Optical sub-module detecting machine and detecting method

A technology of optical sub-module and inspection machine, which is applied in the direction of optical instrument testing, measuring device, machine/structural component testing, etc. It can solve the quality error of optical sub-module finished product inspection, the quality of finished product cannot be accurately grasped, and the efficiency of semi-automatic inspection is low, etc. problems, to achieve the effect of reducing testing costs, shortening the waiting time for testing, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to understand the purpose, features and advantages of the present invention more clearly, the following describes the embodiments of the present invention in detail by taking the light emitting sub-module as an example and in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following embodiments.

[0067] In an embodiment of the present invention, the aforementioned mechanism components can be implemented by the following structure:

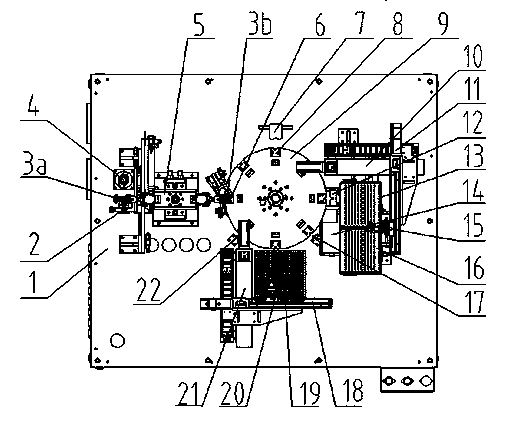

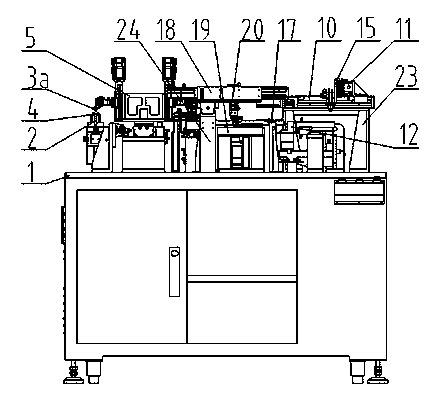

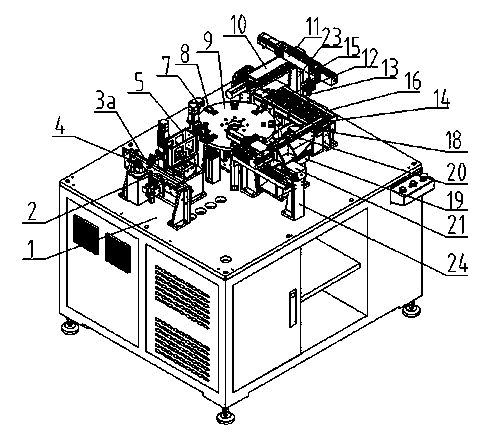

[0068] Such as figure 1 , 5 , 10, the fiber end face detection cleaning and fiber insertion coupling mechanism adopts the fiber head cleaning mechanism 2, the fiber head clamping mechanism 3a (3b), the fiber head end face cleanliness detection lens 4, the rotating frame 5, the guide clamp finger 6, The electrical signal transmission probe 25 is specifically implemented.

[0069] Such as figure 1 , 2 , 3, 4, and 6, the feeding mechanism components adopt X-direction linear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com