31 and a plurality of conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com