Optical fiber terminating device

An end-to-end and optical fiber technology, which is applied in the direction of grinding devices, grinding machine tools, working carriers, etc., can solve the problems of affecting the processing accuracy of the workpiece to be polished, the increase of the cost of the grinding process, and the scratches of the workpiece to be polished.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

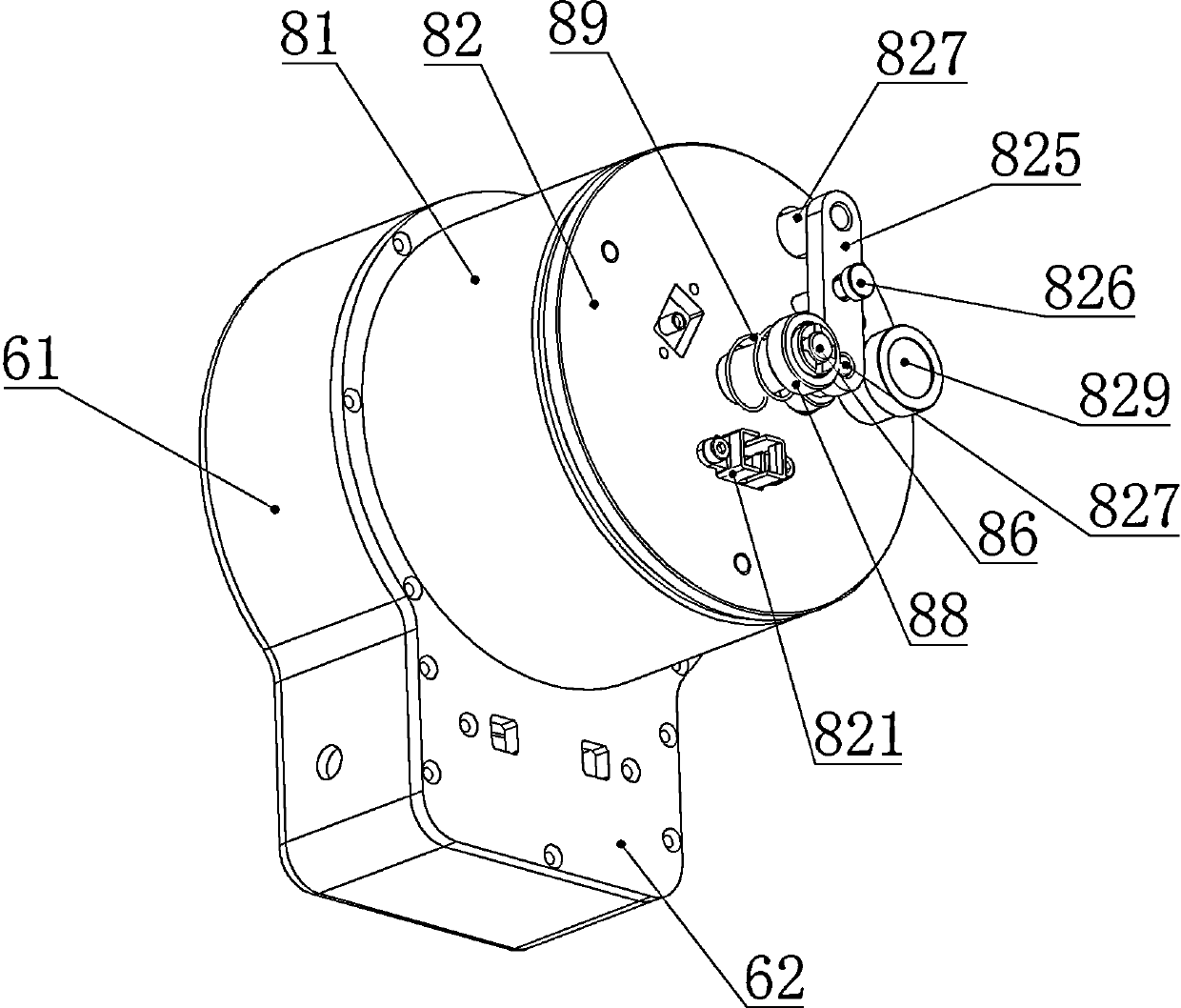

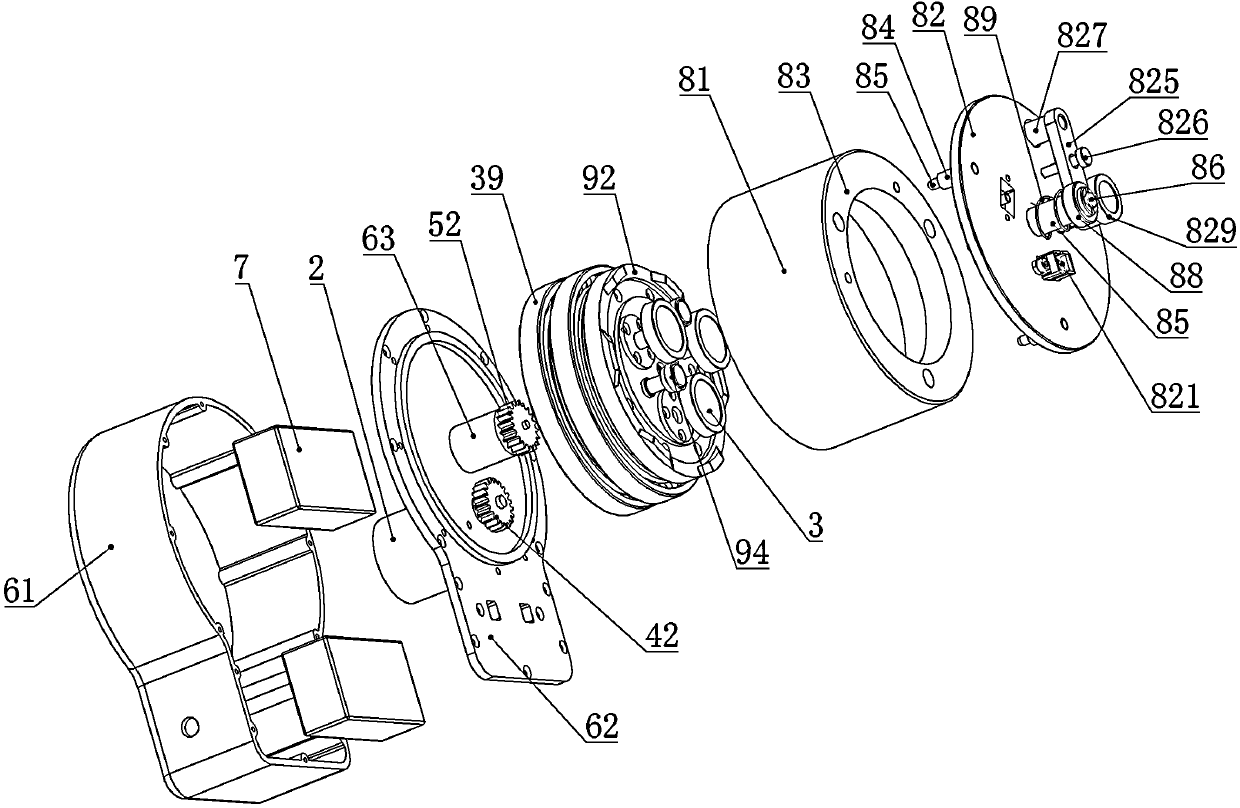

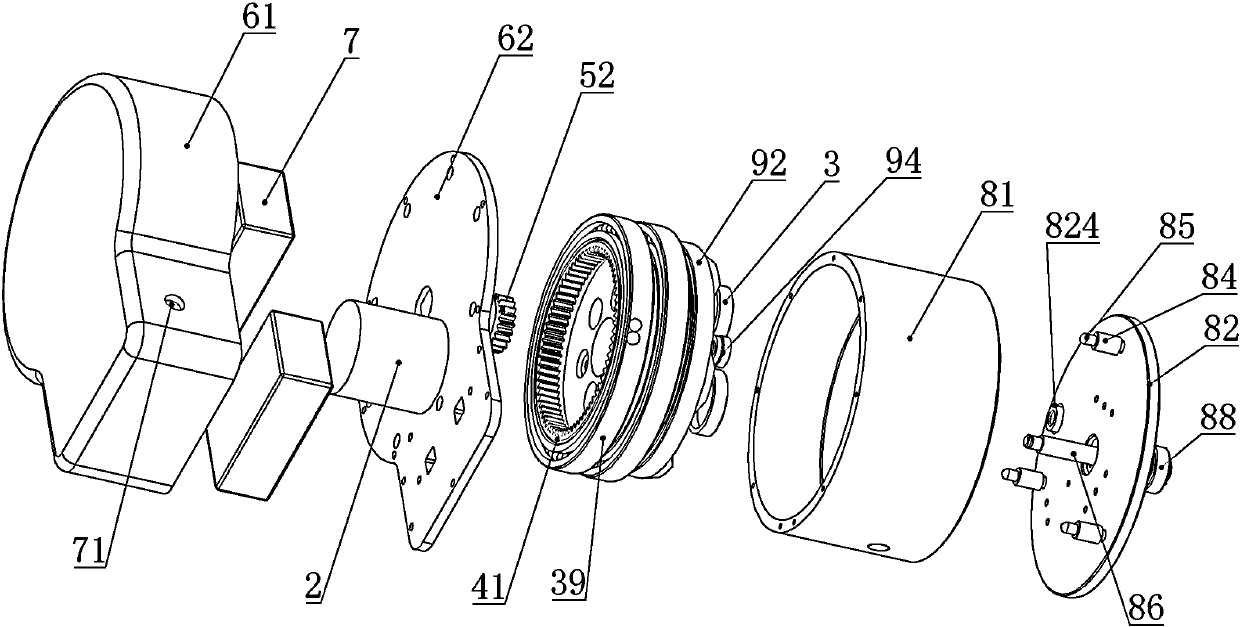

[0035] Embodiments of the optical fiber terminator of the present invention: as Figure 1 to Figure 18 As shown, the optical fiber terminator is an optical fiber terminator for grinding the end face of an optical fiber ferrule. The optical fiber terminator includes a machine base, a grinding motor 1, an indexing tray, an indexing motor 2, a grinding disc 3 and The machine cover, wherein the indexing tray is rotated and assembled in the machine cover through the indexing bearing 39, and there are three grinding discs 3, and the upper disc surfaces of the three grinding discs 3 are respectively provided with rough grinding heads, fine grinding heads and grinding heads with different grinding accuracy. Polishing grinding head, the lower end of the grinding disc 3 is fixed with a rotating shaft 31 mounted on the indexing tray, so that the three grinding discs 3 can revolve with the indexing tray, and a revolution passive ring gear is fixed at the bottom of the indexing tray 41, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com