Fan device and method for glass drying

A fan and glass technology, applied in the direction of drying gas arrangement, dryer, drying, etc., can solve the problems of no effect of the air knife, the effect of energy saving is not obvious, and the waste of energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

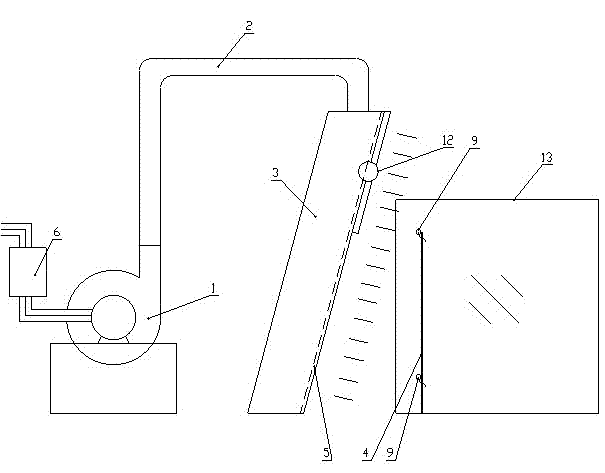

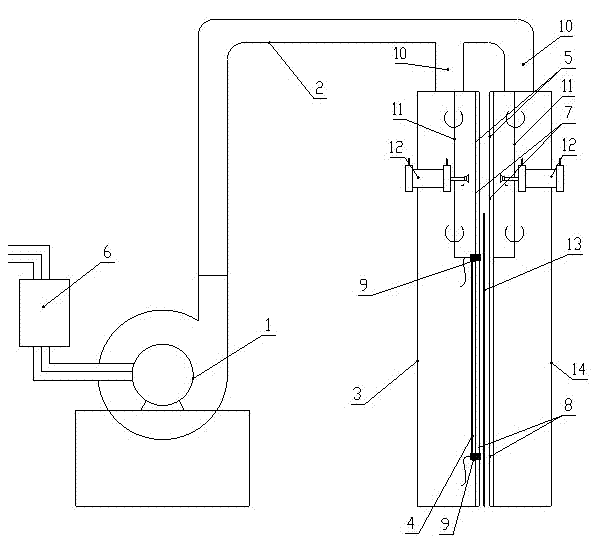

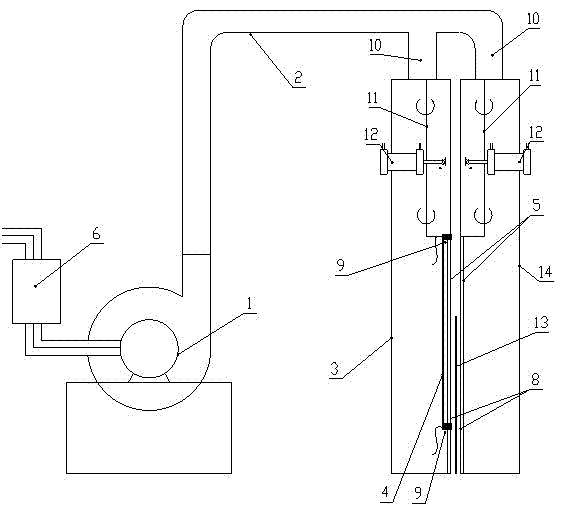

[0024] Such as figure 1 , 2 , 3, the present invention includes fan 1, air supply duct 2, left air box 3, right air box 14, air outlet 5, sensor device 4 for detecting glass height, motor frequency converter 6 and control device for adjusting air volume. The left bellows 3 and the right bellows 14 are a pair, symmetrically arranged on both sides of the glass 13

[0025] There are two air outlets 5, which are respectively located in the middle of the front side of the left air box 3 and the right air box 14. The air supply duct 2 is divided into two branch pipes 10, and the two branch pipes 10 are respectively connected to the tops of the left air box 3 and the right air box 14. .

[0026] The fan 1 is connected to the air outlet 5 through the air supply duct 2, the fan 1 includes a fan motor, and the fan motor is connected to the motor frequency conversion speed regulator 6; The air outlet 5 is divided into an upper air outlet 7 and a lower air outlet 8 according to the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com