High-power brushless double fed motor variable frequency speed regulation system and control method

A frequency conversion speed regulation and electric motor technology, which is applied in the direction of single motor speed/torque control, AC motor control, control system, etc., can solve the problem that the motor cannot realize full speed regulation, and achieve high reliability, high system reliability, Maintain Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

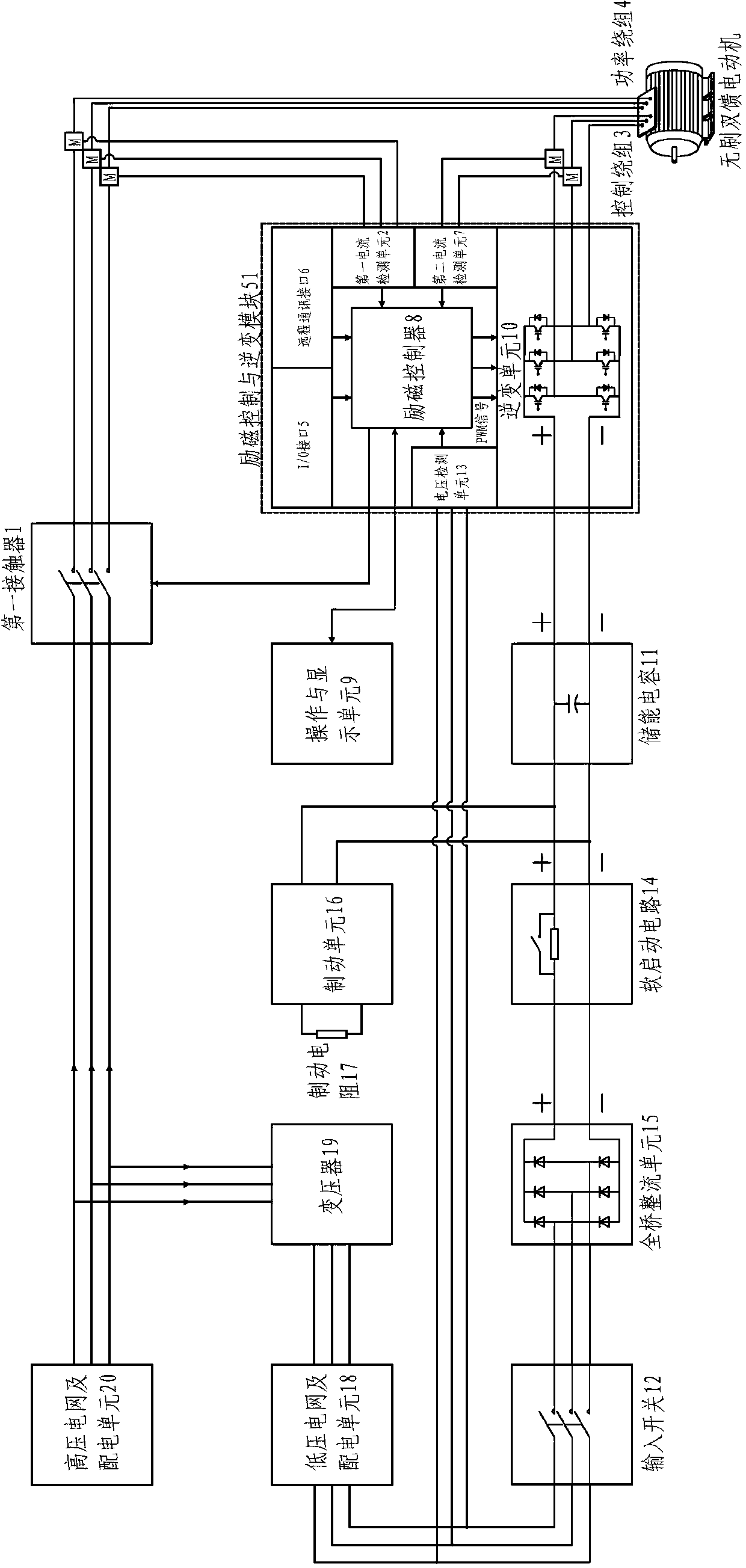

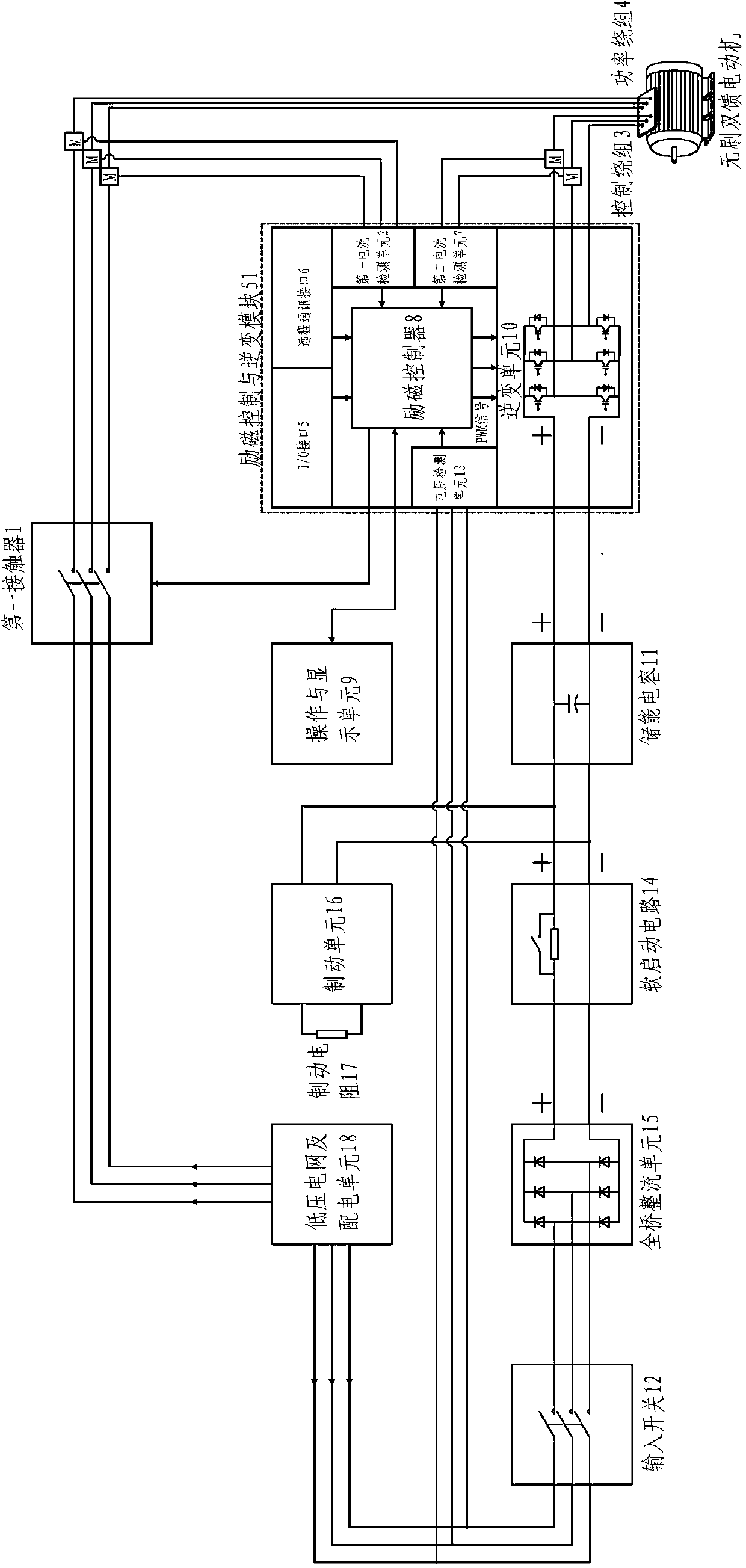

Embodiment 1

[0047] Embodiment 1 is suitable for the speed regulation control of high-power brushless double-fed motors above 1000kw, and embodiment 2 is suitable for the speed regulation control of high-power brushless double-fed motors between 300kw-1000kw, and the control power is only 30% of the maximum power of the motor. Low cost has strong economic feasibility.

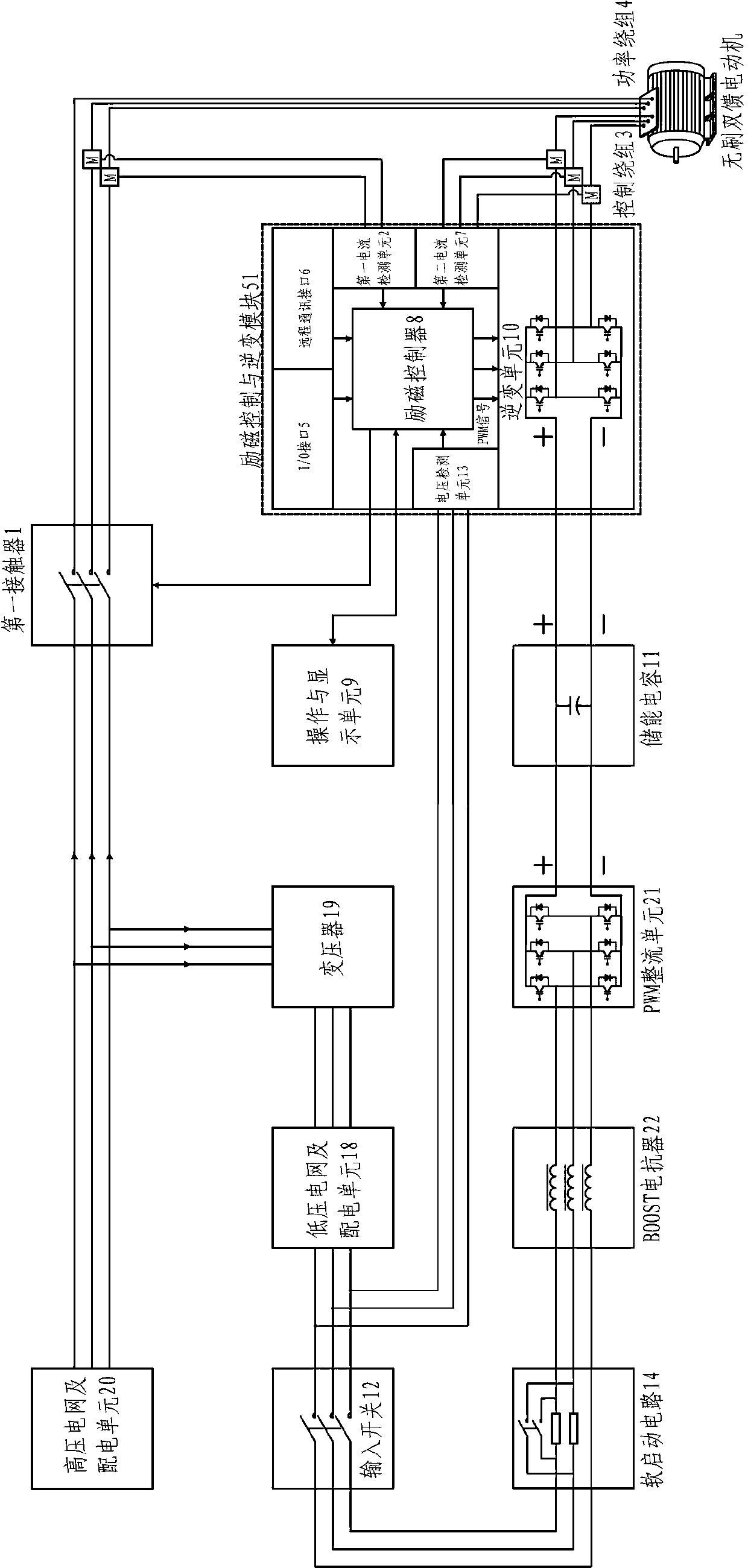

[0048] Such as image 3 As shown, the third embodiment includes an excitation controller 8, an inverter unit 10, a first current detection unit 2, a second current detection unit 7, a voltage detection unit 13, an energy storage capacitor 11, a PWM rectification unit 21, and a BOOST reactance 22, soft start circuit 14, input switch 12, low-voltage grid power distribution unit 18, transformer 19, high-voltage grid power distribution unit 20, first contactor 1 and operation and display unit 9. Among them, the excitation controller 8, the inverter unit 10, the first current detection unit 2, the second current detection unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com