Automated drilling rig and method for moving and transporting pipe columns through automated drilling rig

A drilling rig and power technology, applied in the direction of drill pipe, drill pipe, casing, etc., can solve the problems of long use time, increased cost, and increased operation risk of the connecting root, so as to improve work efficiency, reduce operating costs, reduce The effect of the accident rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

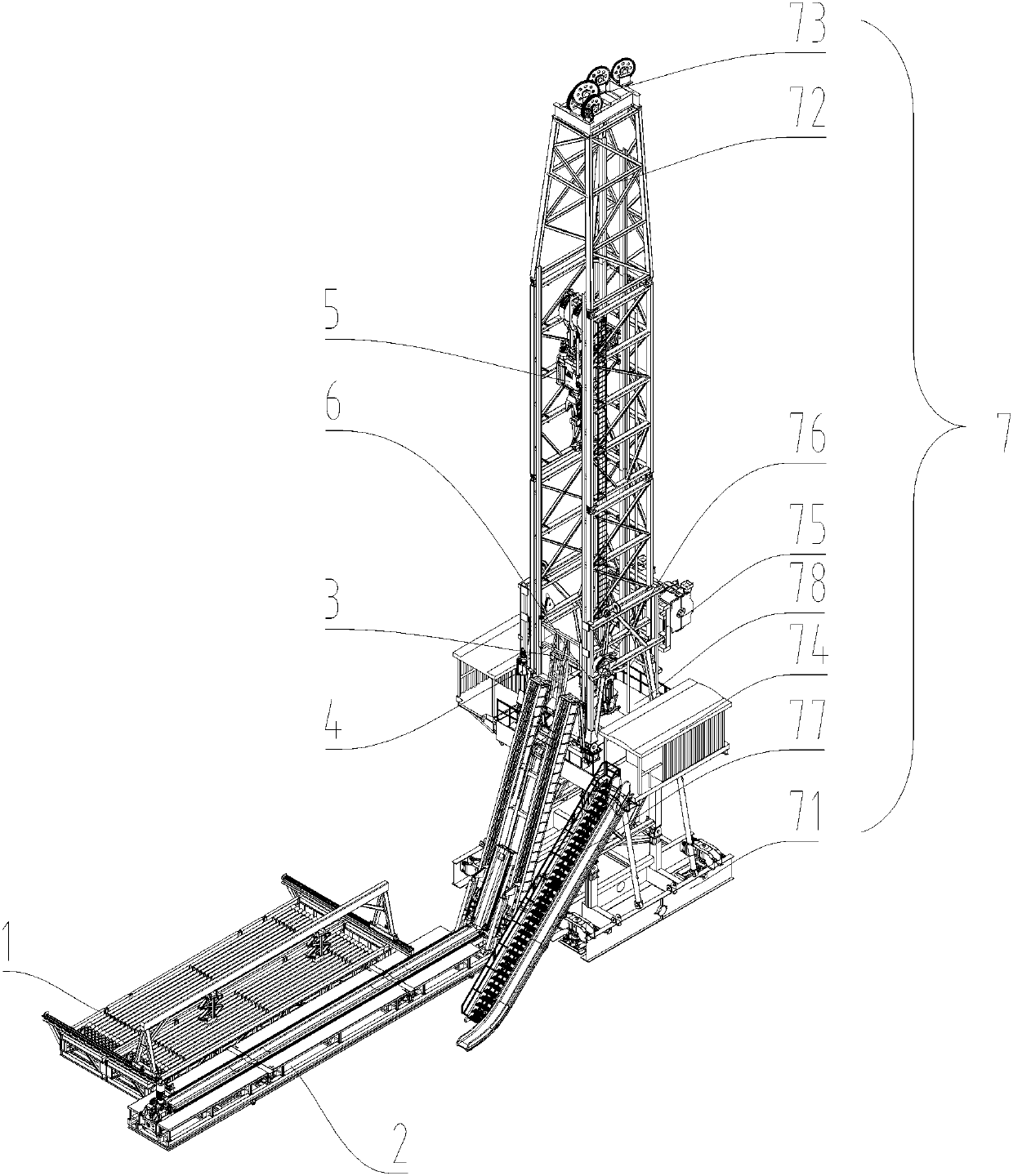

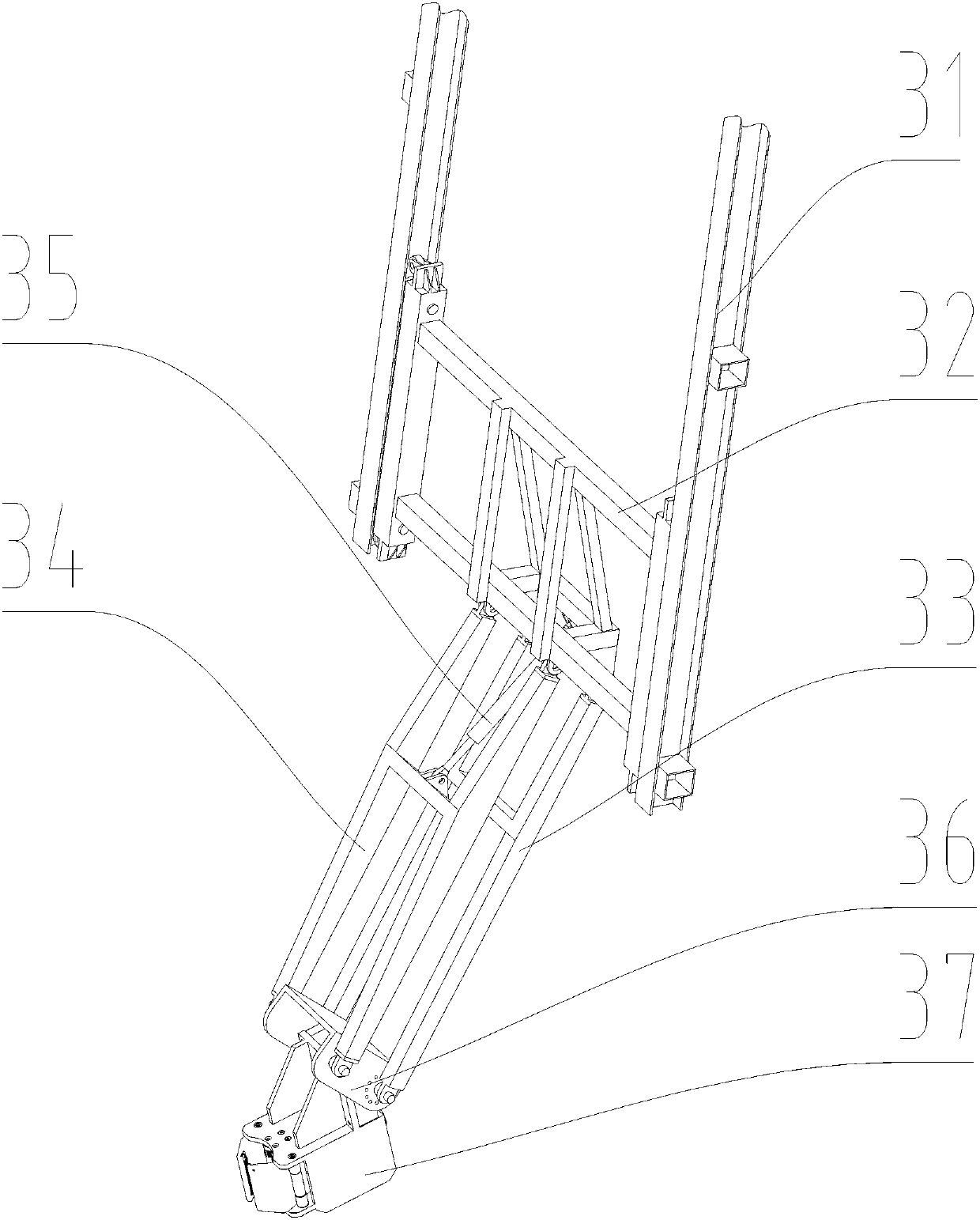

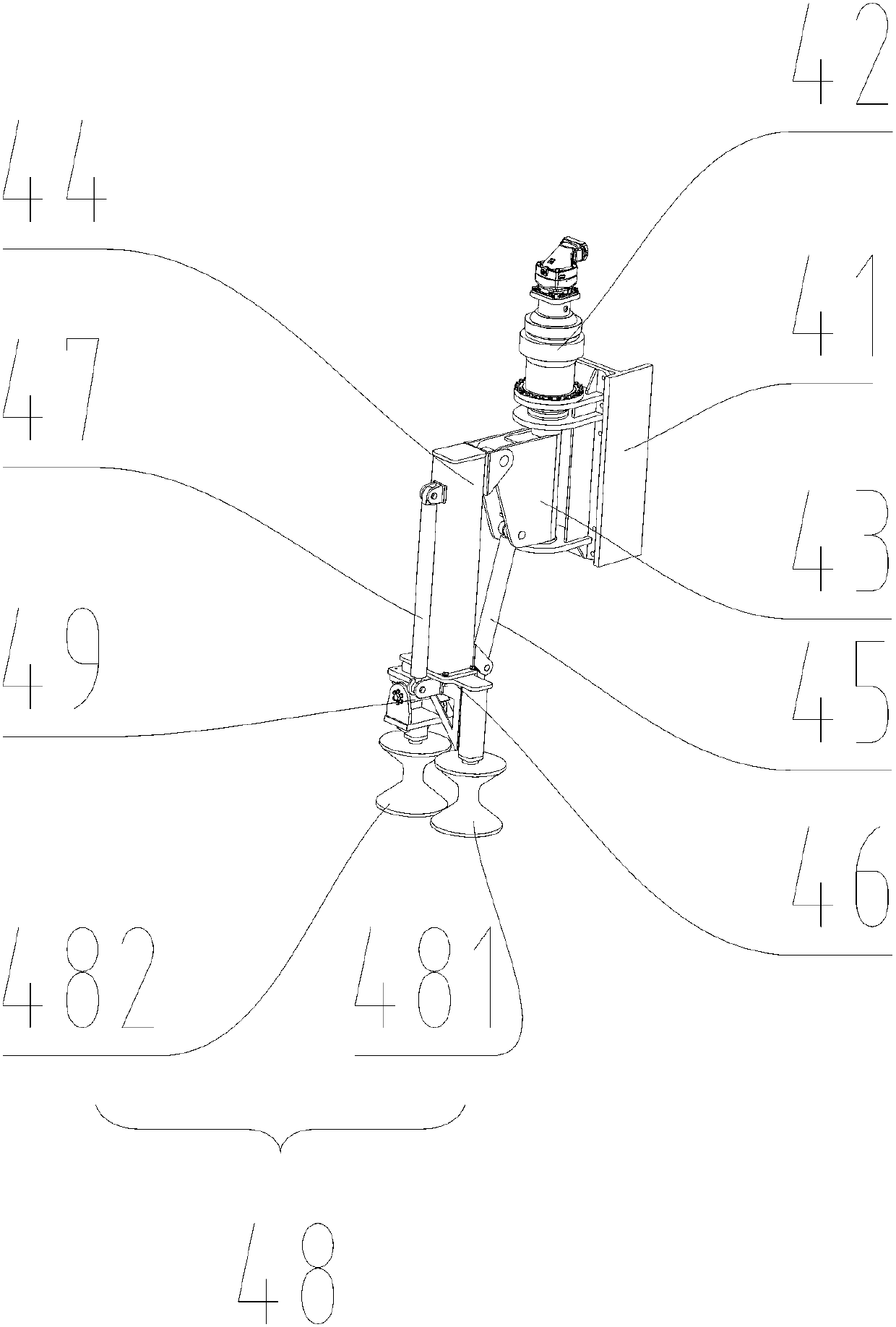

[0106] Such as figure 1 Shown, a kind of automatic drilling rig comprises the derrick assembly 7 that is fixedly connected with the foundation, the top drive assembly 5 that is movably connected with the derrick assembly 7, the iron driller 6 that is fixedly connected with the derrick assembly 7, and also includes the The power pipe box 1 that is fixedly connected, the power catwalk 2 that is fixedly connected with the foundation and the derrick assembly 7 respectively, and the double-root grasping manipulator 3 and the supporting manipulator 4 that are respectively fixedly connected with the derrick assembly 7; The derrick base 71 fixedly connected, the derrick 72 fixedly connected with the top of the derrick base 71 , the drill floor 78 fixedly connected with the derrick 72 , the driller's cabin 74 fixedly connected with the drill floor 78 , the direct drive drawworks fixedly connected with the middle and lower part of the derrick 72 75, the dead rope fixer 76 fixedly connec...

Embodiment 2

[0119] Such as Figure 8 , 10 As shown in -15, a method of using the aforementioned automatic drilling rig to move pipe strings, it includes the following steps:

[0120] Step 1. The driving device 15 drives the gantry crane 13 to drive the telescopic pipe grasping tongs 14 to the position of the double poles, and the telescopic pipe grasping tongs 14 grab the double poles and raise them to a certain height;

[0121] Step 2, the driving device 15 drives the gantry crane 13 to drive the telescopic pipe gripper 14 to the edge of the power catwalk 2, the telescopic pipe gripper 14 descends and places the two on the power catwalk 2, and the gantry crane 13 resets;

[0122] Step 3, the power catwalk 2 drives the double root 78 above the drill floor;

[0123] Step 4, grabbing the double root manipulator 3 slides down along the derrick 72, and the gripper 37 clamps one end of the double root;

[0124] Step 5, the top drive assembly 5 rises to get out of the wellhead position;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com