Microscope slice automatic feeding device

A feeding device and automatic feeding technology, applied in microscopes, supply workbenches, transportation and packaging, etc., can solve the problems of not being able to meet the needs of large-scale automatic scanning inspections, and achieve the effect of realizing full automation and improving inspection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

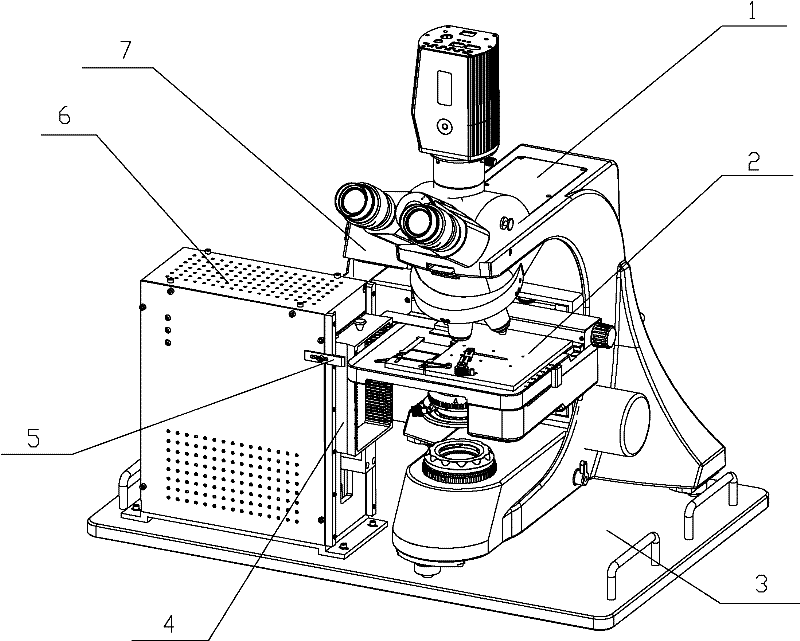

[0041] Examples, see Picture 1-1 As shown, a microscope section automatic feeding device of the present invention includes a bottom plate 3, a section feeding device 6 (including a hook dial 5), is installed on the stage of the microscope 1 and can correspond to the section feeding device 6 The clamping device 2 and the barcode scanner 7 that match the work; the slice feeding device 6 and the microscope 1 equipped with the clamping device 2 are respectively installed at the corresponding positions of the base plate 3 so that the slice feeding device 6 and the clamping device 2 can cooperate with each other .

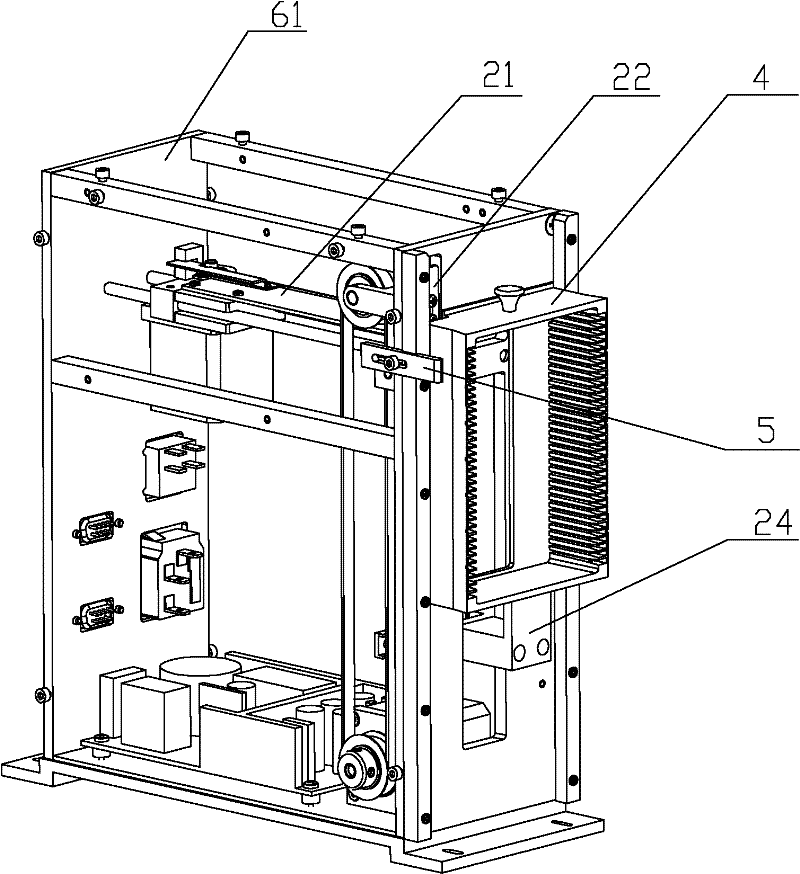

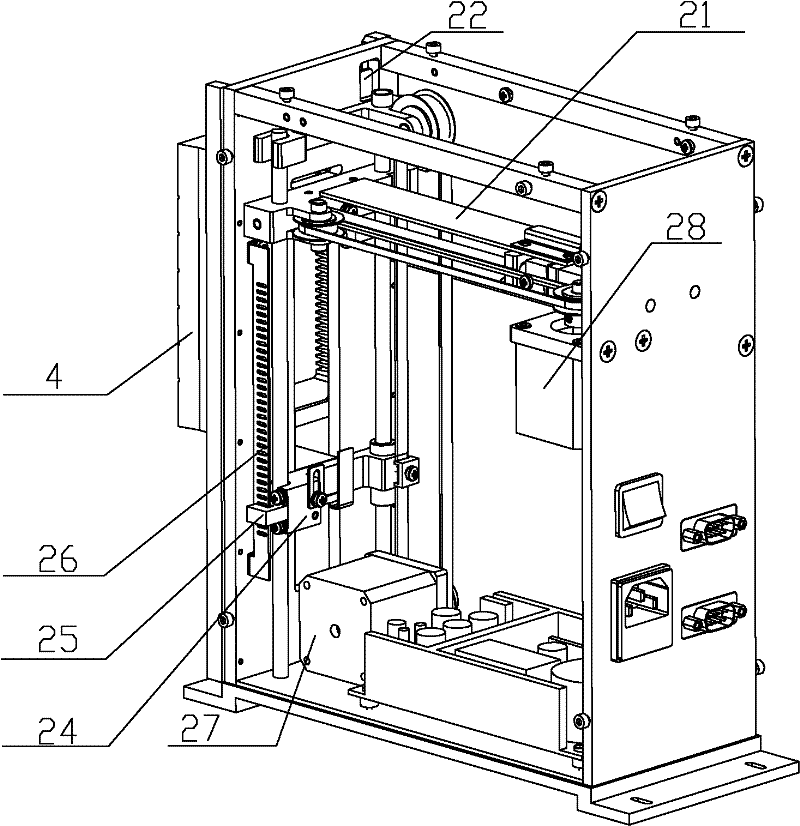

[0042] The structure of slice feeding device 6 please refer to Figure 2-1A , Figure 2-1B As shown, the slice feeding device 6 includes: a slice feeding device main body 61, a slice box 4, a bracket 24 of the slice box 4, a sheet feeding push plate 21, a hook dial 5, and is used to detect whether the slice is in the slice box 4. The slice sensing device 22 in the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com