Hydraulic control method of hydraulic motor rotating speed and device thereof

A hydraulic motor and rotational speed technology, which is applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., can solve the problems of increased human manipulation, unstable work, and poor ability of the motor to resist load fluctuations, so as to achieve fuel economy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

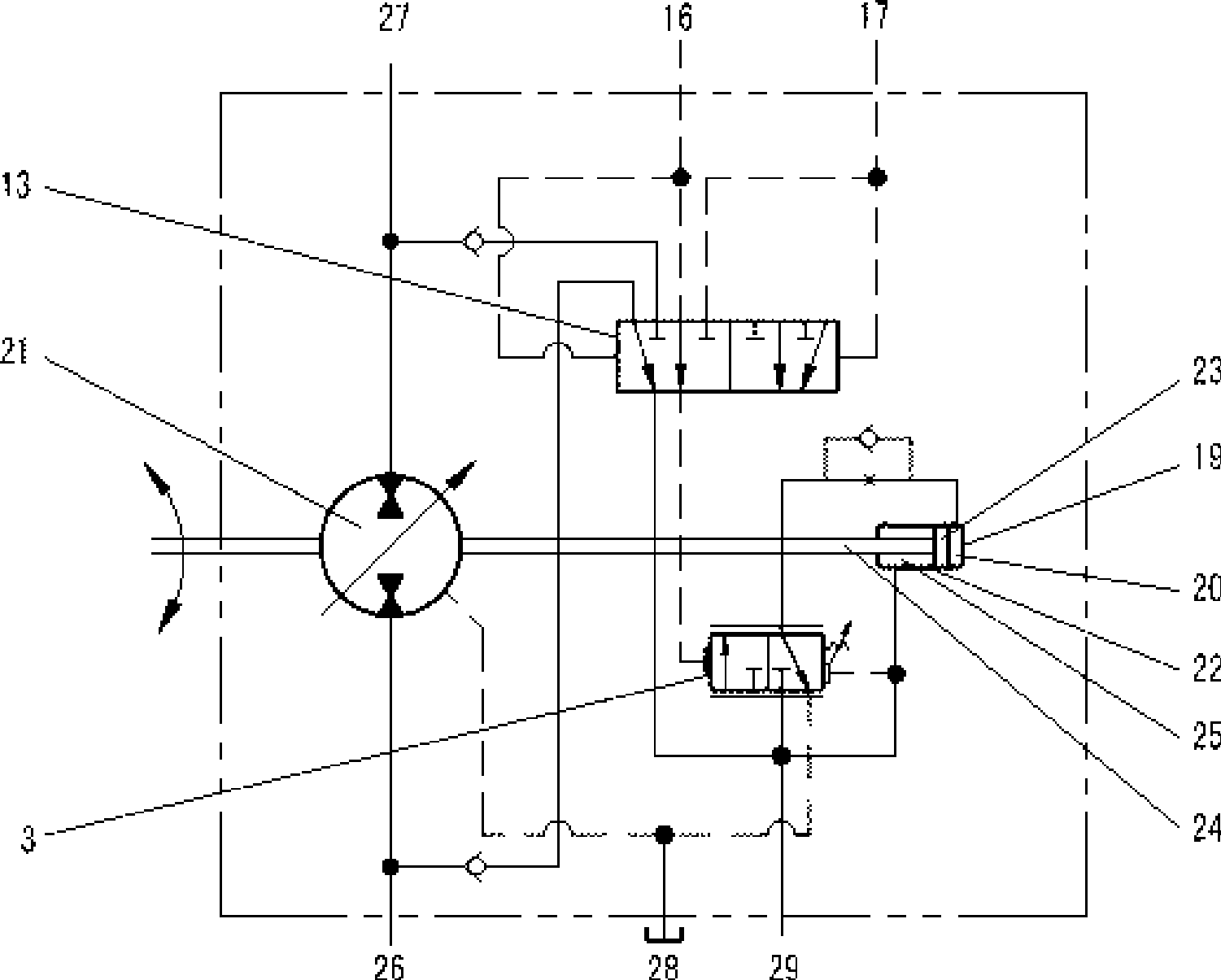

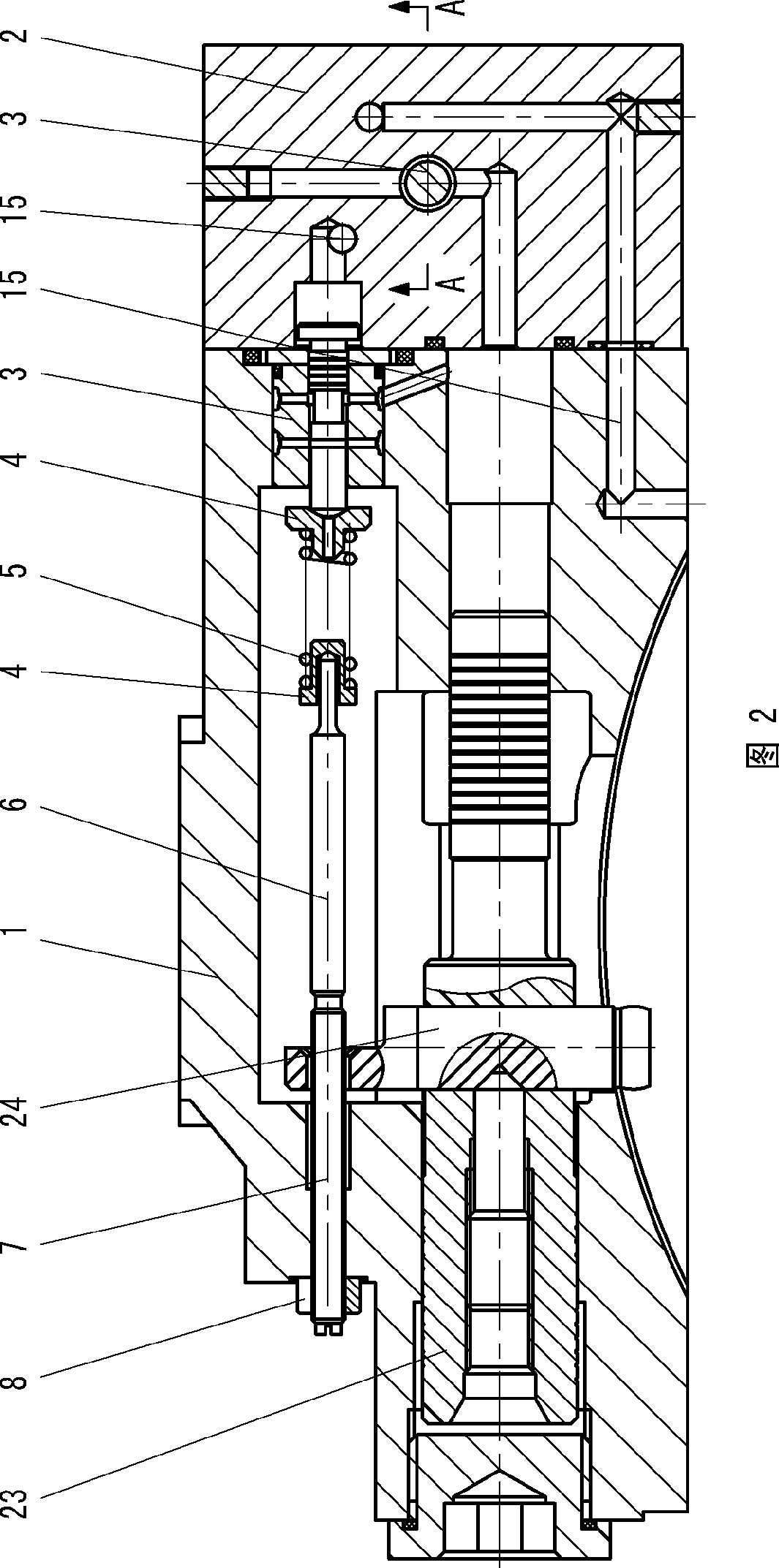

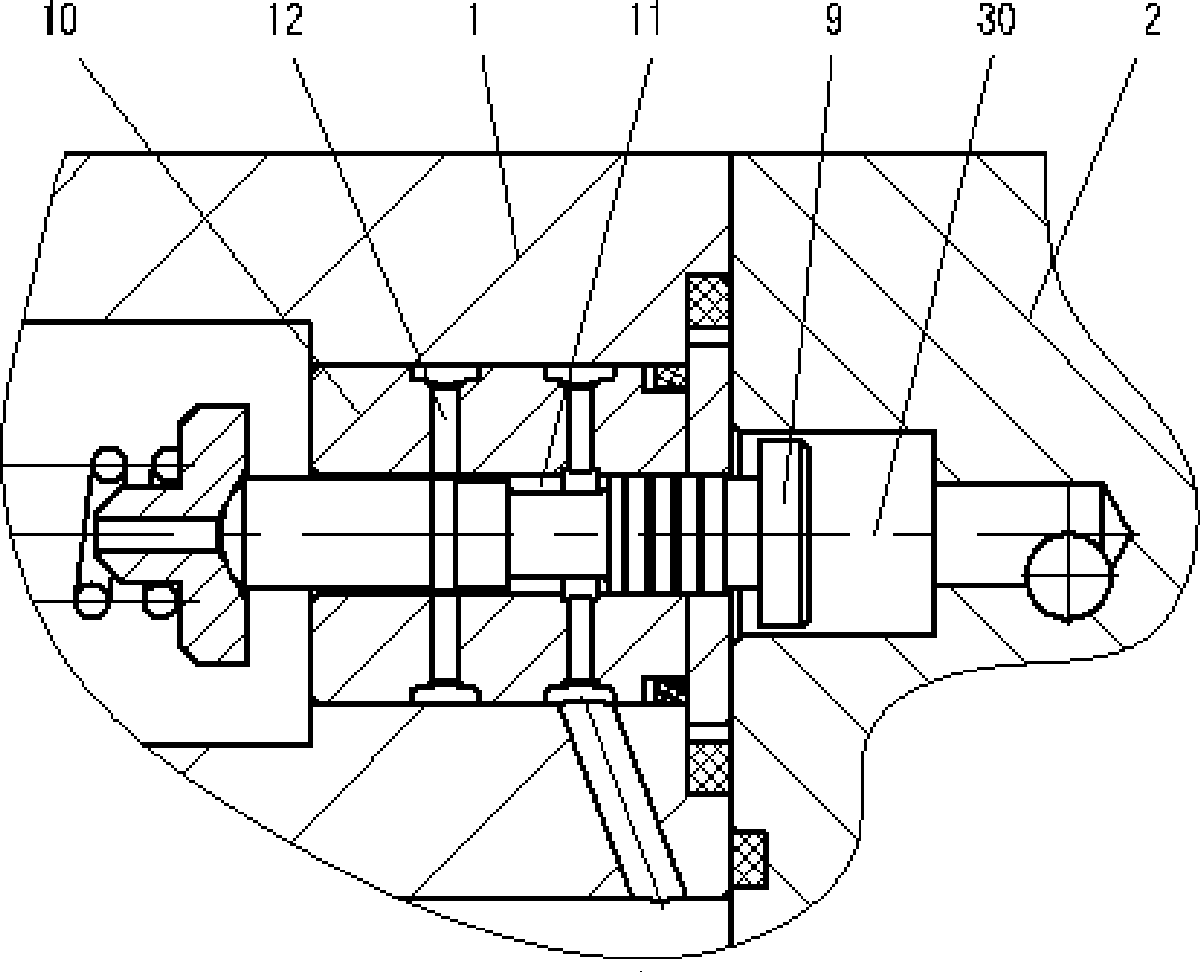

[0024] Example. Hydraulic motor speed hydraulic control method, the hydraulic principle of this method is as follows figure 1 shown. The purpose of adjusting the speed and torque of the hydraulic motor 21 is to achieve the purpose of adjusting the speed and torque of the hydraulic motor 21 by using the external control oil pressure through the speed hydraulic control valve 3 to control the oil circuit of the large chamber 20 and the small chamber 25 in the motor variable cylinder 19; When it is equal to or equal to the set value, the oil circuit of the large cavity 20 of the variable piston cylinder is cut off, and the hydraulic motor 21 is in a state of large displacement and maximum torque; when the speed of the hydraulic motor 21 is higher than the set value and not greater than the rated value, The oil circuit of the large chamber 20 is connected by the speed hydraulic control valve 3, and the displacement and torque of the hydraulic motor 21 gradually decrease; when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com