Full-automatic modular multi-sample intelligent processing system

An intelligent processing system and modular technology, applied in the preparation of test samples, analysis materials, instruments, etc., can solve the problems of time-consuming, labor-intensive efficiency, etc., and achieve the effect of simplifying the operation process and increasing the number of samples processed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

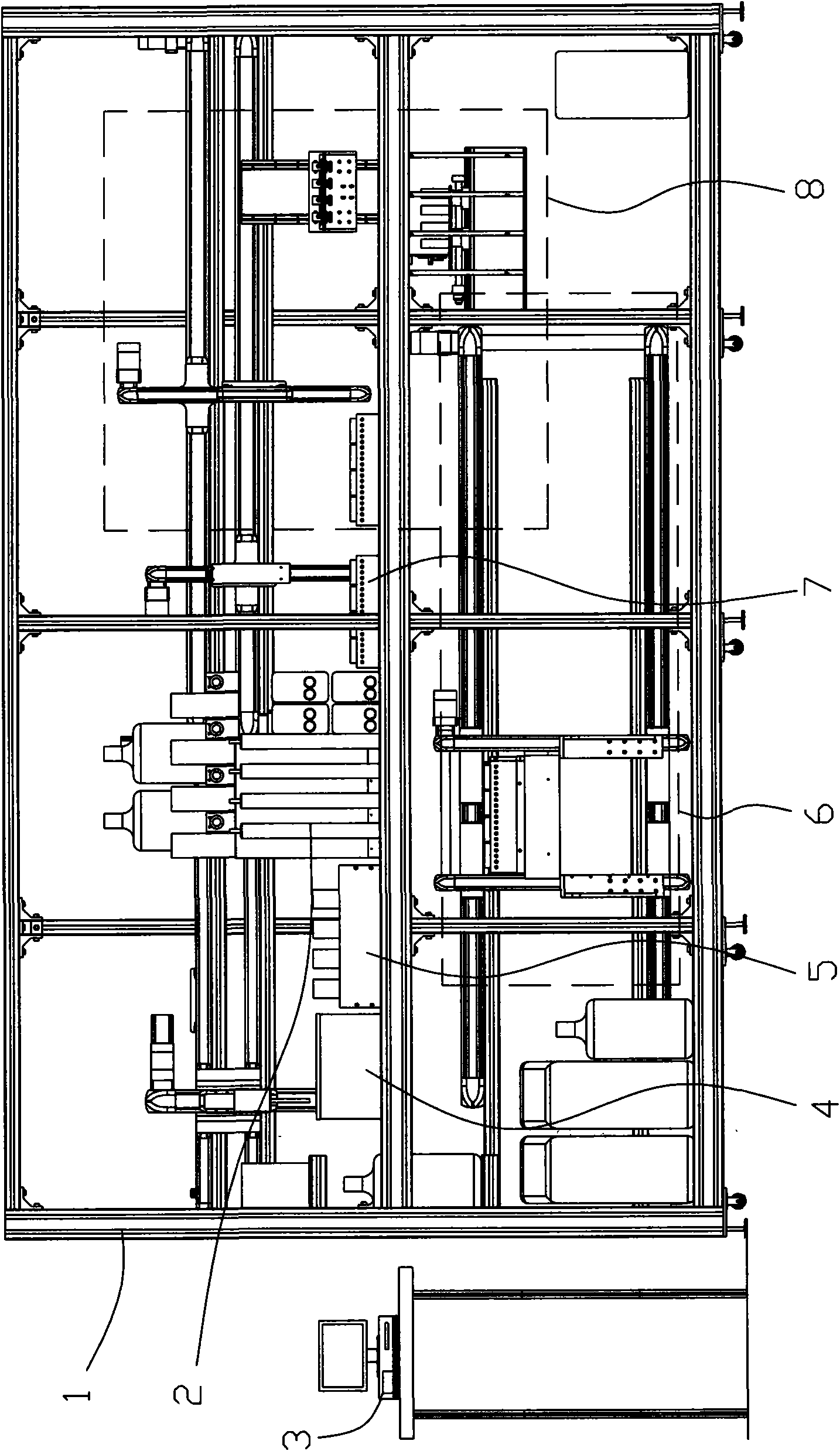

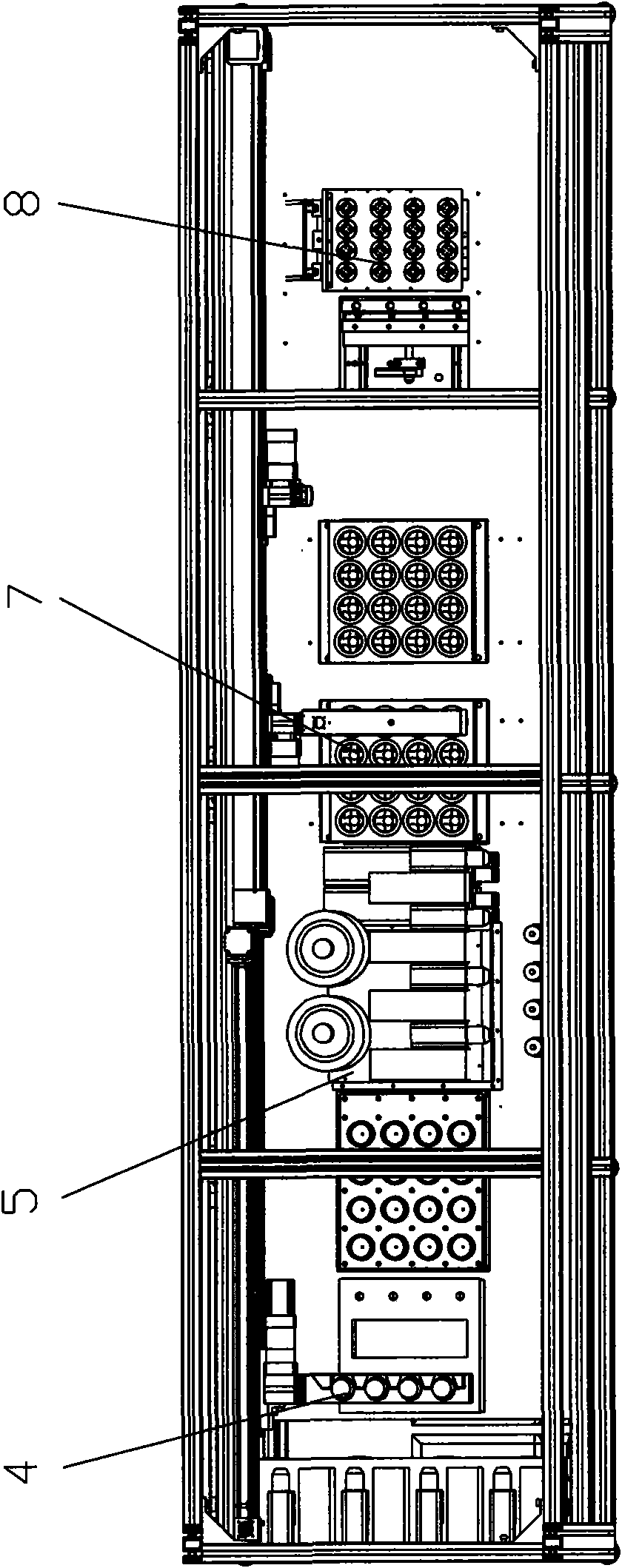

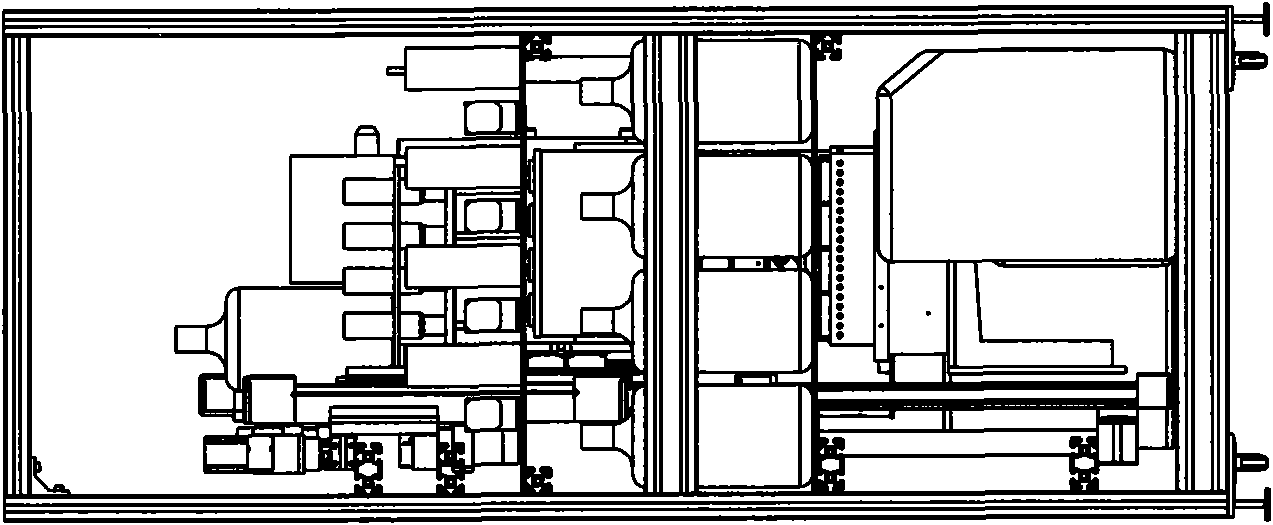

[0016] like Figure 1 to Figure 3 As shown, a fully automatic modular multi-sample intelligent processing system of the present invention includes a liquid adding and homogenizing module 4 for adding liquid and homogenizing the sample, and an automatic vacuum filter for filtering the sample solution. Module 5, automatic nitrogen blowing concentration module 2 for concentration treatment of sample solution, automatic gel permeation purification module 7 for purification treatment of sample solution, automatic solid phase extraction module for solid phase extraction treatment of samples 8. An automatic transmission and heating module for transmitting sample test tubes and heating them. 6. Operation control module 3. According to the processing needs of different samples to be processed, the corresponding processing modules and experimental condition programs are selected by editing the operation control module 3. And operating procedures, to carry out the corresponding automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com