Load testing system for high-speed motor

A load test, high-speed motor technology, applied in the direction of motor generator testing, etc., can solve the problems of not meeting the test requirements of 12000rpm high-speed motor, unable to complete the test of high-power, high-speed motor, unable to meet the test requirements of high-speed motor, etc., to prevent The effect of foreign body splashing, weight reduction, and convenient adjustment of concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

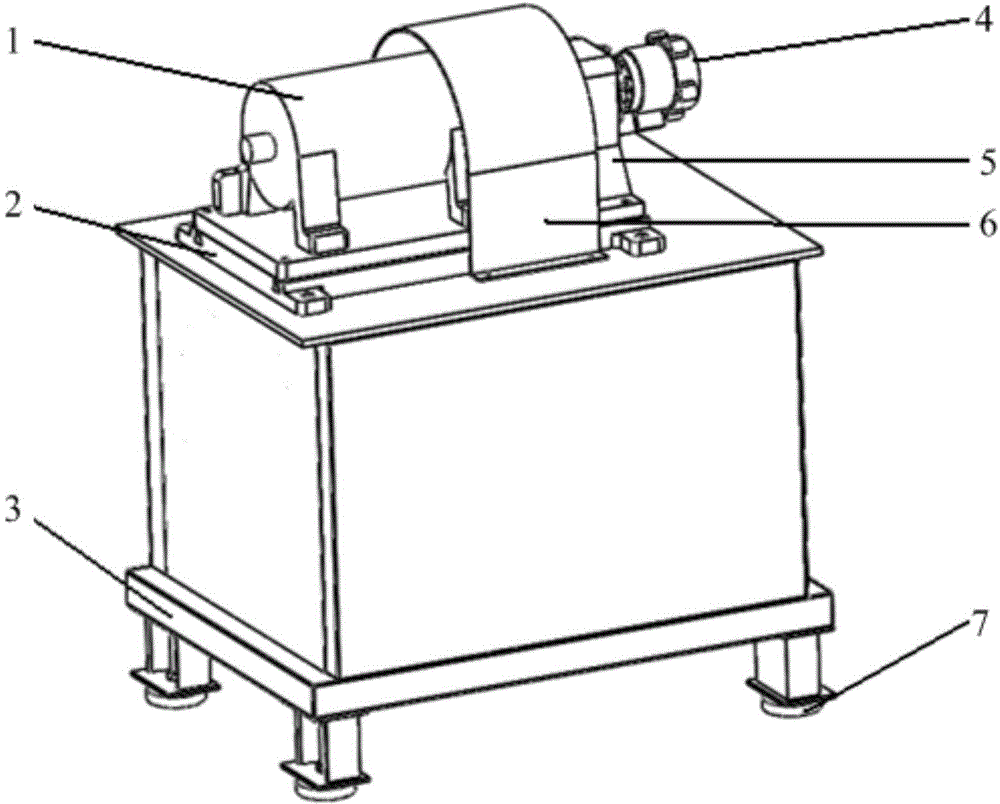

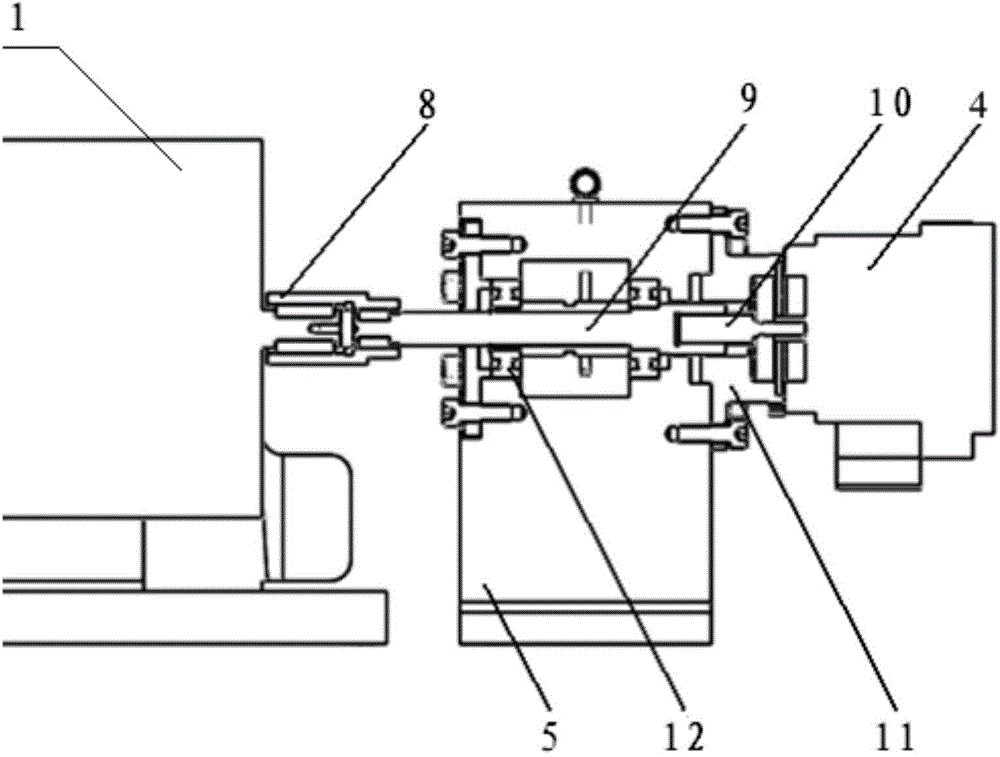

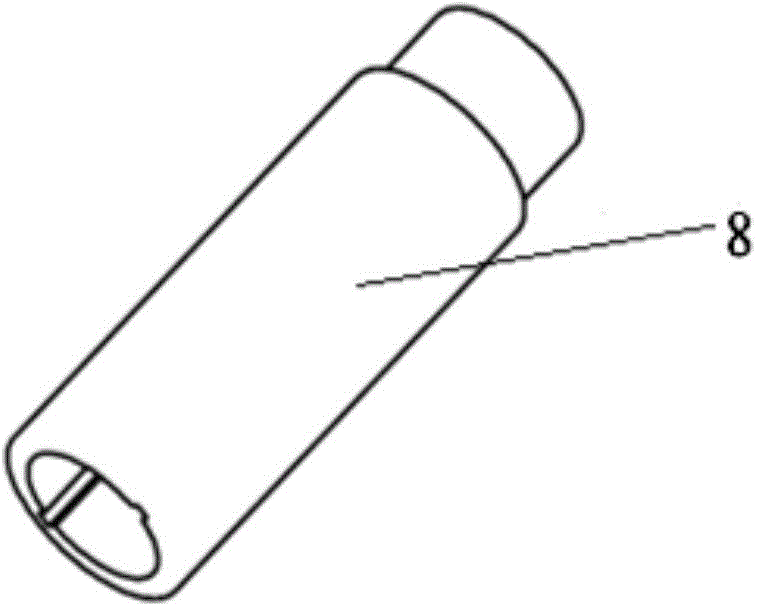

[0021] Such as figure 1 As shown, a kind of high-speed motor test system provided by the present invention includes dynamometer 1, T-type platform 2, test bench 3, tested motor 4, bearing seat 5, protective cover 6, shock absorbing pad iron 7, joint A shaft joint 8, a connecting shaft 9, an adapter shaft 10, a mounting flange 11, a high-speed bearing 12 and a water cooling system. The bottom of the test bench 3 is provided with 4 supporting legs, and a shock-absorbing pad iron 7 is installed on each of the 4 supporting legs. The upper surface of the test bench 3 is fixedly connected to the T-shaped platform 2 by bolts. One end of the upper surface of the T-shaped platform 2 is fixedly connected to the dynamometer 1 by bolts; the other end of the upper surface of the T-shaped platform 2 is fixedly connected to the bearing seat 5 by bolts.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com