Automatic sand blasting and spraying equipment

A technology for sand blasting, derusting and spraying equipment, which is applied in the direction of metal processing equipment, coatings, spraying devices, etc., can solve problems affecting work efficiency and construction safety, difficulty in ensuring construction safety, and affecting project quality, etc., to achieve Increase construction safety, reduce unnecessary damage, and improve project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

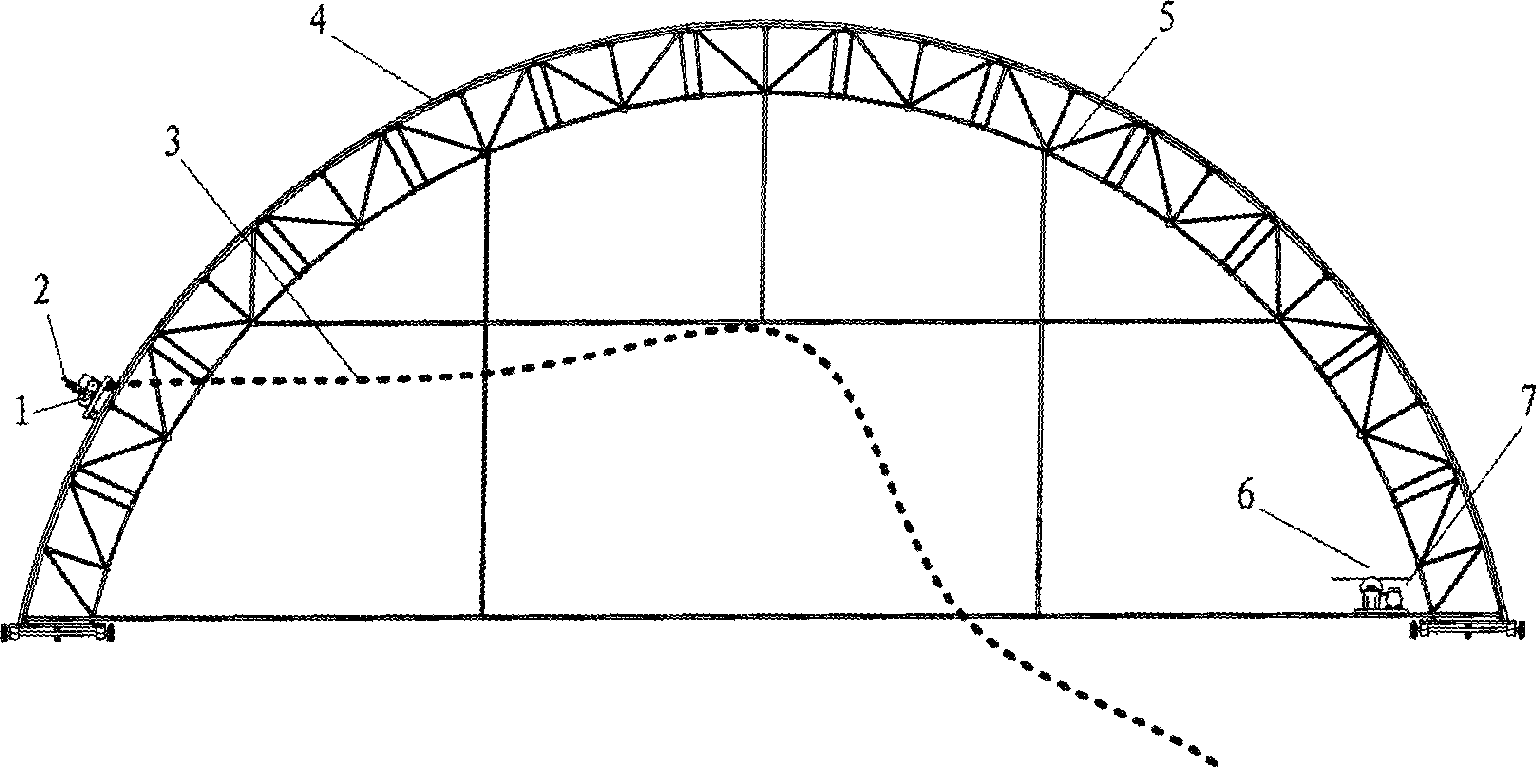

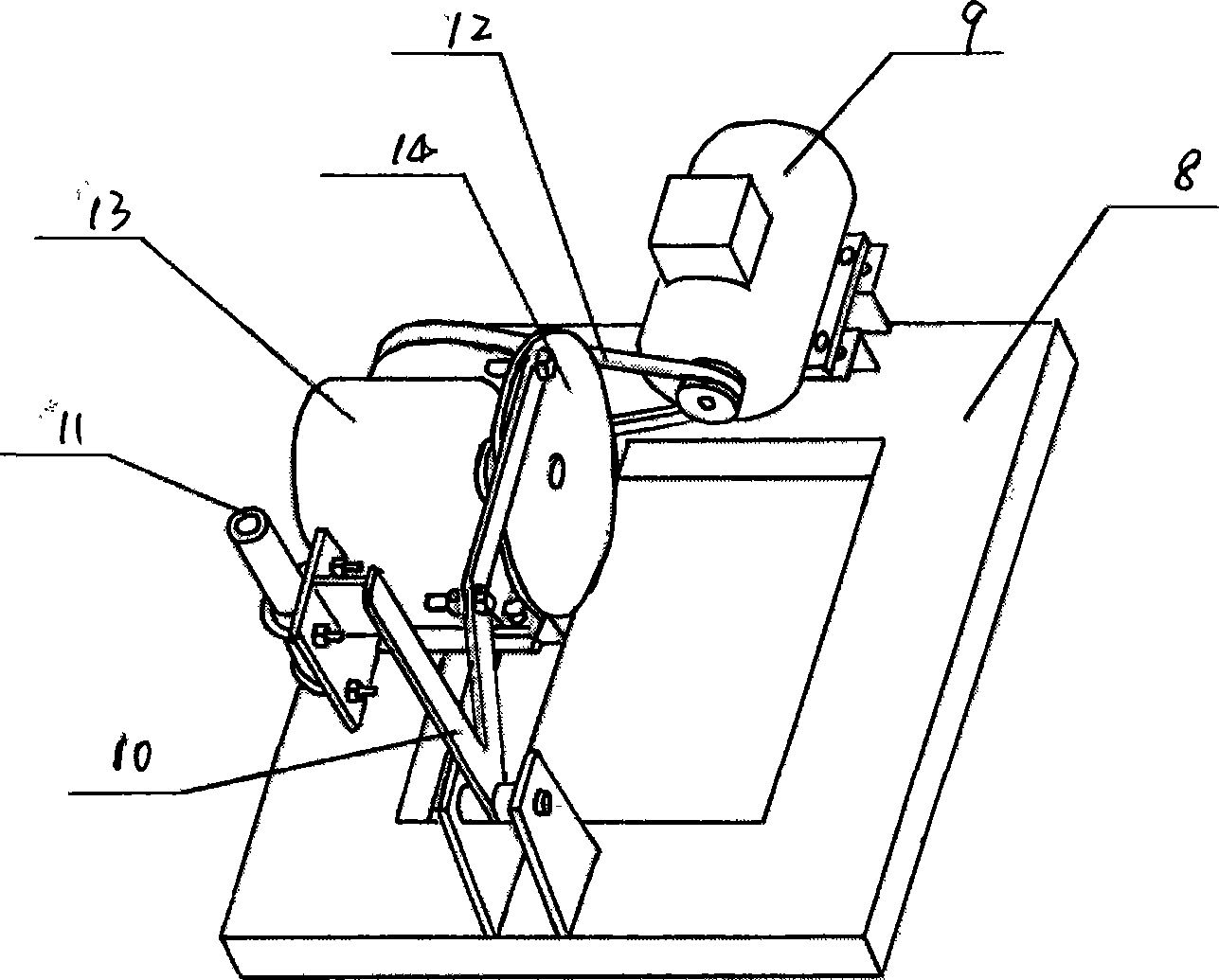

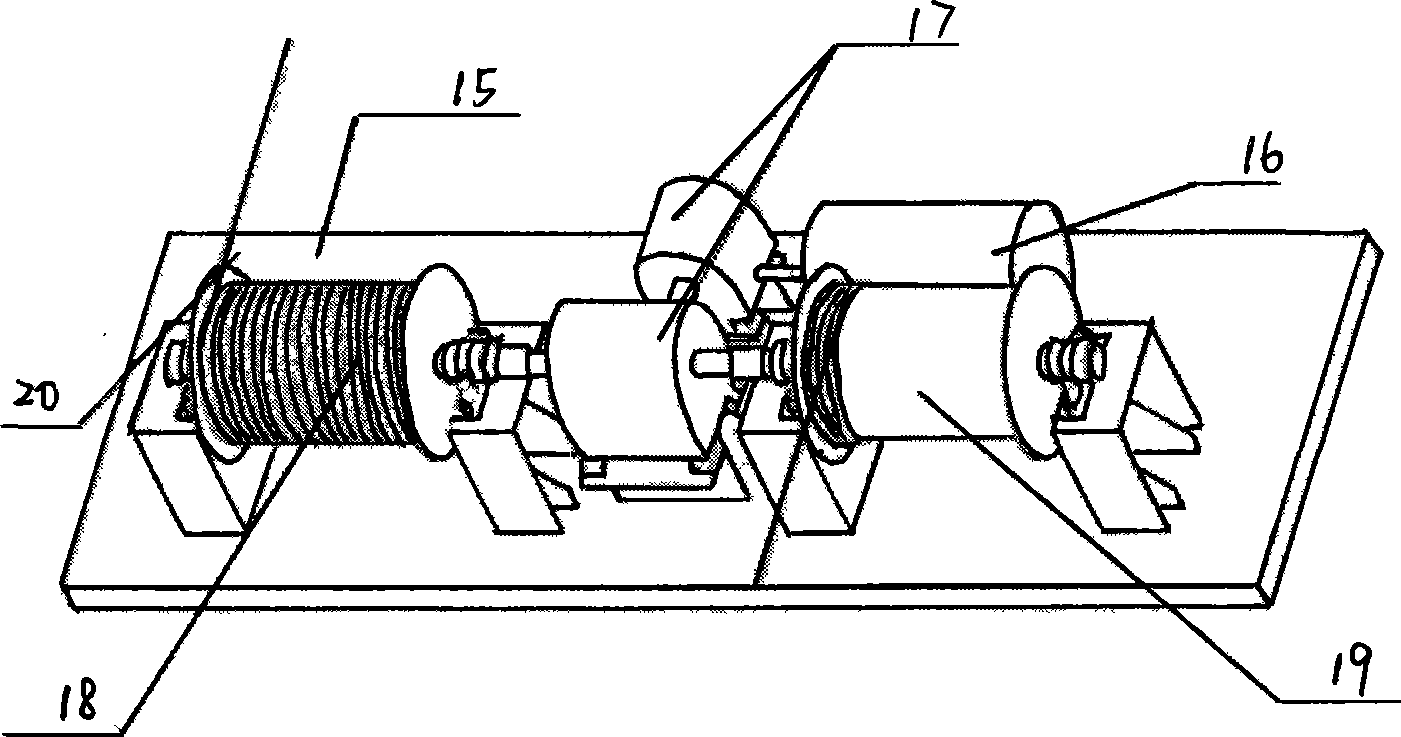

[0021] The present invention is an automatic sand blasting and rust removal and spraying equipment, and its overall structure is as follows: figure 1 As shown, it includes a mobile support with a moving mechanism 2 and a support track 4, a spray car 1 connected to a delivery pipe 3, a driving device 6, and a control device 7; wherein the mobile support includes an arched truss 5 and a truss arranged at its bottom The moving mechanism 2, the supporting track 4 is set above the arched truss 5, the control device 6 and the driving device 7 are placed on the moving bracket, and drives the spraying vehicle 1 to run back and forth on the supporting track 4; the structure of the spraying vehicle 1 is as follows: figure 2 As shown, it consists of an underframe 8, a spraying motor 9, a transmission mechanism, a crank rocker mechanism 10, and a spray gun holder 11 for installing a sandblasting gun or a paint nozzle. The spraying motor 9 is fixed on the underframe 8 and drives One end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com