Testing method for iron core loss of alternating-current permanent magnet motors

A technique for permanent magnet motors and testing methods, which is applied to measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve problems such as the inability to consider the influence of the iron core manufacturing process, and difficulty in equipment adjustment, so as to avoid calculation of instrument parameters and Effects of adjustment, test cost savings, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

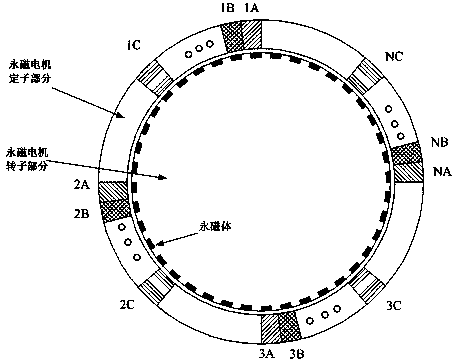

[0024] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited to this. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the technical solution of the present invention. in the scope of protection.

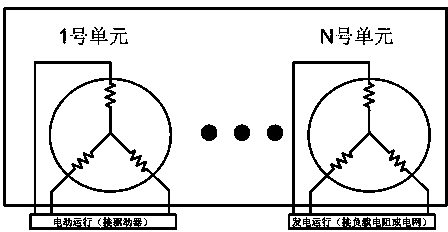

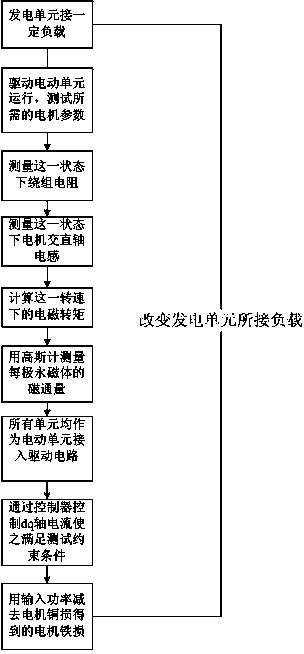

[0025] Such as image 3 As shown, the test method of the multi-phase multi-unit permanent magnet synchronous motor stator core loss without mechanical load proposed by the present invention specifically comprises the following steps:

[0026] Step 1: The generator unit is connected to the load resistor or the load grid. When connected to the load grid, the control driver is turned off first.

[0027] Step 2: Connect the motor unit to the driver, and control the driver to start running. Test the motor speed, three-phase winding cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com