A floor rail type highly integrated intelligent iron driller

A highly integrated, iron driller technology, applied in drill pipes, drill pipes, drilling equipment, etc., can solve the problems of easy fatigue damage of springs, poor integration of iron drillers, low degree of automation, etc., to improve work efficiency and increase The effect of equipment life and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

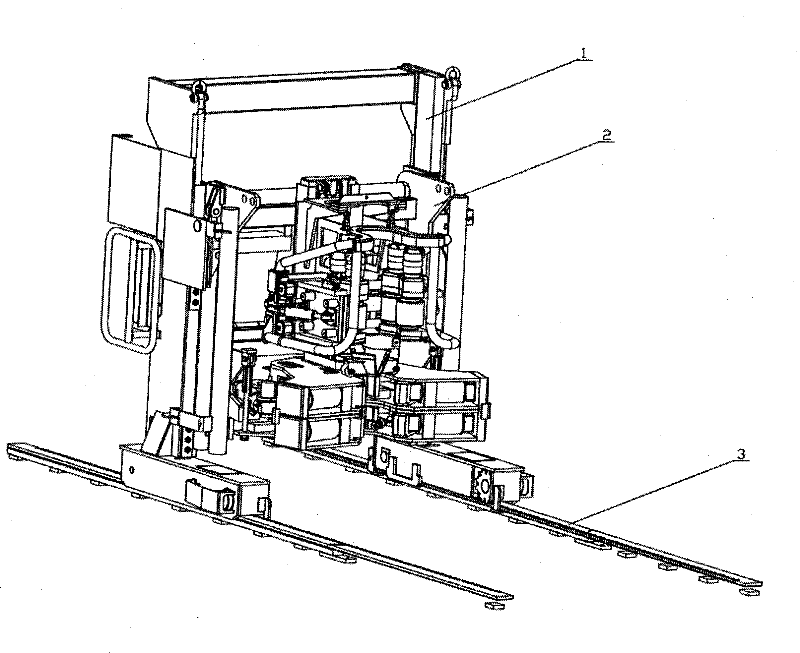

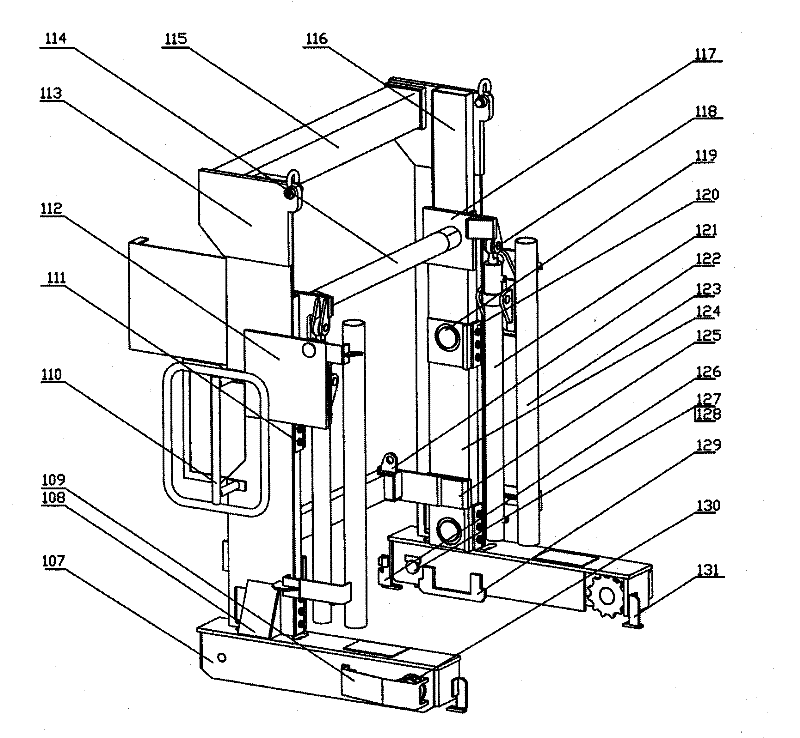

[0022] Example 1: Combining Figure 1-Figure 12, the present invention is a floor track type highly integrated intelligent iron driller, which is composed of a lift car (1), a clamp head frame (2), and a guide rail (3), and the lift car (1) is on the guide rail (3) Move, the upper part of the clamp head frame (2) is articulated on the lift truck (1), and the lower part of the clamp head frame (2) is connected with the lift truck (1) through a shackle (4), and the lift truck (1) is composed of left and right The two side frames are composed of crossbeams, and the left and right side frames are respectively installed on two guide rails (3). The lift car (1) drives the transmission gear (102) to rotate through the lift car hydraulic motor (130) to realize the movement on the guide rail (3). Move up, the front positioning plate (131) welded on the front and rear plates of the foot box, the rear positioning plate (126) and the baffle plate (129) connected by bolts on the inner plat...

Embodiment 2

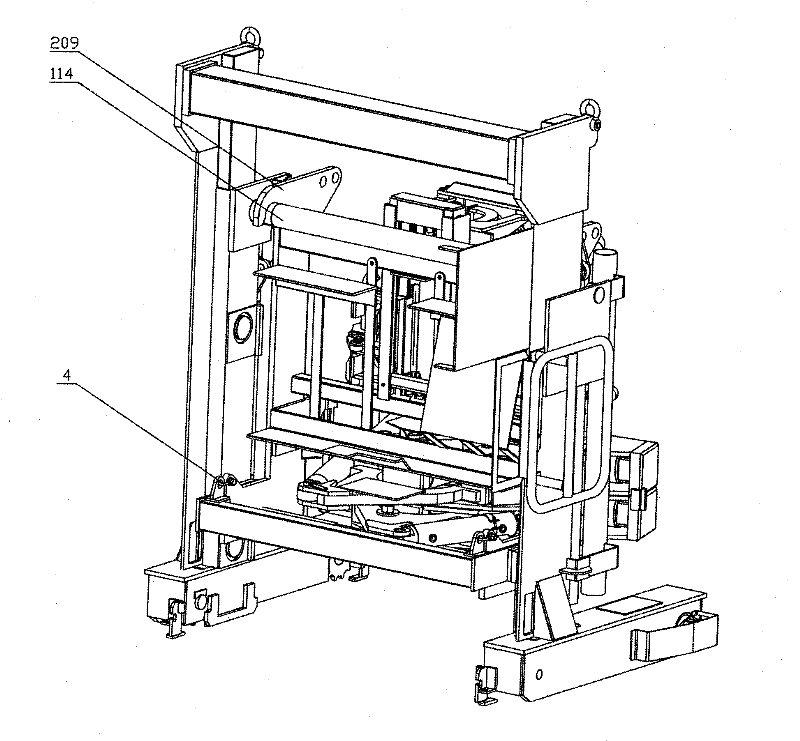

[0027] Example 2: Combining Figure 2-Figure 6 , the lifting vehicle (1) of the present invention moves on the guide rail (3), and the pincer head frame (2) is articulated on the slide rail column beam of the lifting vehicle (1) through the upper hook plate of the upper back frame splint (209) (114), and the lower beam (125) of the slide rail (125) is connected with the lower hole of the back frame splint (209) by a shackle (4).

[0028] figure 2 Be lift car (1): lift car (1) is made up of left and right side frame and beam. The left and right side frames are installed on two guide rails (3) respectively, and the drive gear (102) at the bottom of the left and right side frames is engaged with the gear rack on the inside of the guide rail (3) to realize the advancement and retreat of the lift car (1). The transmission gear (102) is connected to the lift car hydraulic motor (130) transmission on the foot box outer plate (107) at the bottom of the left and right sides by bolts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com