Vehicle hydraulic and hub motor combined braking energy recycling system

An in-wheel motor and energy recovery technology, applied in electric braking systems, brakes, braking components, etc., can solve the problems of high energy recovery efficiency, unstable braking torque, and good braking effect, and achieve simple layout, mechanical The effect of simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further illustrate the present invention below in conjunction with accompanying drawing

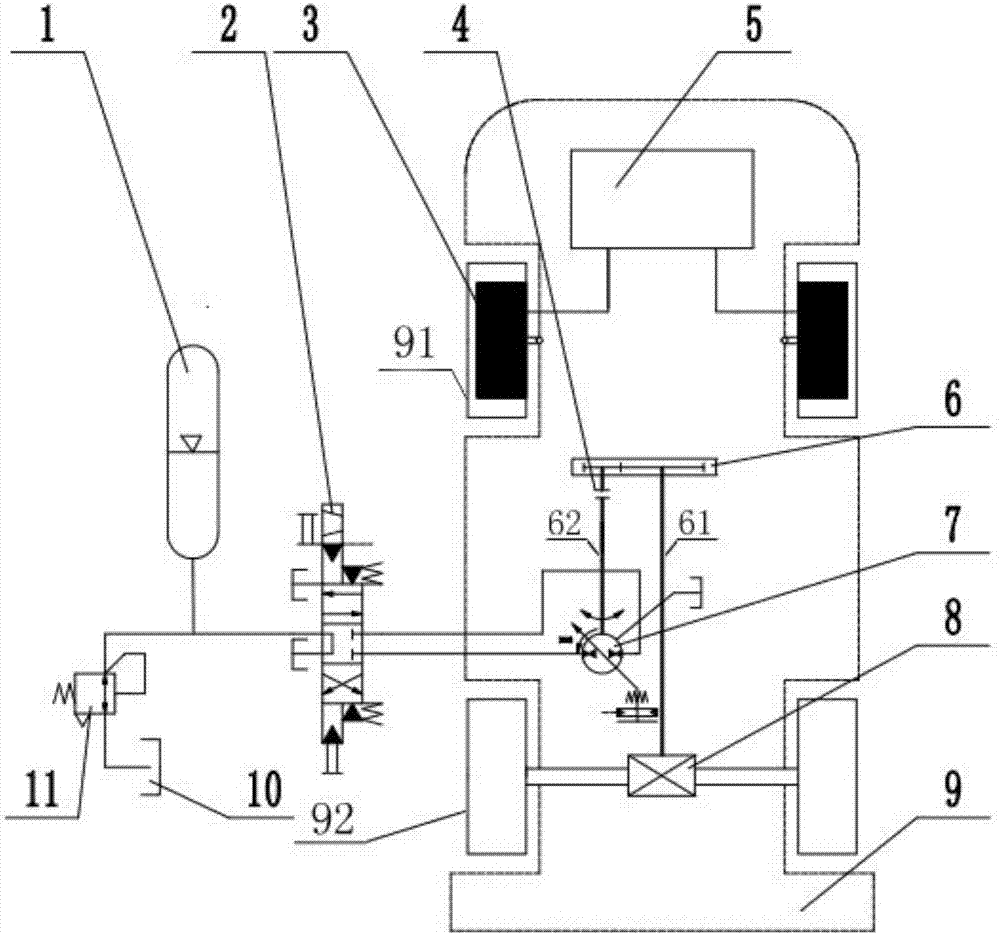

[0018] Refer to attached figure 1 :

[0019] The braking energy recovery system includes: an accumulator 1, a three-position four-way reversing valve 2, a hub motor 3 (with a traditional friction brake inside), an electromagnetic clutch 4, a battery 5, a torque coupler 6, two Secondary components pump / motor 7, transaxle 8, hydraulic oil tank 10, relief valve 11.

[0020] The battery 5 is connected to the hub motor 3 installed on the front wheel 91; the hub motor 3 is connected to the input shaft on the vehicle body 9 through the suspension; the power coupler 6 is connected to the drive axle 8 through the first transmission shaft 61 , the power coupler 6 is connected with the secondary element pump / motor 7 through the second transmission shaft 62, and the electromagnetic clutch 4 is arranged on the second transmission shaft 62; the secondary element pump / motor 7 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com