Hub motor on-load EMC performance test system

A hub motor and testing system technology, which is applied in the direction of motor generator testing, measuring electricity, measuring devices, etc., can solve the problems of high testing cost, unacceptable, difficult to purchase, etc., and achieve the effect of saving testing cost and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

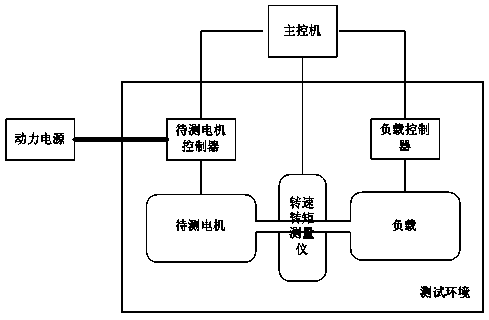

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

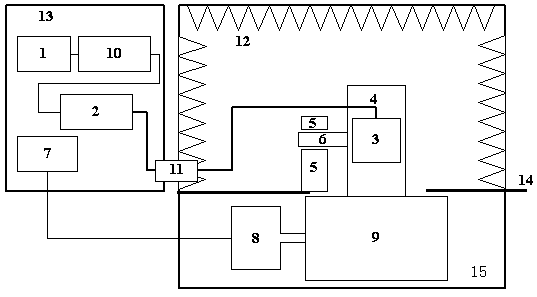

[0031] Example 1, such as image 3 As shown, the present invention tests the electromagnetic compatibility performance of the hub motor (including the hub motor and the wheel), and the test environment layout: power supply 1, hub motor controller 2, drum controller 7 and linear impedance stabilization network (LISN) 10 is arranged in a shielded control room 13 (such as a metal shielded room), and the hub motor 3, wheel 4, fixing device 5, and shaft 6 are arranged in an anechoic room 12 (such as a layer of electromagnetic wave-absorbing material is provided on the inner surface of the metal shielded room) On the ground 14 of the shielding room), the drum motor 8 and the drum 9 are arranged in the drum shielding room 15 (which has been well shielded during design and construction) under the ground 14 of the anechoic chamber 12 . The output of the power supply 1 is connected to the in-wheel motor controller 2 after passing through the linear impedance stabilization network 10, an...

Embodiment 2

[0032] Example 2, such as Figure 4As shown, when the present invention tests the magnetic compatibility performance of the hub motor system including the hub motor, the hub motor controller and the power cable, the test environment layout: the power supply 1 and the drum controller 7 are arranged in the shielded control room 13, and the hub motor The controller 2, the hub motor 3, the wheel 4, the fixing device 5, the shaft 6 and the linear impedance stabilization network (LISN) 10 are arranged on the ground 14 of the anechoic chamber 12, and the drum motor 8 and the drum 9 are arranged in the anechoic chamber 12 In the drum shielded room 15 below the ground 14. The output of the power battery 1 enters the anechoic chamber 12 through the wall plate connector 11 of the anechoic chamber 12 through a well-shielded cable, and is connected to the hub motor controller 2 after passing through the linear impedance stabilization network 10, and the output of the hub motor controller 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com