Novel power matching system of energy-saving road roller

A technology of road roller and power, applied in the field of new energy-saving road roller power matching system, can solve the problems of lack of construction performance of the whole vehicle, driving discomfort, high energy consumption and noise of diesel engine, and achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

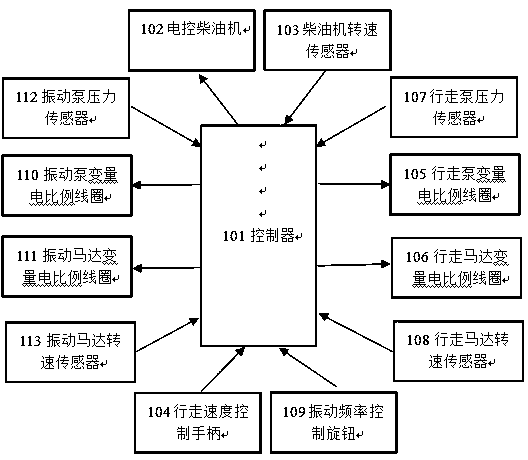

[0022] Such as figure 1 As shown, this embodiment discloses a new energy-saving road roller power matching system, which includes:

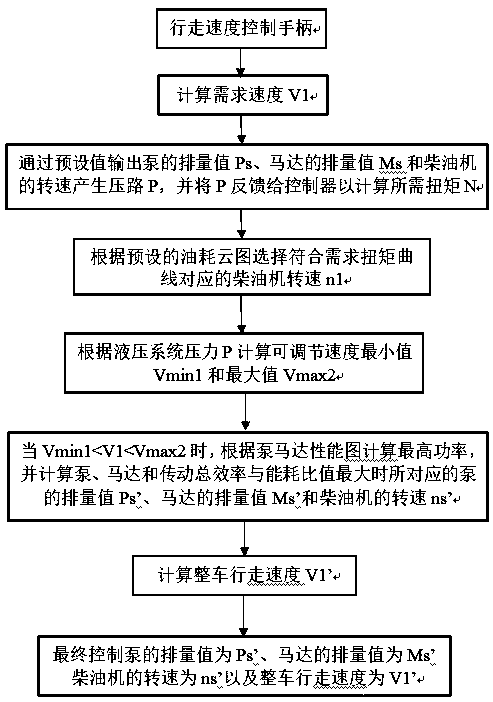

[0023] It includes a controller 101, an electronically controlled diesel engine 102, a diesel engine speed sensor 103 for detecting the speed of the electronically controlled diesel engine and generating a diesel engine speed signal, a control handle 104 for controlling the walking speed of the whole machine, and a control handle for start-stop control and drive volume respectively. Size-controlled walking pump variable electric proportional coil 105 and walking motor variable electric proportional coil 106, walking pump pressure sensor 107 for detecting walking pump pressure and generating walking pump pressure signal, used for detecting walking motor speed and generating walking motor speed signal The speed se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com