Automatic gas cylinder filling device and method

A gas cylinder and automatic technology, which is applied in the container filling method, the installation device of the container structure, the container discharge method, etc., can solve the problems of high physical exertion of employees, high risk factor, manual operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

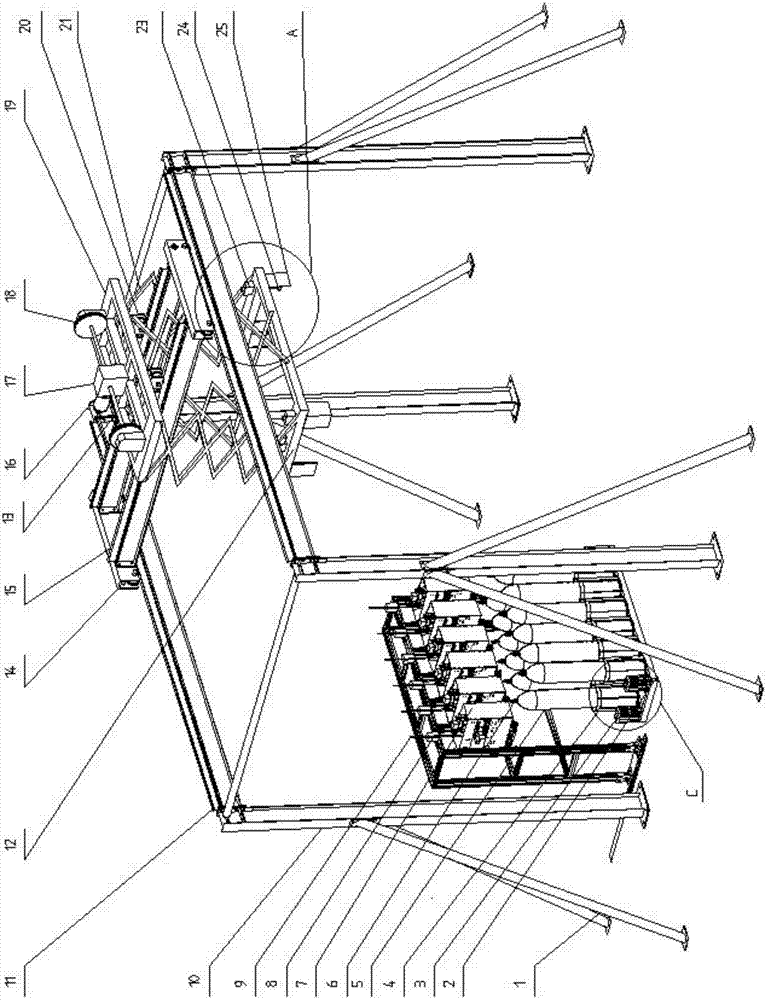

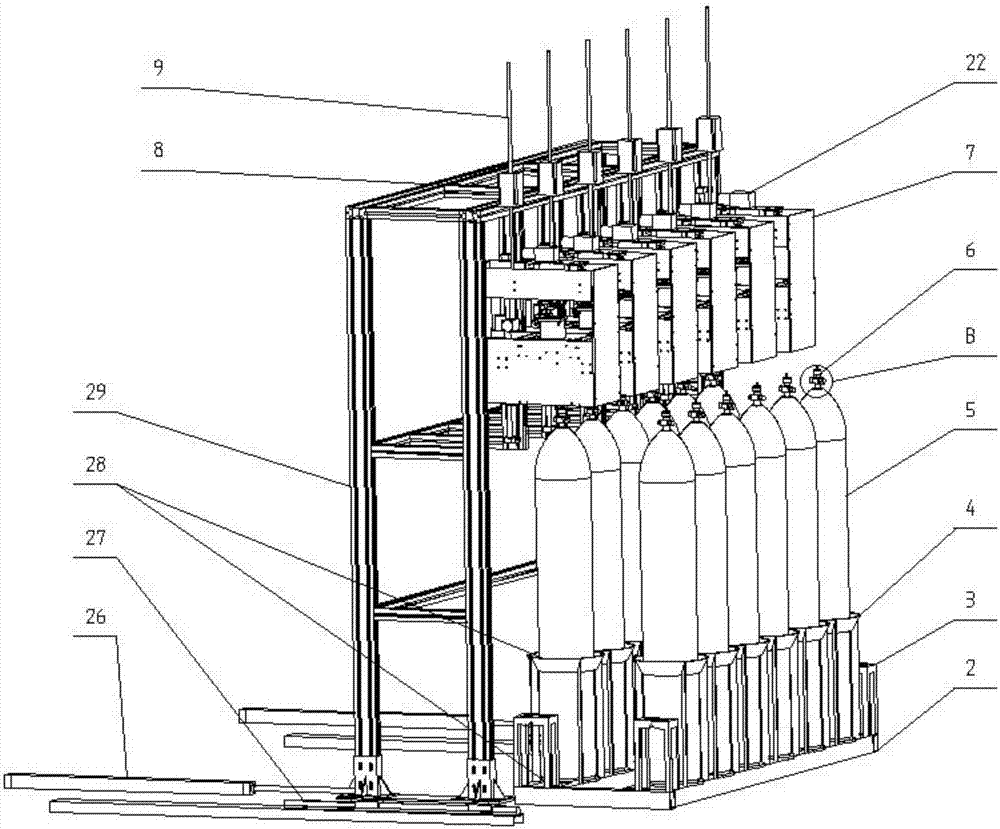

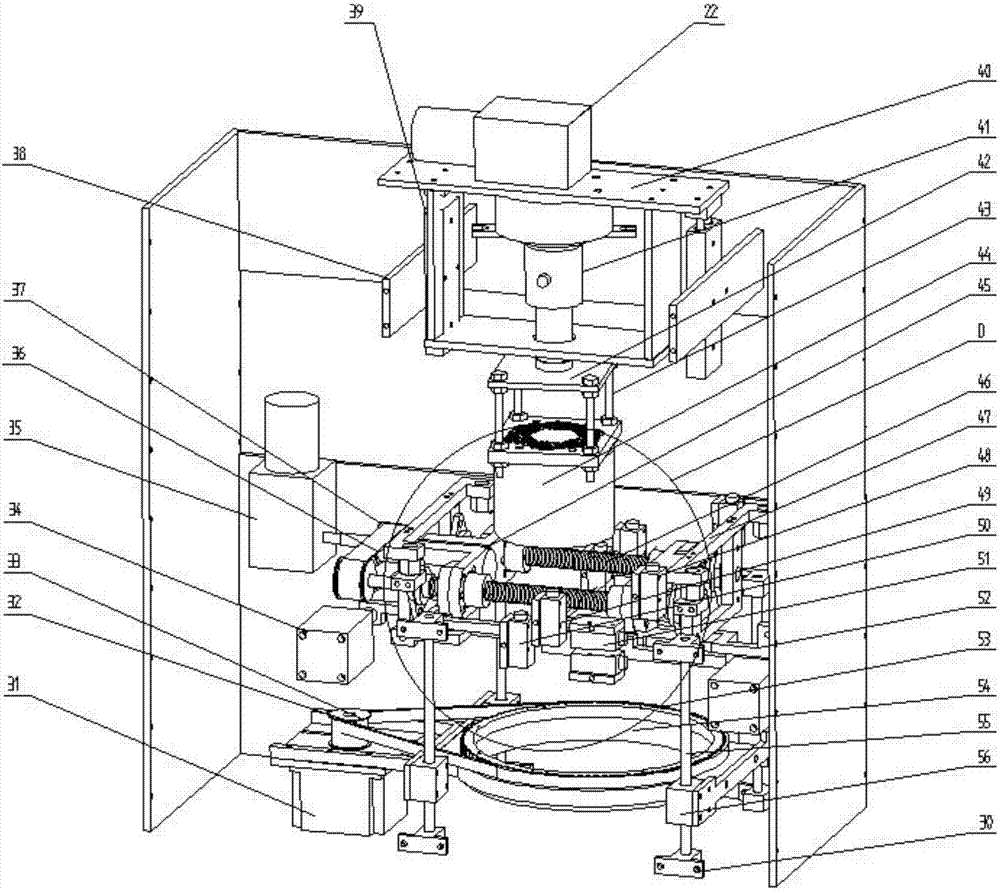

[0041] Such as Figure 1 to Figure 8 The gas cylinder automatic filling device shown includes a filling frame 29, a gas cylinder placement frame 2 and a filling box 7, and is characterized in that a lifting drive mechanism is arranged on the filling frame 29, and the lower end of the lifting drive mechanism is connected to the filling box 7 A bottle valve switch mechanism, a bottle valve detection and filling mechanism and a gas cylinder rotation mechanism are installed in the filling box 7 sequentially. The device also includes a PLC controller, a lifting drive mechanism, a bottle valve switch mechanism, a bottle valve detection and filling mechanism. The loading mechanism and the cylinder rotating mechanism are respectively connected to the PLC controller.

[0042] Both sides of the filling box 7 are provided with slide blocks, and the filling frame 29 is provided with a slide rail. The bar 9 is provided with a nut, and the nut is fixedly arranged on the filling box 7, and ...

Embodiment 2

[0056] The invention provides a method for automatically filling a gas cylinder, the method comprising the following steps:

[0057] The first step: put the gas cylinder 5 on the gas cylinder rack 2;

[0058] The second step: move the gas cylinder rack 2 to the filling position of the gas cylinder 5;

[0059] Step 3: The PLC controller controls the movement of the cylinder 26 to push the filling frame 29 and the filling box 7 on it to the filling position;

[0060] Step 4: The PLC controller controls the lifting drive mechanism and the gas cylinder rotation mechanism to work, and controls the filling box 7 to descend while driving the gas cylinder 5 to rotate. After reaching the set position, the bottle valve detection filling mechanism detects and corrects the direction of the cylinder valve 6 , and along the bottle valve 6;

[0061] Step 5: The PLC controller controls the bottle valve detection and filling mechanism to clamp the bottle valve 6, then controls the bottle val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com