Servo motor testing system for industrial robot

A technology of industrial robots and servo motors, applied in the direction of motor generator testing, instruments, measuring electricity, etc., can solve the problems of increased cycle, insufficient pertinence, and high robot prices, and achieve low cost, wide adaptability, and guaranteed test intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

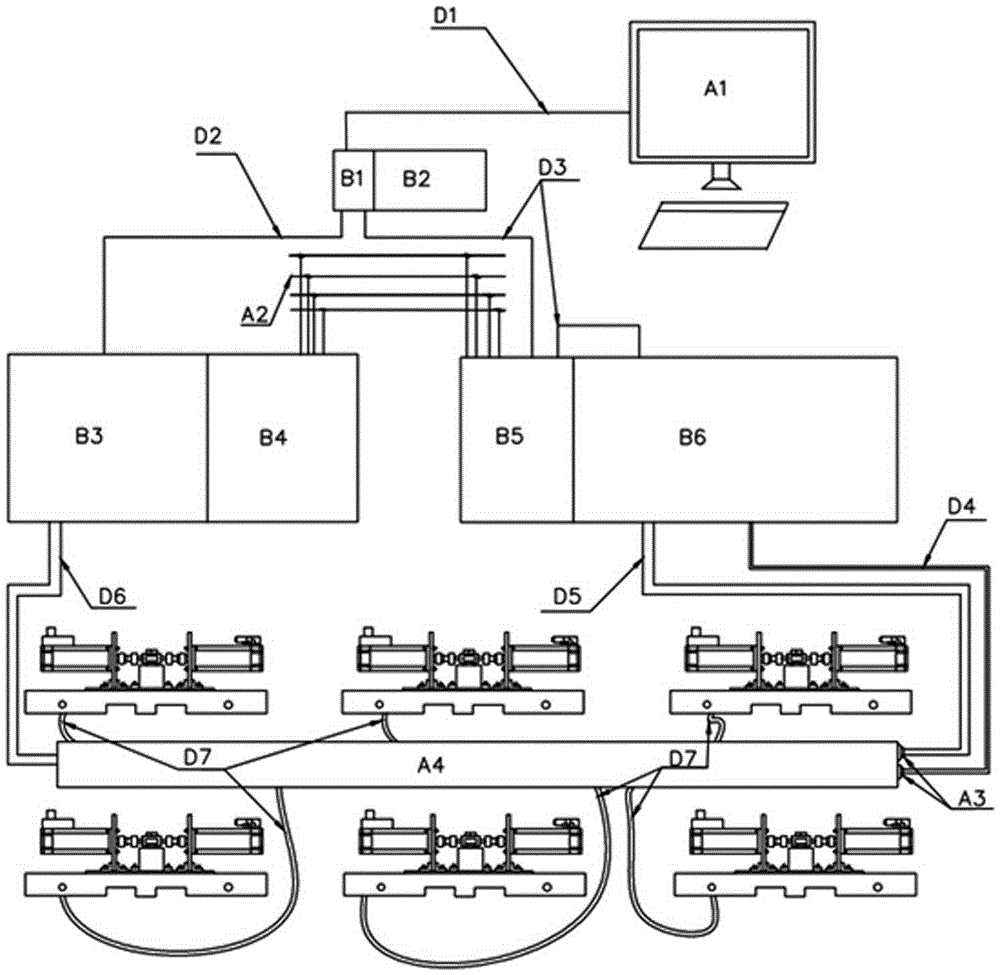

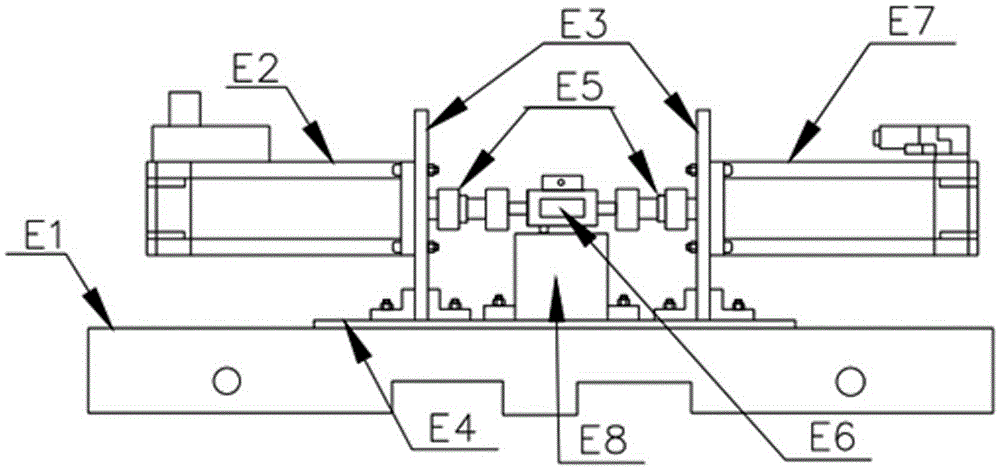

[0018] refer to Figure 1-2 , the specific embodiment adopts the following technical solutions: industrial robot servo motor test system, including electrical parts and mechanical test bench, the electrical part is connected to the mechanical test bench, and the electrical part is composed of computer A1, 380V alternating current A2, robot heavy-duty plug A3 , cable trunking A4, X20PLCB1, X20DI module B2, inverter module B3, rectifier module B4, AcoposMulti power supply module B5 and AcoposMulti inverter module B6, the mechanical test bench consists of installation base E1, AC power dynamometer E2, installation Flange E3, installation track E4, elastic coupling E5, torque speed measuring instrument E6, servo motor to be tested E7 and torque speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com