Fully-hydraulic electric fork truck

An electric forklift, full hydraulic technology, applied in the direction of lifting devices, etc., can solve the problems of electric switches, relays, fuel tank volume limitations, maintenance difficulties, etc., to improve reliability and service life, improve safety performance, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

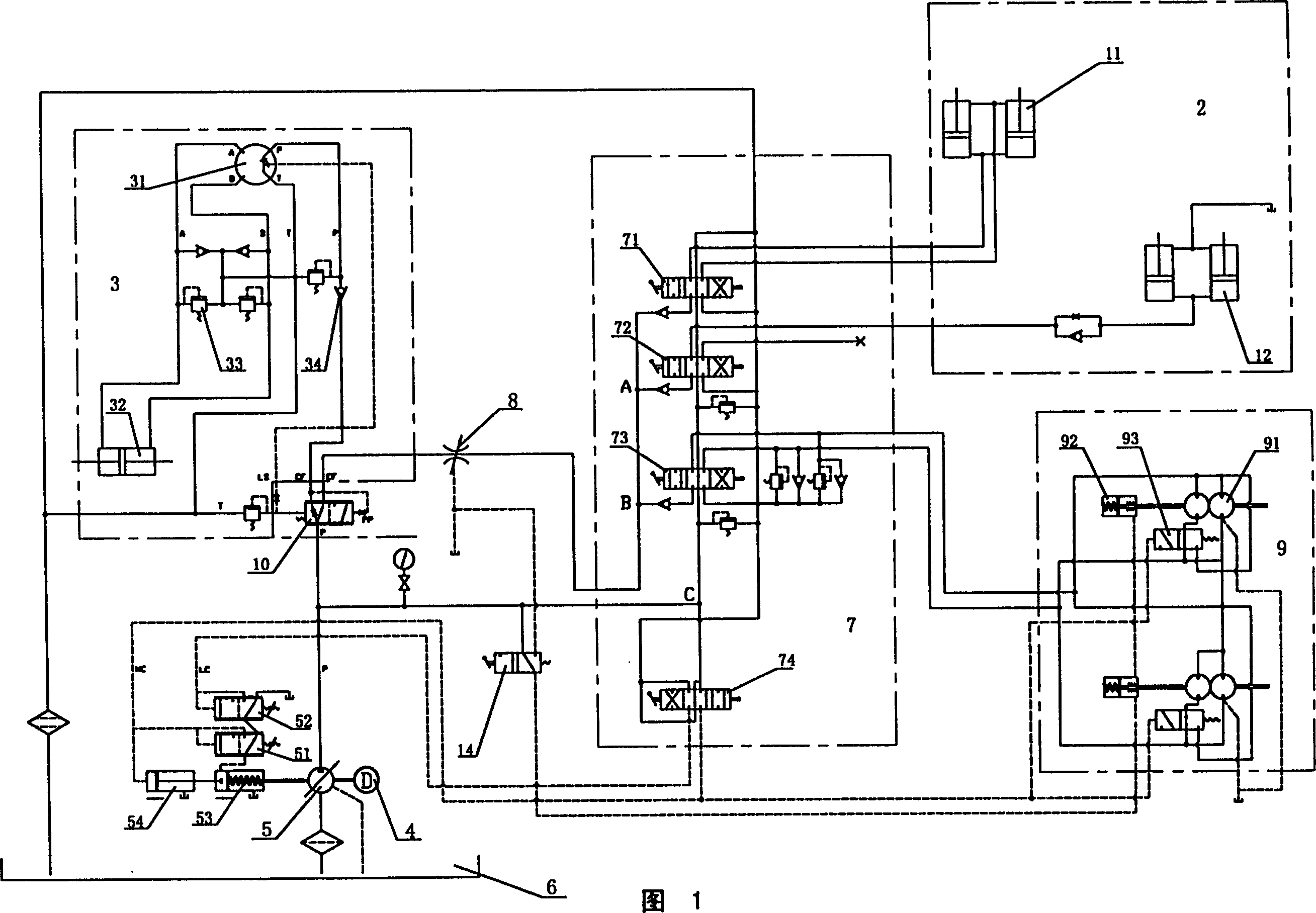

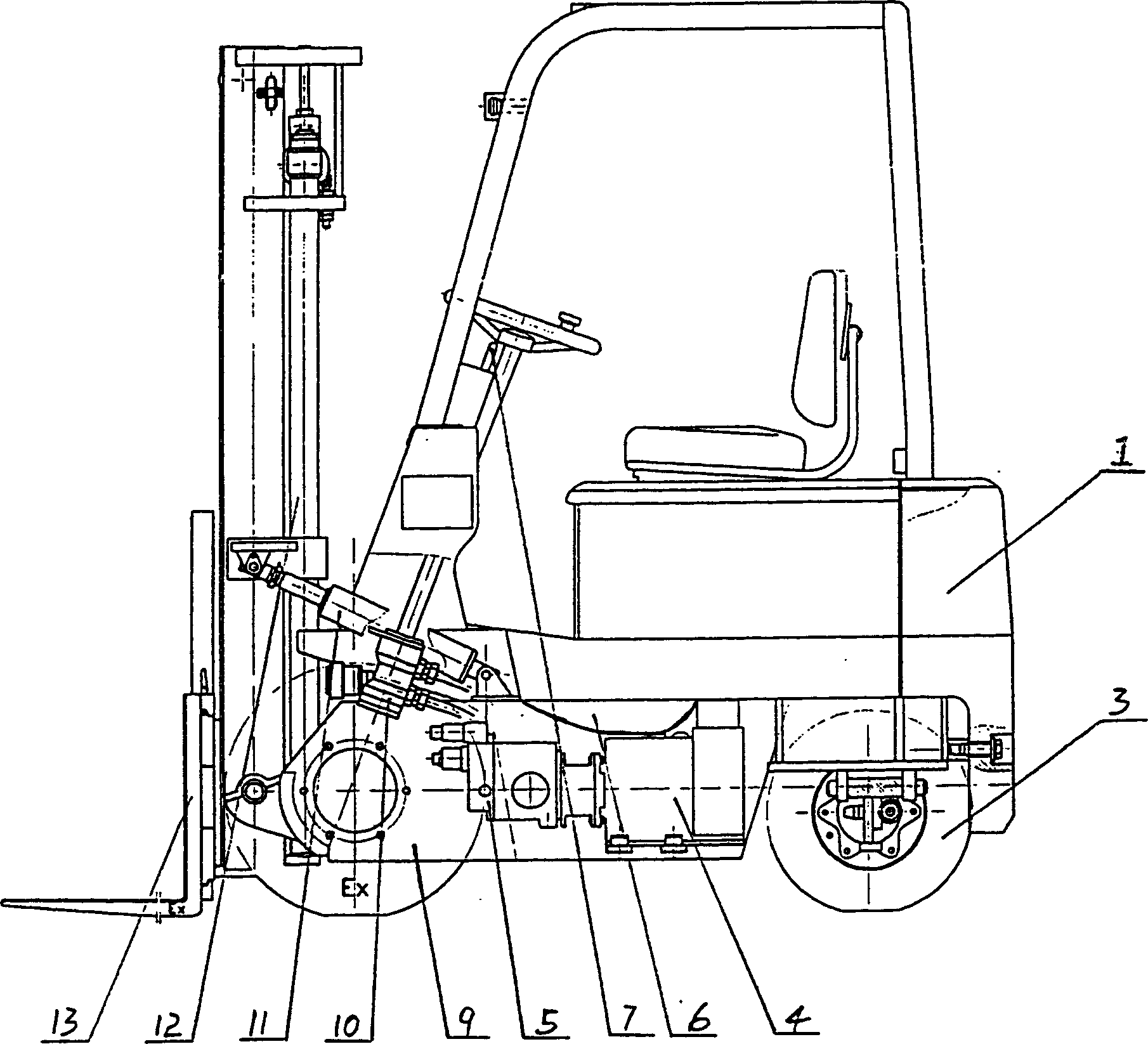

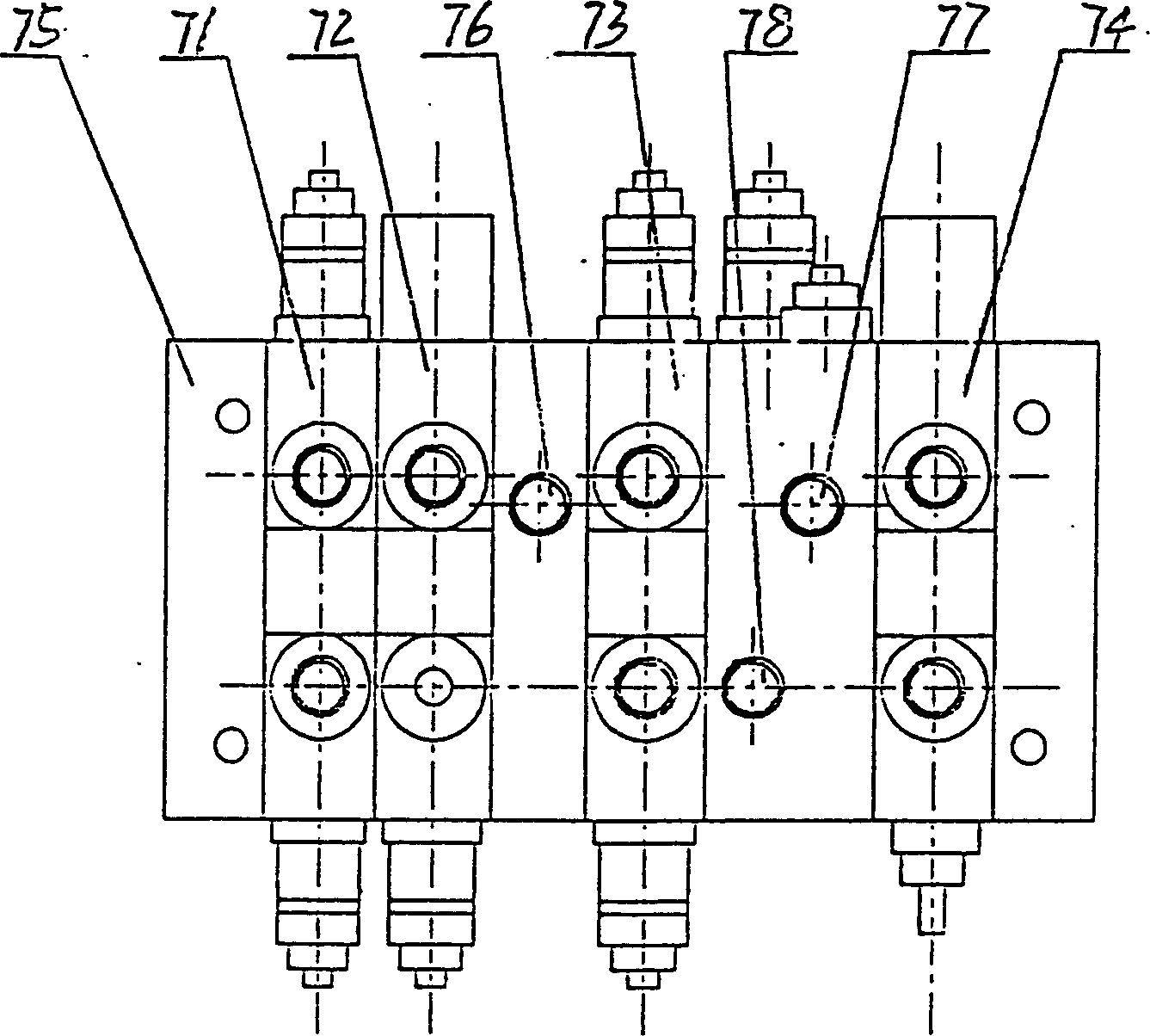

[0012] As shown in Figures 1, 2, and 3, a fully hydraulic electric forklift includes a power supply, a body 1, a double fuel tank 6, a single motor 4, a variable pump 5 connected to the single motor 4 through a coupling, a multi-way valve 7 and a fork Mast 13, steering device 3 consisting of hydraulic steering gear 31, steering cylinder 32, safety valve 33 and one-way valve 34, tilting lifting device 2 consisting of tilting cylinder 11 and lifting cylinder 12, two-speed hydraulic motor 91 1. The hydraulic brake 92 and the hydraulic speed regulating valve 93 arranged on the motor form the walking drive device 9, and the hydraulic brake 92 is controlled by a hydraulic brake valve 14. The multi-way valve 7 is composed of a tilt control valve 71, a lift control valve 72, a travel reversing valve 73, and a control valve 74. The four valves are connected as a whole by a connecting piece 75, and the four valves are all three-position six-way valves. , the multi-way valve is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com