Method and device for controlling multi-motor variable-frequency drive of belt conveyor

A belt conveyor, multi-motor technology, applied in the direction of speed adjustment of multiple motors, can solve the problem that the belt conveyor cannot automatically adapt to load changes, and achieve the effect of ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

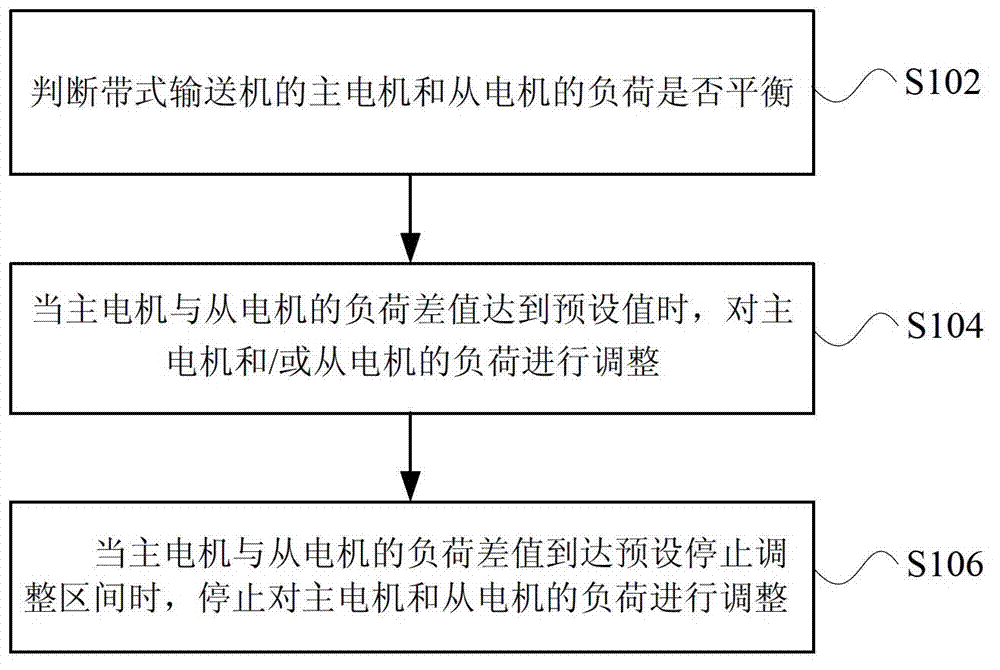

[0044] This embodiment provides a multi-motor variable frequency drive control method for a belt conveyor. It is mainly adjusted for the unbalanced state of load distribution during the start, stop and constant speed operation of the conveyor to ensure the stable operation of the equipment. Its main implementation method is as follows (this embodiment is described by taking dual motors and two-point drive as an example):

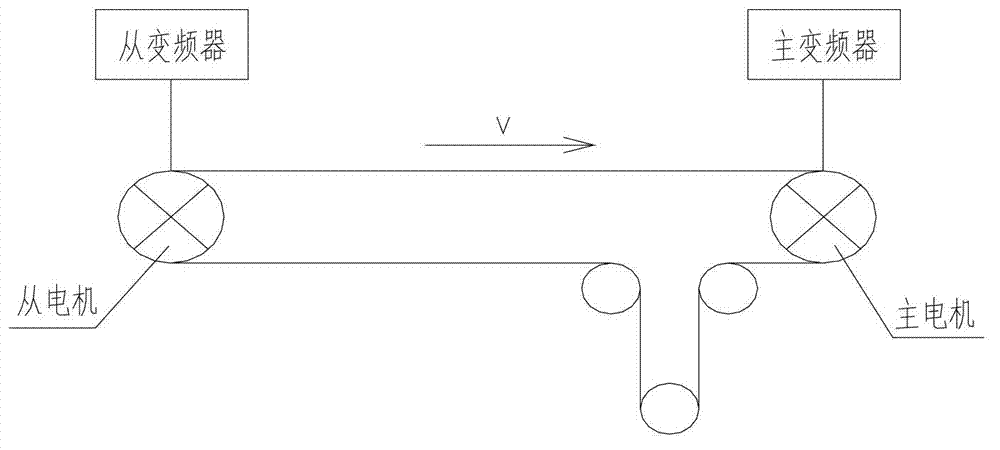

[0045] image 3 A schematic diagram of the multi-motor variable frequency drive principle of the belt conveyor according to the first embodiment of the present invention is shown. like image 3 As shown in the figure, the belt conveyor includes two motors. Among the two motors, the motor on the conveying direction side is the main control motor, the inverter controlling the motor is the main inverter, and the motor on the other side is the main control motor. From the motor, its inverter is a slave inverter.

[0046] Input the actual current data and act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com