Pipe gripping ram

a technology of gripping rams and pipes, which is applied in the direction of drilling accessories, fluid removal, borehole/well accessories, etc., can solve the problem of taking several hundred foot-pounds of torque to break the connection between sections of pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

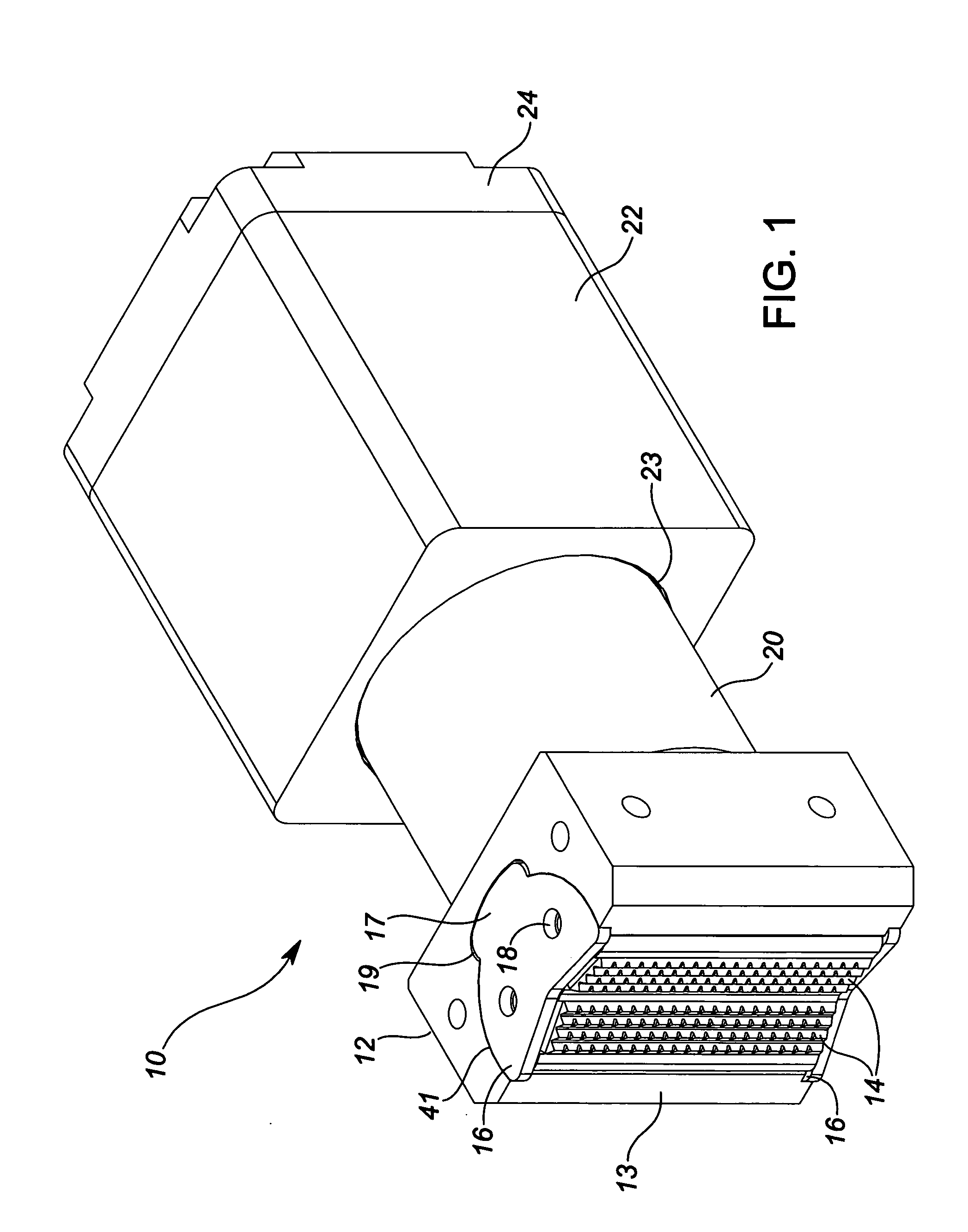

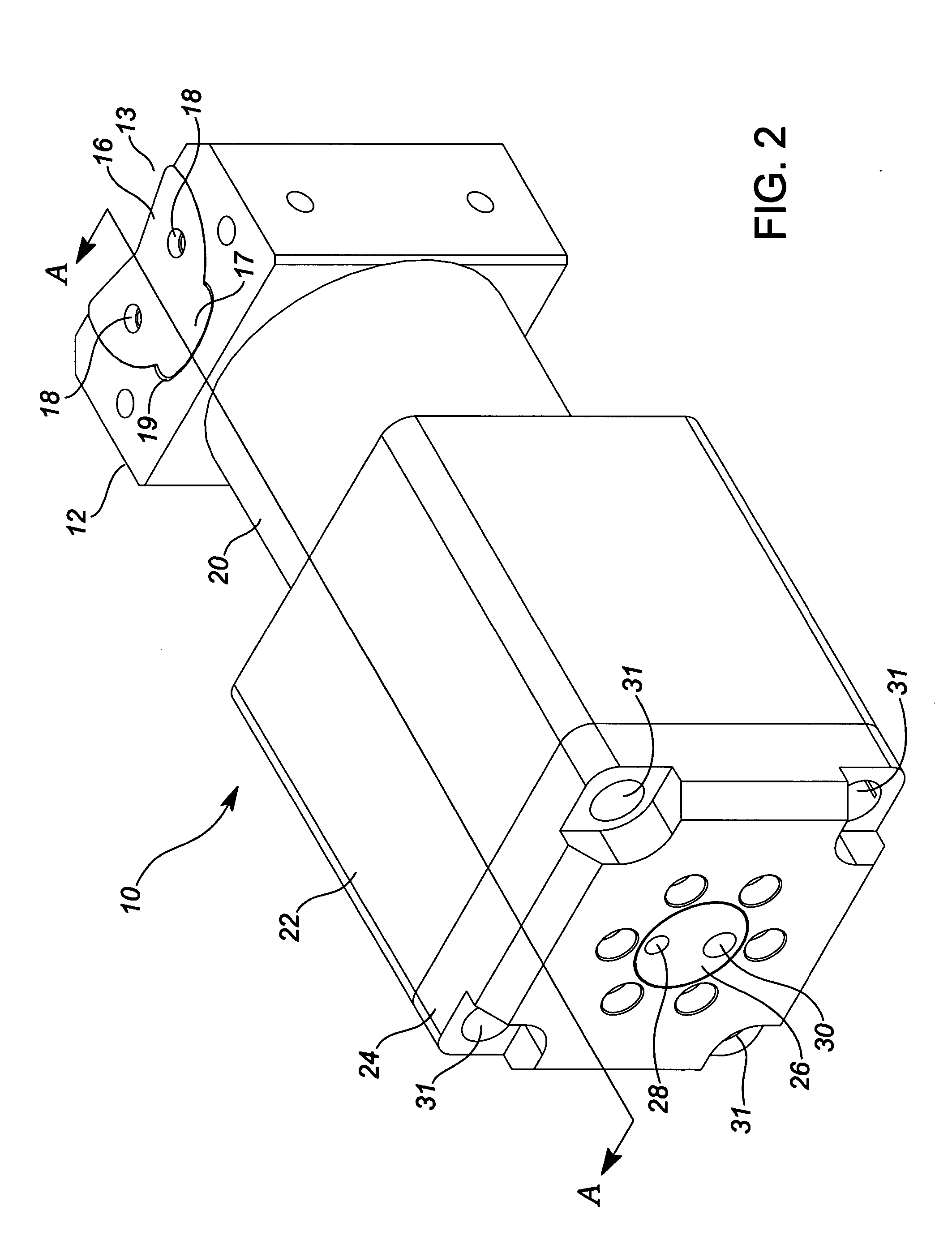

[0019] Referring to FIGS. 1 and 2, a representative embodiment of the present invention is shown. Ram 10 comprises a cylinder block 22, end cap 24, annular piston 20 and tong shoe 12. End cap 24 is fastened to cylinder block 22 by cap screws passing through bolt holes 31. Annular piston 20 slides in and out of bore 23 and cylinder block 22. Tong shoe 12 has a circular opening 41 to receive tong die 13. Tong die retainers 16 are fastened to the top and bottom of tong die 13 to keep it in place within shoe 12. Tong die 13 comprises a pair of die faces 14. Die faces 14 form a shell v-shaped groove for receiving a section of pipe to grip.

[0020] Tong shoe 12 further comprises grooves 19 to receive retainer ear 17 of retainers 16. Groove 19 is slightly wider than ear 17 so as to allow tong die 13 to move laterally side-to-side within opening 41. A combination of shallow v-shaped groove faces 14 and the side-to-side movement of tong die 13 allows tong die 13 to self-center on a section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com